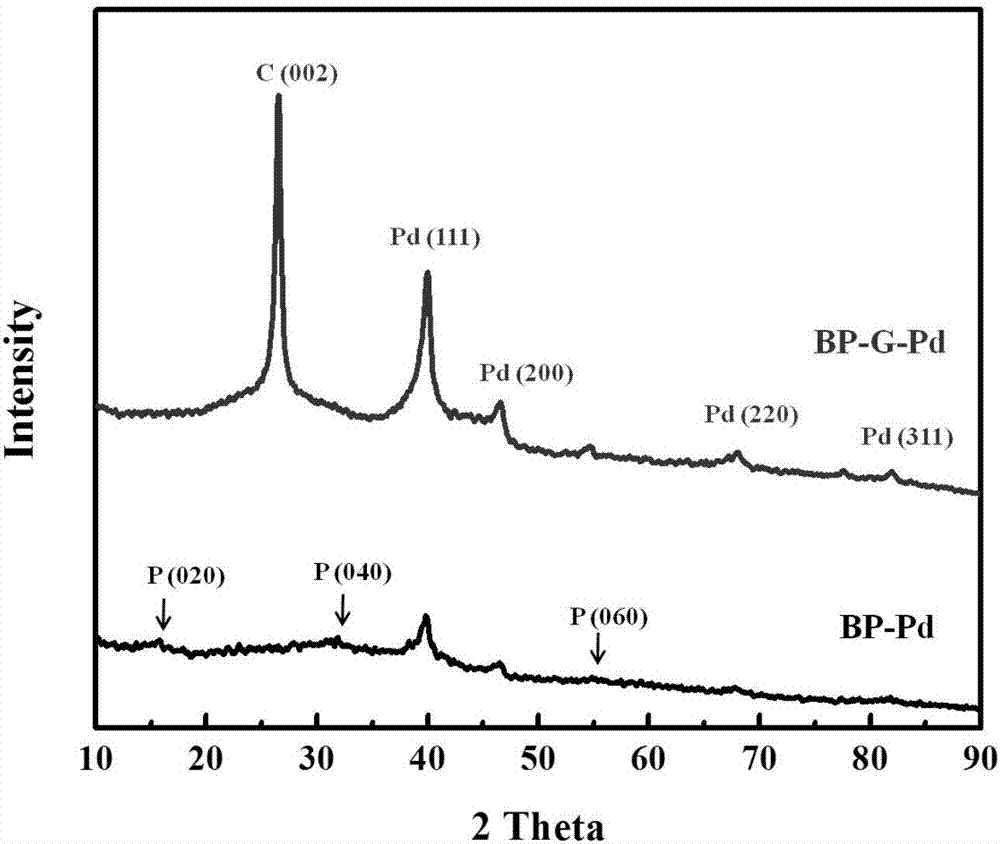

Preparation method of black phosphorus graphene composite material-loaded noble metal nanoparticles

