Preparation method for iron-nickel-molybdenum soft magnetic alloy sheet

A technology of soft magnetic alloys and alloy flakes, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve problems such as poor performance, large material and energy loss, and many impurities, so as to reduce production costs, reduce alloy oxidation, simplify The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

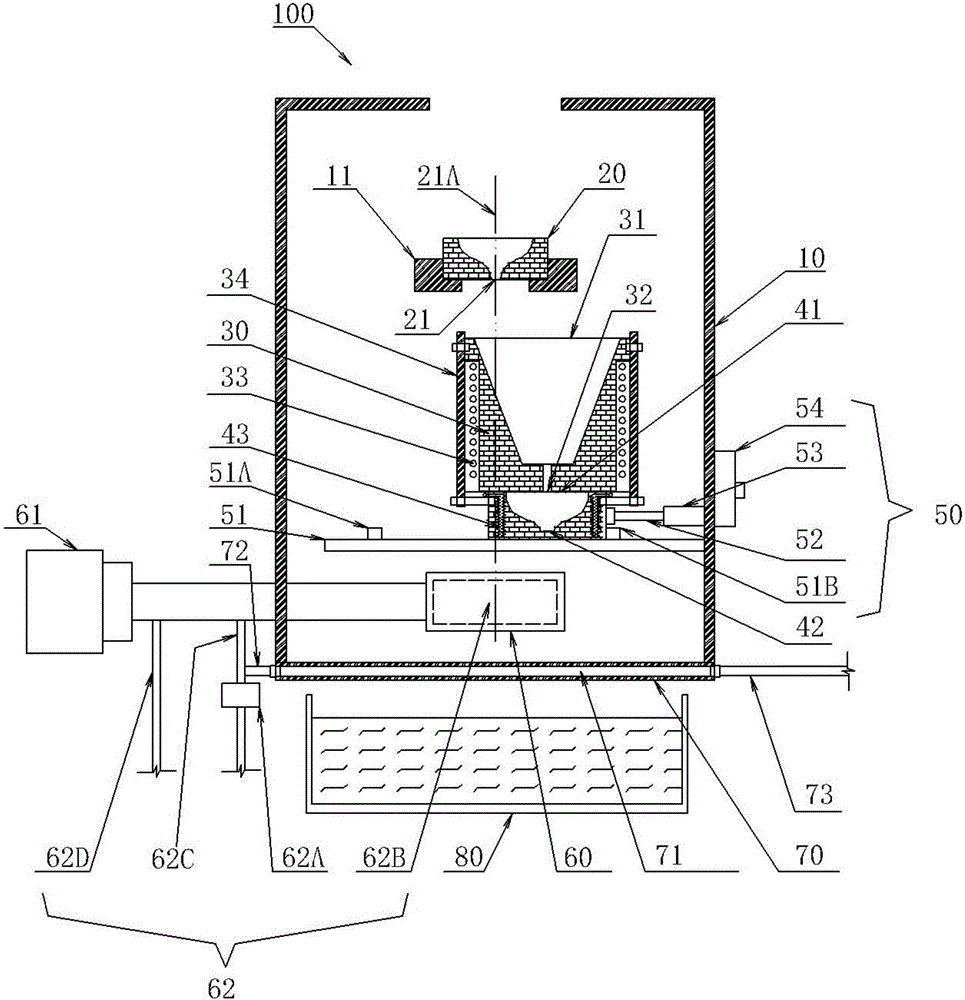

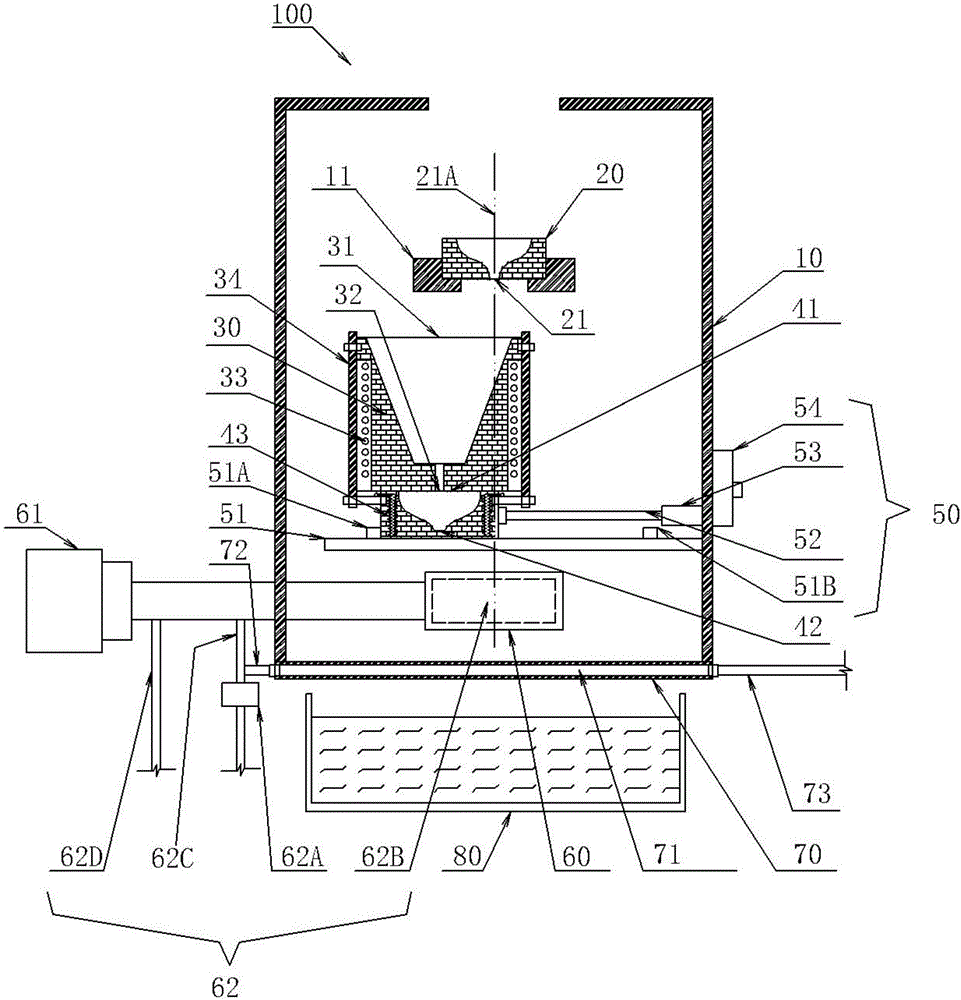

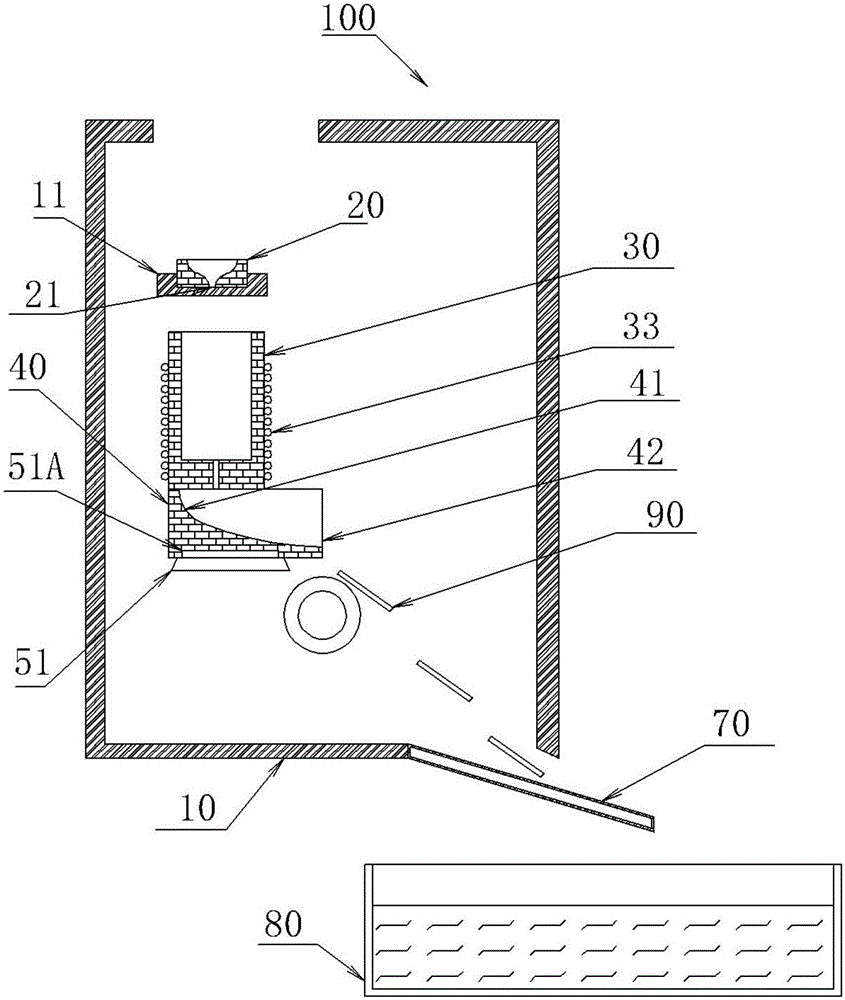

[0030] A kind of iron-nickel-molybdenum soft magnetic alloy flake preparation method provided in this embodiment, using Figure 1~3 Alloy flake pouring apparatus 100 shown in . The alloy flake pouring device 100 includes a box body 10 , a funnel brick 20 , a tundish 30 , a chute 40 , a driving mechanism 50 , a quick-setting roller 60 , a condensation plate 70 and a cooling water tank 80 . The inner wall of the box body 10 is fixed with a bracket 11 made of non-magnetic steel plate by screws; a round funnel brick 20 with a height of 100mm sintered by refractory material is erected on the bracket 11, and its top is a wide funnel brick with a diameter of 200mm. The