Applicable ion type flexible humidity sensor and preparation method and application thereof

A humidity sensor, ion-type technology, applied in the field of sensors, can solve the problems of unsatisfactory stability and reliability, and achieve the effect of simple and controllable preparation process and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In some preferred embodiments, the preparation method further includes: coating a biocompatible material at least on the first surface of the flexible substrate and a partial surface of the electrode to form a flexible protective layer, and making the The flexible protective layer, electrodes, sensitive layer and flexible substrate form an integrated structure.

[0057] Further, the polymer includes polyvinyl alcohol, but is not limited thereto.

[0058] Further, the inorganic salt includes any one or a combination of two or more of sodium sulfate, sodium hydroxide, sodium bicarbonate, potassium sulfate, potassium hydroxide, and potassium bicarbonate, but is not limited thereto.

[0059] Further, the modified filler includes any one or a combination of two or more of montmorillonite, kaolin, polypropylene, sodium polyacrylate, and polyacrylamide, but is not limited thereto.

[0060] In some embodiments, the preparation method may further include: mixing inorganic salts...

Embodiment 1

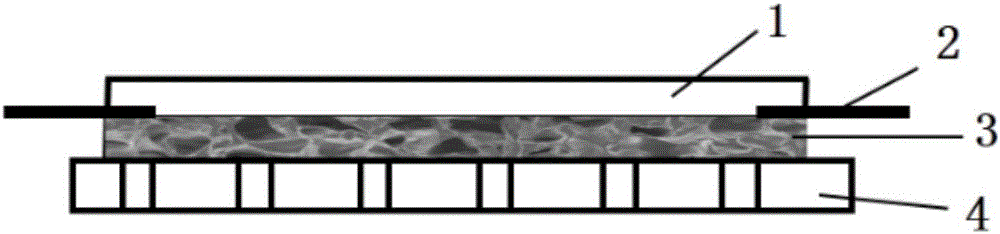

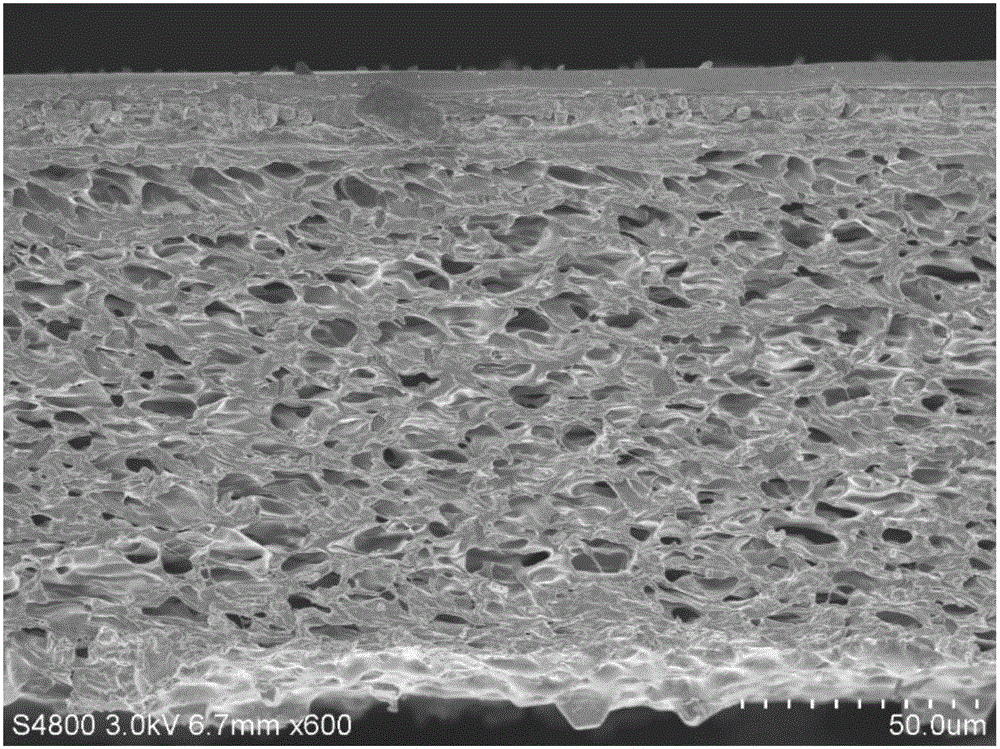

[0083] Example 1: Weigh 6g of PVA and 3g of potassium hydroxide into a flask filled with 60mL of deionized water, stir at 85°C until completely dissolved, then add 0.5g of polypropylene and polyacrylamide mixture to continue To mix evenly, obtain modified PVA gel electrolyte solution (see figure 2 transparent solution in ), the sensitive layer is obtained after removing moisture by drying, natural drying, etc., see figure 2 As shown, the results show that there are a large number of porous structures inside the film (see image 3 shown), which is beneficial to the adsorption of water molecules and the rapid movement of ions in the electrolyte, which can improve the response rate and response range of the sensitive layer. On this basis, by drawing two electrodes on the surface of the sensitive layer, and coating the electrode layer and the surface of the sensitive layer with a material with good biocompatibility (such as silica gel), after forming a protective layer, the var...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com