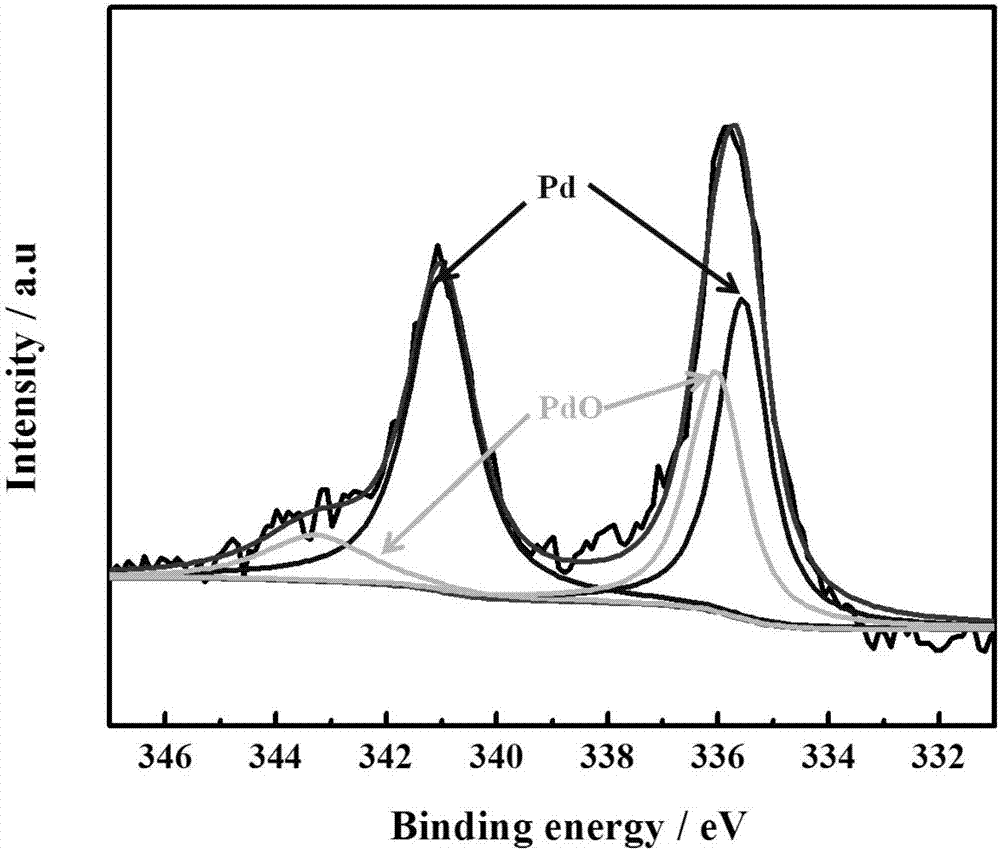

A technology of graphene nanosheets and composite materials, which is applied in the field of materials science, can solve the problems of high price and low catalytic activity of catalysts, achieve the effect of simple and clear preparation process, and improve electrochemical activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of black phosphorus graphene composite material loaded noble metal nanoparticles, specifically comprising the following steps:

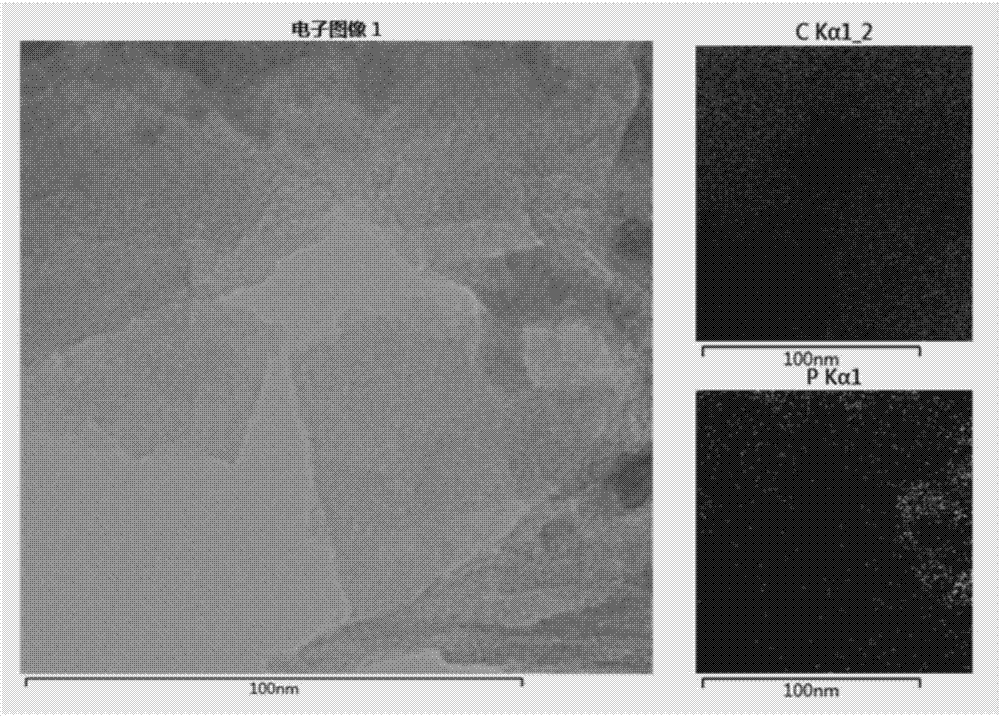

[0025] (1) Preparation of black phosphorus graphene composites

[0026] ① Preparation of black phosphorus: Add 2g of red phosphorus and 15mL of ultrapure water into a 25mL hydrothermal kettle at room temperature, and steam at 200°C for 12 hours to remove the oxide layer on the surface of red phosphorus. Then take it out and dry it, grind it with an agate mortar for 0.5-1h, and then perform mechanical ball milling on the multi-layer black phosphorus precursor under normal temperature and pressure with argon protection, ball milling for 24-48h, and keep the rotation speed at 500r / min. Black phosphorus is obtained after mechanical ball milling.

[0027] ② Activation method of graphene: Soak graphene in 6 M potassium hydroxide solution for 12 h, centrifuge the obtained sample with deionized water and absolute ethanol, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com