bottom is provided with a funnel hole 21 with a diameter of 25 mm. A 400 mm high flat barrel-shaped tundish 30 made of refractory material, the tundish 30 is provided with a pouring channel with a major axis of an oval upper opening 31 of 650 mm and a diameter of a circular lower opening 32 of 25 mm and An induction ...

Embodiment 2

[0045] This embodiment provides a method for preparing iron-nickel-molybdenum soft magnetic alloy flakes, in which an alloy flake pouring device is used, which is similar to the alloy flake pouring device in Example 1, but without condensation The plate 70 is slightly different in other dimensions, which will not be repeated here.

[0046] The preparation method of the iron-nickel-molybdenum soft magnetic alloy sheet provided in this embodiment comprises the following steps:

[0047] S10: melting iron and molybdenum in a vacuum induction smelting furnace with a mass ratio of 1:1.1, and then pouring into a molybdenum-iron master alloy block;

[0048] S20: Melt 80% of nickel, 0.08% of phosphorus, 0.22% of sulfur and 14.7% of smelted pure iron in the induction smelting furnace according to the mass percentage; The molybdenum-iron master alloy block that S10 makes adds described induction smelting furnace and melts, and begins to heat tundish 30 and chute 40; In an alternative em...

Embodiment 3

[0058] This embodiment provides a method for preparing iron-nickel-molybdenum soft magnetic alloy flakes, wherein an alloy flake pouring device is used, and the alloy flake pouring device is similar to the alloy flake pouring device in Embodiment 2, and details are not repeated here .

[0059] A method for preparing an iron-nickel-molybdenum soft magnetic alloy sheet provided in this embodiment includes the following steps:

[0060] S10: melting iron and molybdenum in a vacuum induction smelting furnace with a mass ratio of 1:1, and then pouring into a molybdenum-iron master alloy block;

[0061] S20: Melt 85% nickel, 0.05% phosphorus, 0.45% sulfur and 12.5% smelted pure iron in the induction smelting furnace according to the mass percentage; The molybdenum-iron master alloy block that S10 makes adds described induction smelting furnace and melts, and starts to heat tundish 30 and chute 40; In an alternative embodiment, the mass percent of phosphorus and sulfur in this step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com