Method for building backflow-free multi-stage AO<+> digestion method-based village sewage treatment facility

A construction method and non-reflux technology, applied in the direction of water/sewage multi-stage treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of adding various structures, large power consumption, and large infrastructure investment, etc., to achieve Long service life, cost saving, easy to obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

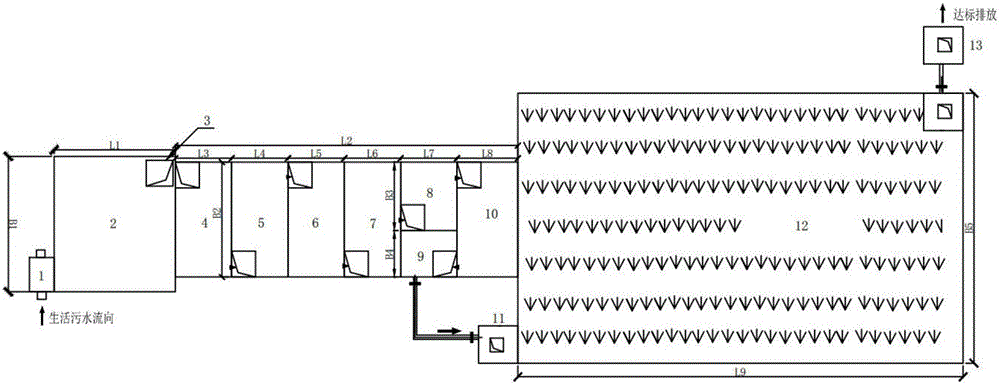

[0029] (1) No backflow multi-stage AO + ecological consumption method to treat village and town sewage flow Q = 24m 3 / d. Its sump 2 length L1=4.50m, width B1=2.50m, height H=2.50m; Anaerobic pond 4 length L3=1.20m, width B2=2.20m, height H=2.50m; Aerobic pond 5 length L4 =1.20m, width B2=2.20m, height H=2.50m; anaerobic pool 6 length L5=1.20m, width B2=2.20m, height H=2.50m; aerobic pool 7 length L6=1.20m, width B2 =2.20m, height H=2.50m; Settling tank 8 length L7=1.20m, width B3=1.10m, height H=2.50m; Disinfection discharge pond 9 length L7=1.20m, width B4=1.10m, height H= 2.50m; length L8=1.20m of the sludge tank 10, width B2=2.20m, height H=2.50m.

