High-transmittance dustproof screen window material and preparation method of novel screen window

A screen and dust-proof technology, applied in insect control, rayon manufacturing, filament/thread forming, etc., can solve the problem that the PM2.5 interception efficiency is only 0-5%, the PM2.5 interception efficiency is less than 40%, and the nanofiber The low strength of the screen window can achieve the effect of good decorative effect, excellent wind resistance and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

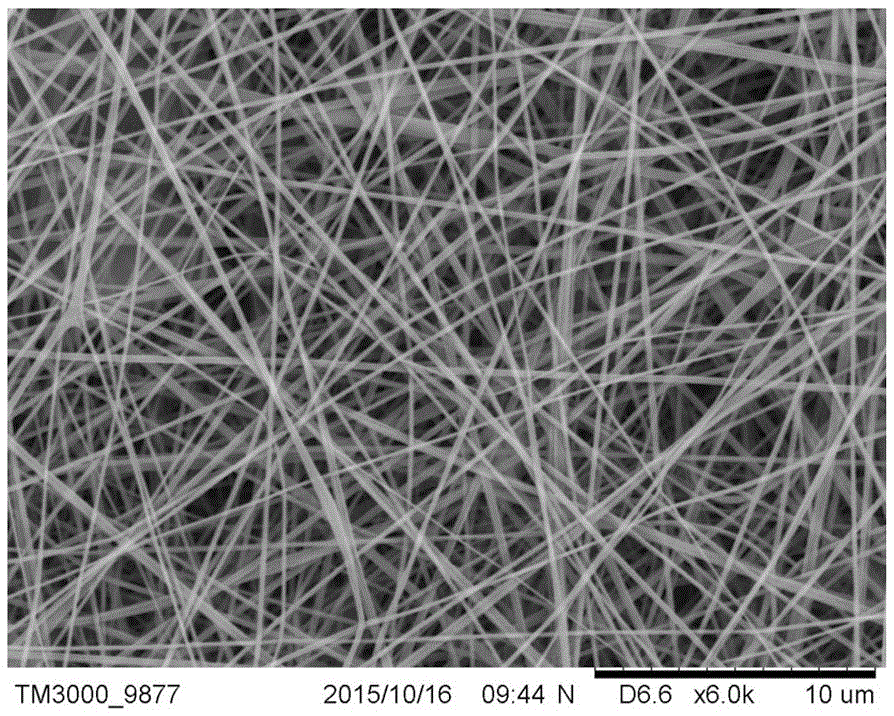

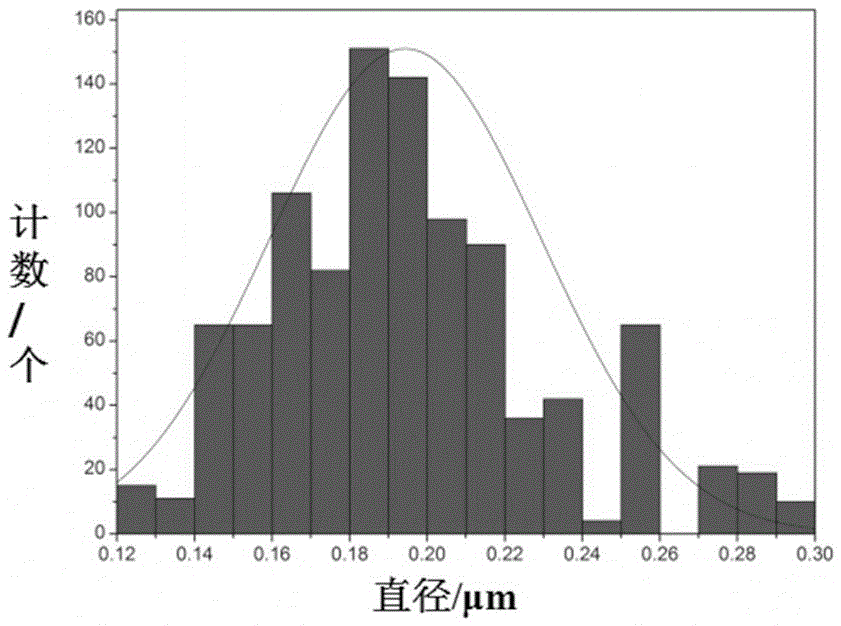

[0026] Dissolve a certain amount of polyacrylonitrile in N,N-dimethylformamide, stir for 5-8 hours until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide spinning solution. Add 0.5% tourmaline particles to the prepared homogeneous spinning solution, and stir in a water bath at 40°C for 3 hours. The spinning parameters are: voltage 55-70KV, receiving distance 10-20cm, drum speed 60r / min, ambient temperature 25°C, ambient relative humidity 45%.

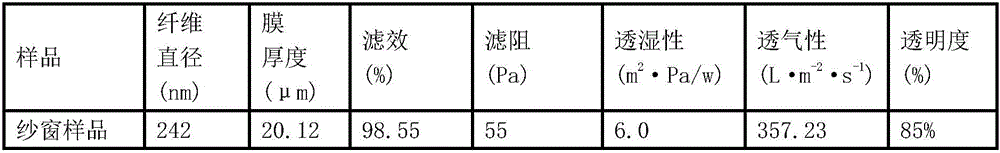

[0027] Among them, the base cloth is made of glass fiber gauze, and the cover cloth is made of hard PET perforated material. The obtained base cloth / nanofiber film / cover cloth is heat-treated, and finally the gauze is cut and embedded in the frame to make a screen window. Test the nanofiber diameter, nano film thickness, filtration efficiency, filtration resistance, moisture permeability, air permeability and transparency of the screen window. The test data are shown in Table 1.

[0028] Table 1

[0029]

Embodiment 2

[0031] Dissolve a certain amount of polyacrylonitrile in N,N-dimethylformamide, stir for 5-8 hours until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide spinning solution. Add 1.5% tourmaline particles to the prepared homogeneous spinning solution, and stir in a water bath at 40°C for 8 hours. The spinning parameters are: voltage 70KV, receiving distance 10cm, drum rotation speed 50r / min, ambient temperature 27°C, ambient relative humidity 45%.

[0032] Among them, the base fabric is made of ordinary nylon gauze, and the cover fabric is made of hard PA perforated material. The obtained base fabric / nanofiber film / cover fabric is heat-treated, and finally the gauze is cut and embedded in the frame to make a screen window. Test the nanofiber diameter, nano film thickness, filtration efficiency, filtration resistance, moisture permeability, air permeability and transparency of the screen window. The test data are shown in Table 2.

[0033] Table 2

[003...

Embodiment 3

[0036] Dissolve a certain amount of polyvinylidene fluoride in N,N-dimethylformamide, stir for 5-8 hours until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide spinning solution. Add 1% tourmaline particles to the prepared homogeneous spinning solution, and stir in a water bath at 40° C. for 6 hours. Electrospinning parameters are: voltage 65KV, receiving distance 12cm, drum rotation speed 40r / min, ambient temperature 25°C, and ambient relative humidity 40%.

[0037] Among them, the base fabric is made of transparent hard perforated PU material, and the cover fabric is made of ordinary nylon gauze. The obtained base fabric / nanofiber film / cover fabric is heat-treated, and finally the gauze is cut and embedded in the frame to make a screen window. The nanofiber diameter, nanofilm thickness, filtration efficiency, filtration resistance, moisture permeability, air permeability and transparency of the screen window were tested, and the test data are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com