Vibratory layering fertilization furrower with staggered four rods

A layered fertilization and trench opener technology is applied in fertilization devices, fertilizer distributors, excavation/covering trenches, etc., which can solve the problem of increasing soil tillage resistance, uneven spatial distribution of fertilizers, and insignificant layering effects. problems, to reduce soil tillage resistance and lateral tillage resistance, wide applicability, simple and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

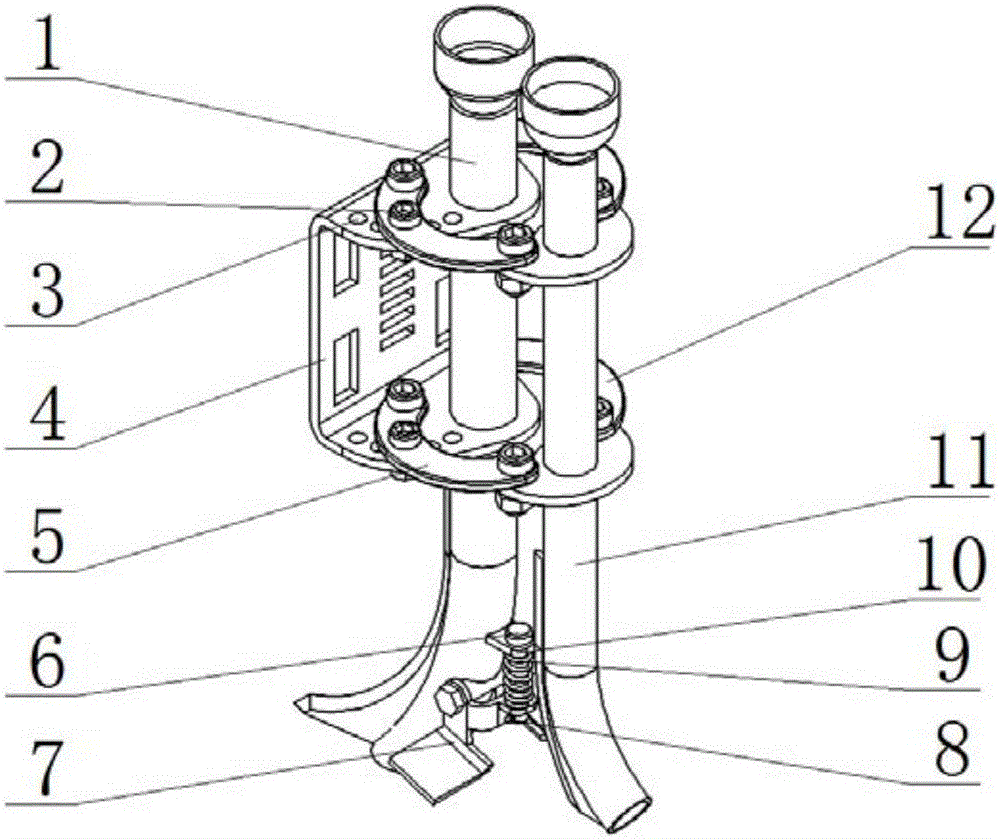

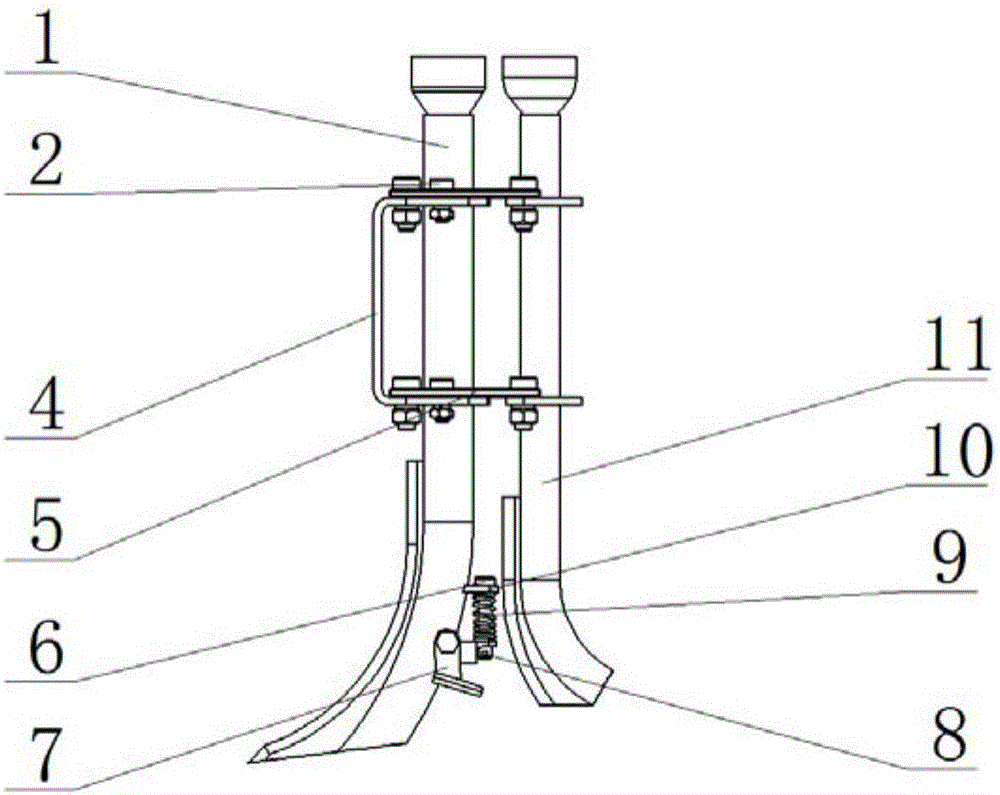

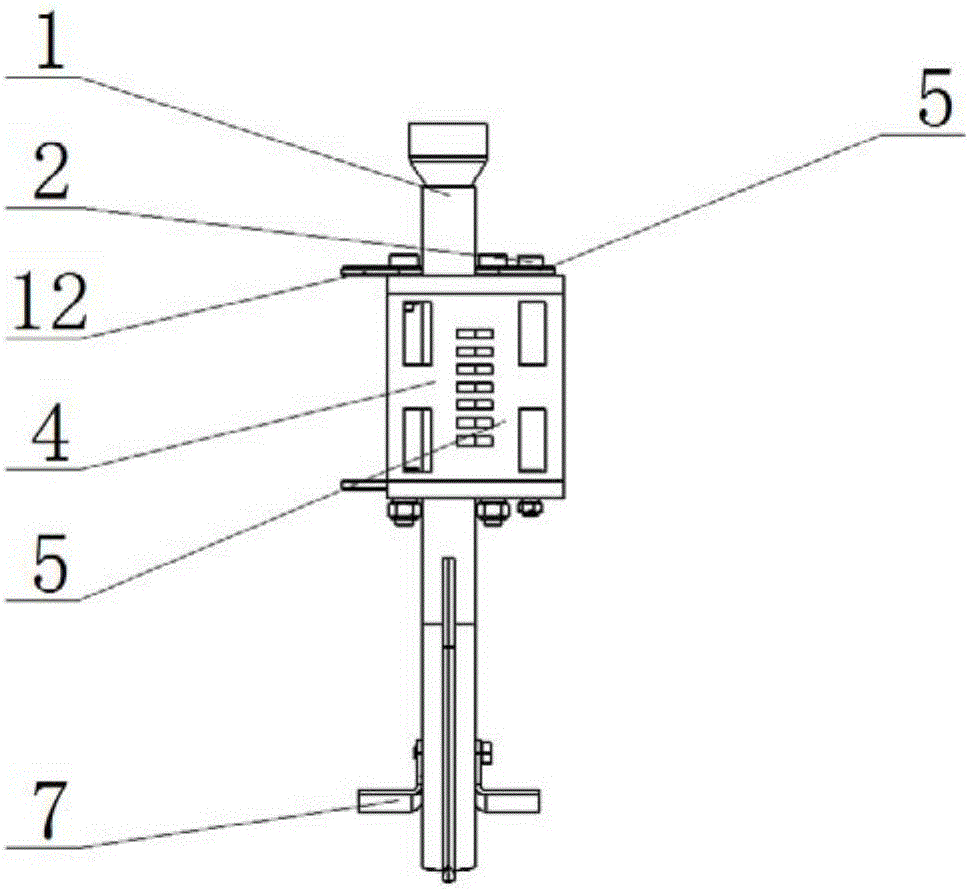

[0012] Below in conjunction with accompanying drawing, the embodiment that the present invention creates is described in detail:

[0013] The main opener 1 is fixed in the main frame 4, and the main frame 4 is hinged to the tail opener 11 through the left and right ring connecting rods 5 and 12, and the left ring connecting rod 5 is connected to the main frame through the adjusting bolt 2. The positioning hole 3 on the frame 4 is connected, and the lower rear part of the main opener 1 is hinged with a vibrating blade 7 that is high in the front and low in the rear. It is connected with the orifice plate 10 fixed in the lower rear part of the main opener 1 .

[0014] The ditch opener is connected with the seeder through the main frame. When working, it advances with the seeder. First, the main ditch 1 enters the soil and divides the soil to open the ditch and apply deep fertilizer. The upper rear part of the vibrating blade 7 is connected with the orifice plate 10 fixed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com