Water-based polymer nano iron oxide dispersing agent and preparation method thereof

A nano-iron oxide and water-based polymer technology, applied in coatings, pigment pastes, etc., can solve problems that restrict the application and development of nano-iron oxide pigments, pigment dispersion problems, compatibility differences, etc., and achieve excellent wetting and anchoring Function, excellent viscosity reducing effect, good viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

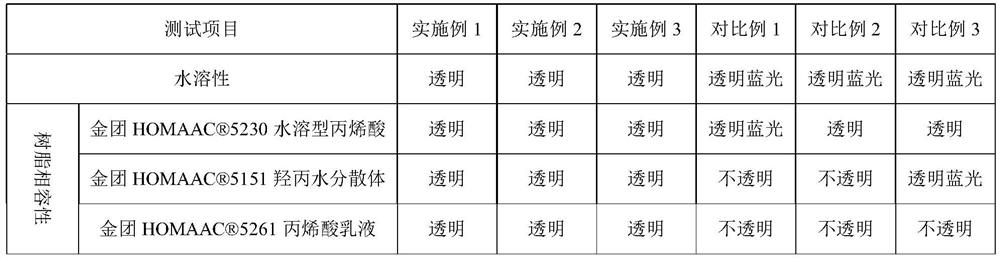

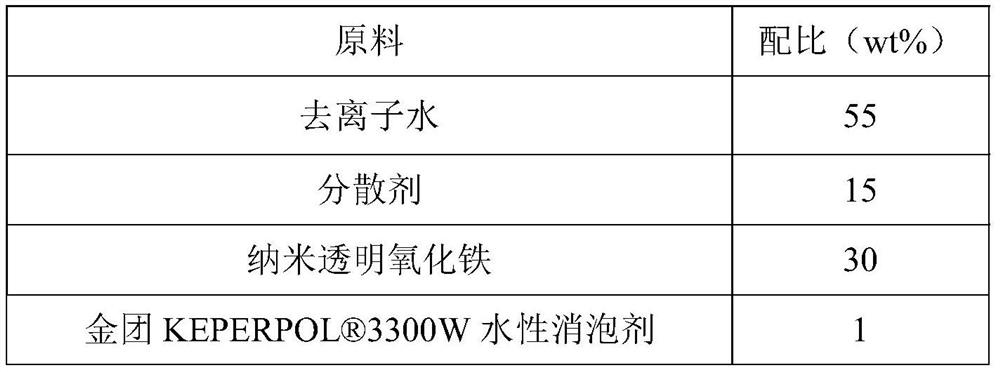

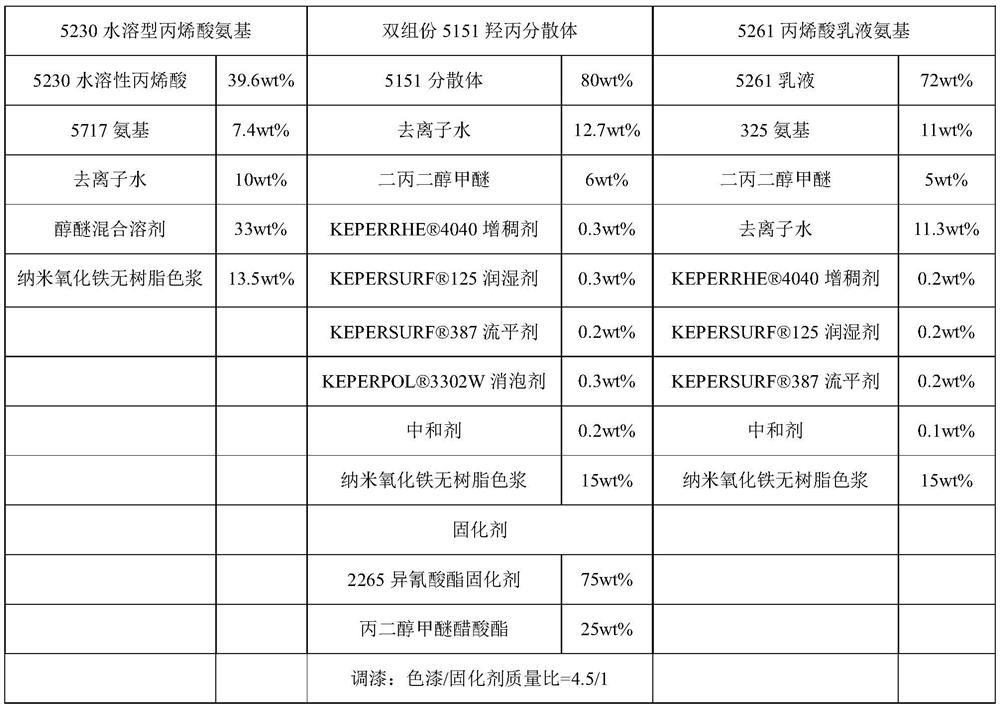

Examples

Embodiment 1

[0024] A water-based polymer nano-iron oxide dispersant, prepared from the following raw materials: trimethylbenzene, butyl acrylate, isooctyl acrylate, styrene, hydroxypropyl acrylate, di-tert-butyl peroxide, M 350 PU, isofor Alone diisocyanate, Borchi Kat 315, phosphorus pentoxide, distilled water, dipropylene glycol methyl ether;

[0025] The preparation method of the dispersant in the present embodiment comprises the following steps:

[0026] S1. Add 50g of trimethylbenzene into a four-necked flask equipped with a stirring and condensing device, and add 2.5g of butyl acrylate, 5g of isooctyl acrylate, 2.5g of styrene, 40g of The mixture of hydroxypropyl acrylate and 1 g of di-tert-butyl peroxide was added dropwise after 4 hours, kept for 3 hours, cooled to 60°C, and filtered to prepare a polyhydroxy acrylic acid copolymer;

[0027] S2. Weigh 25g of M 350 PU into a four-necked flask equipped with a stirring and condensing device, and add 17.47g of isophorone diisocyanate...

Embodiment 2

[0030] A water-based polymer nano-iron oxide dispersant, prepared from the following raw materials:

