Surface preparation method combining wave forms and chemical gradients

A chemical gradient, wave-like technology, applied in chemical instruments and methods, laboratory containers, lamination devices, etc., can solve the problems of inability to achieve precise directional wetting and performance needs to be improved, and achieve economical and reliable preparation methods. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

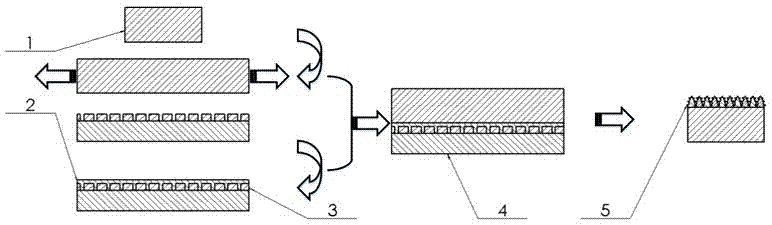

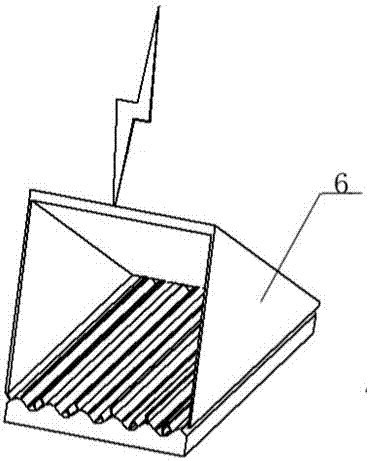

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

[0020] Refer to attached picture. This embodiment includes the following steps: Step (1) Prepare the coating solution: mix 5g of polydimethylsiloxane solution with 0.5g of crosslinking agent, then place it in a vacuum drying oven and use a vacuum pump to extract it for 20 minutes to remove the Bubbles, the coating solution of polydimethylsiloxane is obtained;

[0021] Step (2) Prepare the mask: take a silicon template with a length of 50mm, a width of 25mm, and a thickness of 1mm, and use a three-dimensional drawing software to draw the layout of the groove structure. The unit groove array, the width of the unit groove is 10µm, the depth is 40µm, and the distance between the grooves is 10µm; then, referring to the drawn groove structure layout diagram, the silicon template is processed; the selected substrate is glass Substrate, and pre-clean it, that is, the glass substrate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com