Garbage disposal device capable of automatically cleaning cutter and working method of garbage disposal device

A garbage disposal device and automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, heating devices, etc., can solve problems affecting the working environment, knives are easy to stick to debris, and easy to produce odors, etc., to improve work environment, facilitate follow-up operations, and increase the effect of cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

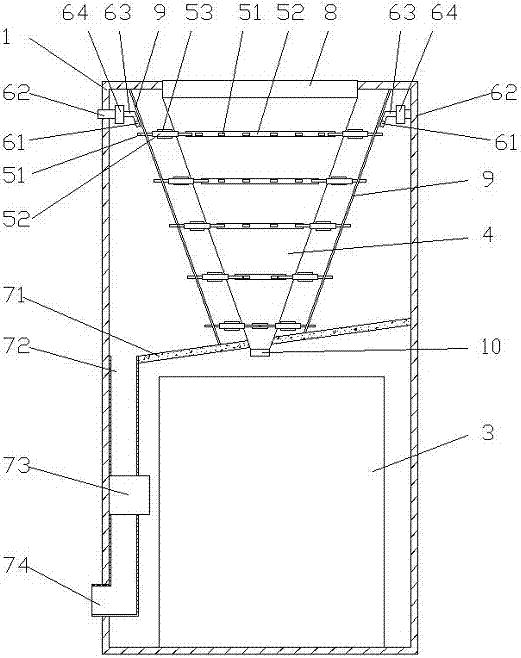

[0030] reference Figure 1-2 , figure 1 A cross-sectional view of a garbage disposal device for automatically cleaning tools provided by the present invention; figure 2 A partial schematic diagram of the garbage crushing device 5 of a garbage disposal device for automatically cleaning cutters provided by the present invention.

[0031] Specifically, a garbage disposal device that automatically cleans knives includes: a housing 1, a feed port 22, a collection box, and a working bucket 4, and also includes a garbage crushing device 5, a knife cleaning device 6, and a waste water collection device 7; The feed port 22 is provided on the housing 1, and the feed port 22 further includes a feed cover 8; the working hopper 4 is provided in the housing 1, and the feed port 22 is located above the working hopper 4. The collection box is located below the working bucket 4; the garbage crushing device 5 includes a crushing knife 51, a number of transmission chains 52, a transmission wheel 5...

Embodiment 2

[0038] reference image 3 , image 3 A cross-sectional view of another garbage disposal device for automatically cleaning cutters provided by the present invention.

[0039] As a preferred mode of the present invention, the crushing knife 51 includes a knife shape with multiple functions, which includes cutting, crushing, grinding, etc. from top to bottom.

[0040] As a preferred mode of the present invention, any functional knife type is provided on at least two transmission chains 52.

[0041] As a preferred mode of the present invention, it further includes a stirring rod 11, a heating tube 12, and a second driving motor 13. The stirring rod 11 is arranged in the collection box 3, and the heating tube 12 is arranged on the stirring rod 11, The stirring rod 11 is connected to the second driving motor 13.

[0042] As a preferred mode of the present invention, a deodorizing device 14 is further included, and the deodorizing device 14 is arranged inside the feed port 22 and above the c...

Embodiment 3

[0048] Reference map

[0049] As a preferred mode of the present invention, it includes the following steps:

[0050] S001: The operator pours garbage into the feed inlet 22, and operates the garbage disposal device to start working;

[0051] S002, the first driving motor 54 drives the transmission wheel 53 to rotate, the transmission wheel 53 drives the transmission chain 52 to work, the crushing knife 51 cuts the poured garbage, and the crushed garbage falls into the collection box 3;

[0052] S003, the water pump 64 works, and the water in the water inlet pipe 62 enters the water spray pipe 63 through the water pump 64 and then is sprayed out by the spray head 61, and the spray head 61 cleans the residue on the crushing knife 51 by spraying water;

[0053] S004: The collection table 71 collects and cleans the waste water of the crushing knife 51 and collects it through the collecting pipe 72. The waste water is filtered through the filter layer 73, and the liquid water is discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com