[0031] Trimethylbenzene, Butyl Acrylate, Isooctyl Acrylate, Styrene, Hydroxypropyl Acrylate, Di-tert-Butyl Peroxide, M 500 PU, Isophorone Diisocyanate, Borchi Kat 315, phosphorus pentoxide, distilled water, dipropylene glycol methyl ether;

[0032] The preparation method of the dispersant of the present embodiment may further comprise the steps:

[0033] S1. Add 50g of trimethylbenzene into a four-necked flask equipped with a stirring and condensing device, and add 7.5g of butyl acrylate, 10g of isooctyl acrylate, 2.5g of styrene, 30g of The mixture of hydroxypropyl acrylate and 0.5g di-tert-butyl peroxide was added dropwise for 3 hours, kept for 2 hours, cooled to 60°C, and filtered to prepare a polyhydroxy acrylic acid copolymer;

[0034] S2. Weigh 25g of M 500PU and add it to a four-necked flask equipped with a stirring and condensing device. At 60°C, under the protection ...

Embodiment 3

[0037] A water-based polymer nano-iron oxide dispersant, prepared from the following raw materials: trimethylbenzene, butyl acrylate, isooctyl acrylate, styrene, hydroxypropyl acrylate, di-tert-butyl peroxide, M 750 PU, isofor Alone diisocyanate, Borchi Kat 315, phosphorus pentoxide, distilled water, dipropylene glycol methyl ether;

[0038] The preparation method of the dispersant of the present embodiment may further comprise the steps:

[0039] S1. Add 50g of trimethylbenzene into a four-necked flask equipped with a stirring and condensing device, and add 7.5g of butyl acrylate, 15g of isooctyl acrylate, 2.5g of styrene, 25g of The mixture of hydroxypropyl acrylate and 0.5g di-tert-butyl peroxide was added dropwise for 3 hours, kept for 2 hours, cooled to 60°C, and filtered to prepare a polyhydroxy acrylic acid copolymer;

[0040] S2. Weigh 25g of M 750 PU into a four-necked flask equipped with a stirring and condensing device, and add 8.15g of isophorone diisocyanate dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com