Mortar leakage repair method for damage of hinged seal structure based on shield machine

A technology for joint sealing and structural damage, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of difficult operation, long construction period and high cost, and achieve good sealing effect, low construction cost and short construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

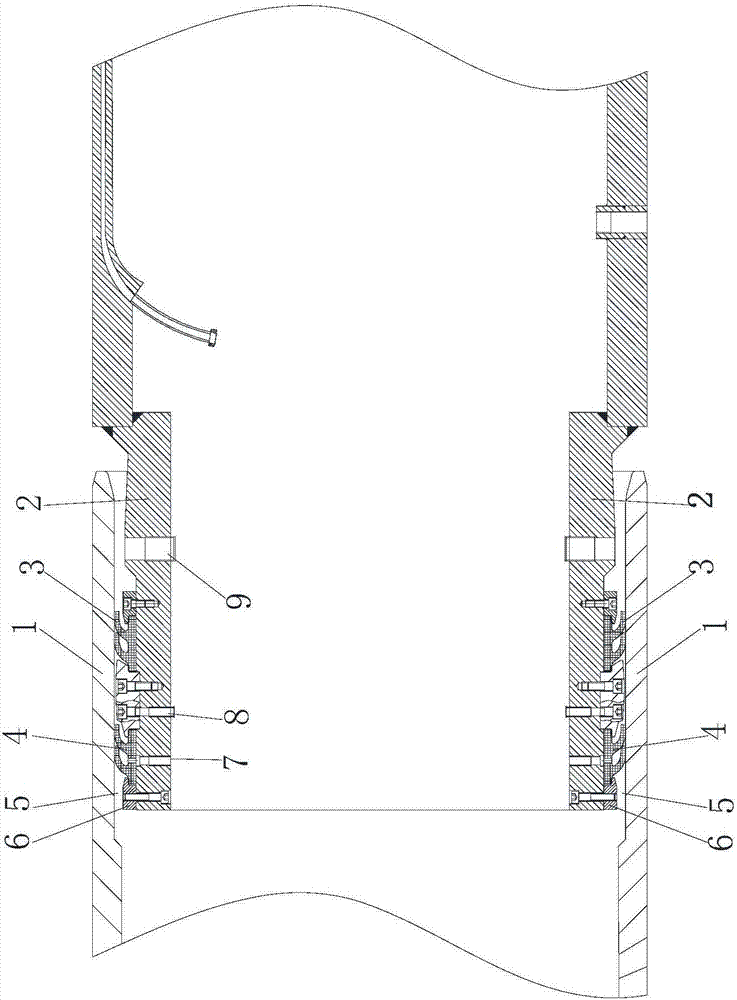

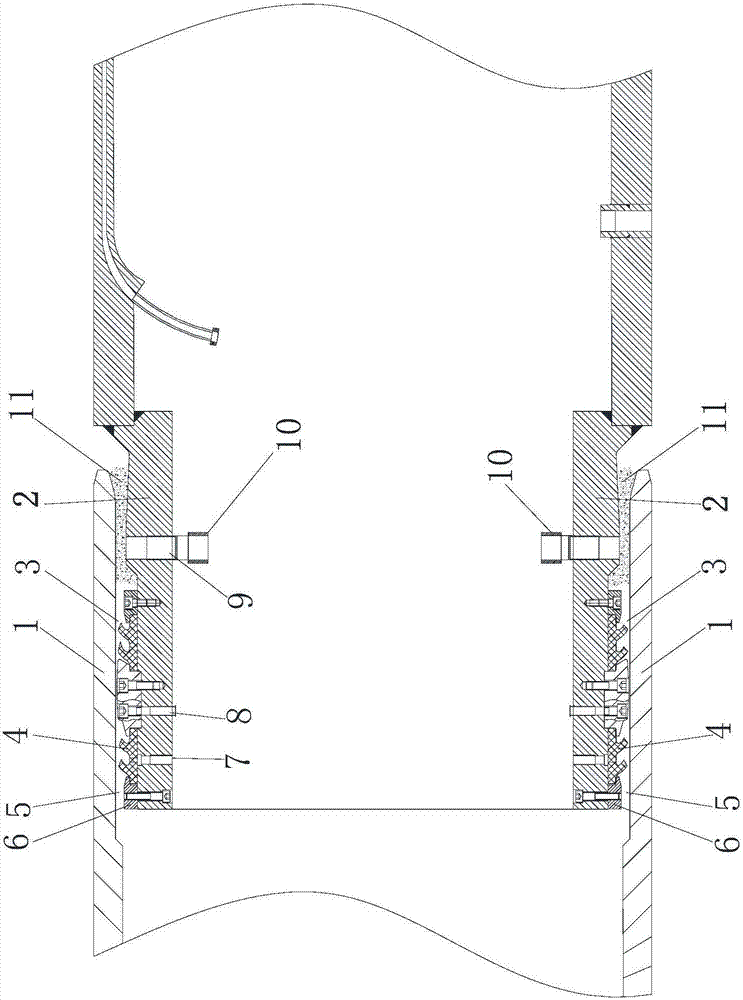

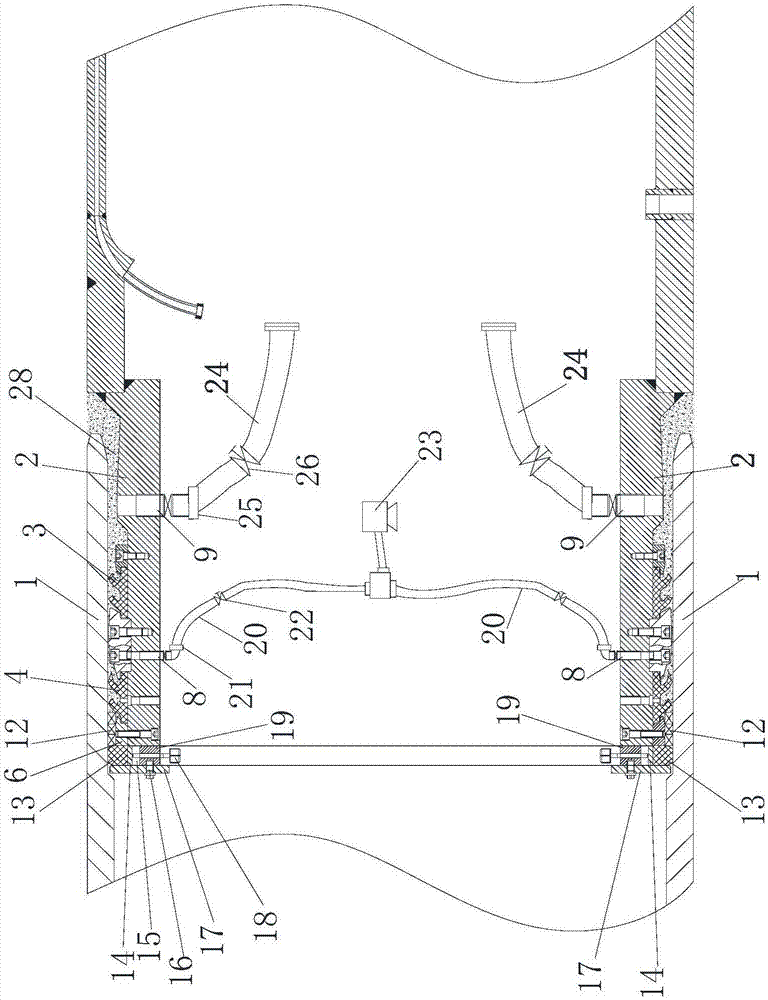

Method used

Image

Examples

Embodiment

[0073] Step 1. The shield machine is shut down, and then a pipe joint 10 is installed in the emergency hole 9 of the shield tail 2, and polyurethane is injected into the joint between the middle shield 1 and the shield tail 2 through the pipe joint 10, and the injected polyurethane expands to form Isolation layer 11.

[0074] Step 2: Clean up the muddy water between the hinged fixing ring 6 and the inner wall of the middle shield 1, and then install the packing 12 in the first chamber 5 between the hinged fixing ring 6 and the inner wall of the middle shield 1.

[0075] Step 3: install a plurality of fan-shaped panels sequentially along the circumferential direction of the end face of the shield tail 2, the plurality of fan-shaped panels form a shield tail extension steel ring, and a second chamber 15 is formed between the shield tail extension steel ring and the inner wall of the middle shield 1, The second chamber 15 is an annular chamber.

[0076] Step 4. First, measure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com