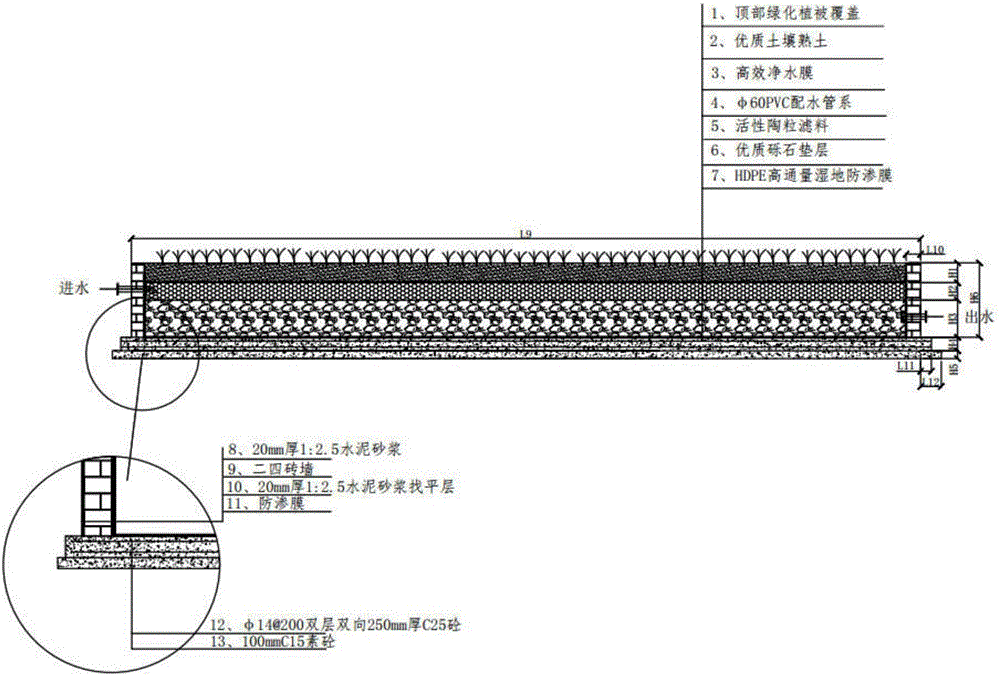

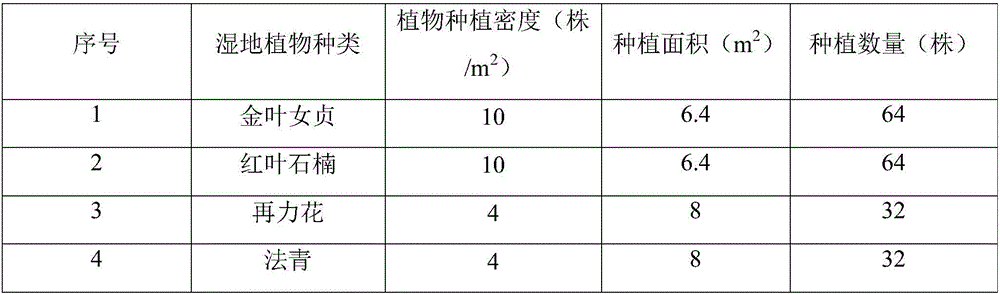

[0030] (2) Subsurface constructed wetland mainly consists of water distribution system, waterproof layer laying, cushion laying, wall construction, plant arrangement, etc. The area of subsurface wetland is A=Q*1.2, length L9=6.00m, width B5=4.80m , height H6=1.40m.

[0031] (3) Lay 100mm plain soil, 200mm thick gravel cus...

Embodiment 2

[0038] (1) Non-reflux multi-stage AO + ecological consumption method to treat village and town sewage flow Q = 48m 3 / d. Its sump 2 length L1=6.00m, width B1=3.50m, height H=2.50m; Anaerobic pond 4 length L3=1.80m, width B2=2.80m, height H=2.50m; Aerobic pond 5 length L4 =1.80m, width B2=2.80m, height H=2.50m; anaerobic pool 6 length L5=1.80m, width B2=2.80m, height H=2.50m; aerobic pool 7 length L6=1.80m, width B2 =2.80m, height H=2.50m; Settling tank 8 length L7=1.80m, width B3=1.40m, height H=2.50m; Disinfection discharge tank 9 length L7=1.80m, width B4=1.40m, height H= 2.50m; length L8=1.80m of the sludge tank 10, width B2=2.80m, height H=2.50m.

[0039] (2) Subsurface constructed wetland mainly consists of water distribution system, waterproof layer laying, cushion laying, wall construction, plant arrangement, etc. The area of subsurface wetland is A=Q*1.2, length L9=8.00m, width B5=7.20m , height H6=1.40m.

[0040] (3) Lay 100mm plain soil, 200mm thick gravel cushio...

Embodiment 3

[0047] (1) Non-reflux multi-stage AO + ecological consumption method to treat village and town sewage flow Q = 96m 3 / d. Its sump 2 length L1=10.00m, width B1=4.00m, height H=2.50m; Anaerobic pond 4 length L3=4.00m, width B2=3.60m, height H=2.50m; Aerobic pond 5 length L4 =4.00m, width B2=3.60m, height H=2.50m; anaerobic pool 6 length L5=4.00m, width B2=3.60m, height H=2.50m; aerobic pool 7 length L6=4.00m, width B2 =3.60m, height H=2.50m; Settling tank 8 length L7=4.00m, width B3=1.80m, height H=2.50m; Disinfection discharge tank 9 length L7=4.00m, width B4=1.8m, height H= 2.50m; length L8=4.00m of the sludge tank 10, width B2=3.60m, height H=2.50m.

[0048] (2) Subsurface flow artificial wetland mainly consists of water distribution system, waterproof layer laying, cushion laying, wall construction, plant arrangement, etc. The area of subsurface flow wetland is A=Q*1.2, length L9=14.00m, width B5=8.23m , height H6=1.40m.

[0049] (3) Lay 100mm plain soil, 200mm thick g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com