Preparation method of star-shaped polyurethane elastomer toughened polylactic acid compound

A technology of polyurethane elastomer and polylactic acid, which is applied in the field of polylactic acid polymer compound and its preparation, achieves the effects of short production cycle, favorable for popularization and application, and easy-to-obtain and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A preparation method for a star-shaped polyurethane elastomer toughened polylactic acid compound, comprising the steps of:

[0060] Put the pre-dried polylactic acid, star polyurethane elastomer and diisocyanate together into the torque rheometer for blending and banburying, at a temperature of 170-210°C, a speed of 30-120 rpm, and a blending reaction of 3-20 Minutes to obtain the star-shaped polyurethane elastomer toughened polylactic acid compound;

[0061] The pre-dried raw materials are calculated in parts by mass, including 60-99 parts of polylactic acid, 1-40 parts of star-shaped polyurethane elastomer, and 0-10 parts of diisocyanate.

[0062] In practice, the polylactic acid is preferably 80-97 parts, the star polyurethane elastomer is preferably 3-20 parts, and the diisocyanate is preferably 0-5 parts, but not zero.

[0063] In the above method, the polylactic acid used is preferably commercially available technical grade polylactic acid, and the diisocyanate u...

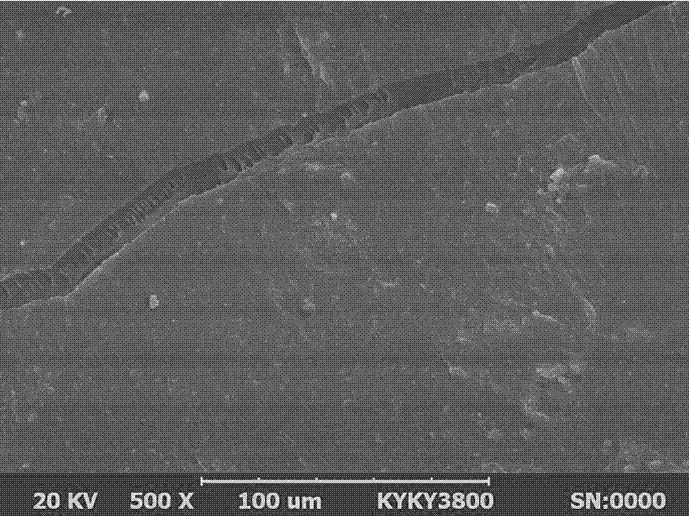

Embodiment 1

[0083] 95 parts of pre-dried polylactic acid and 5 parts of star-shaped polyurethane elastomer were added together into a torque rheometer for blending and banburying. At a temperature of 170 ° C and a speed of 30 rpm, the blending reaction was carried out for 3 minutes.

[0084] The synthesis (bulk prepolymerization method) of used star-shaped polyurethane elastomer: in there-necked flask, add number-average molecular weight is 2000 polypropylene glycol 191 parts, the polypropylene oxide ether triol 0.9 part of number-average molecular weight 300 and diphenylmethane 75 parts of diisocyanate were slowly heated to 70°C and stirred for 3 hours to make a prepolymer. Then control the prepolymer at 70-75°C, add 18 parts of butanediol under stirring, pour the solution into the prepared mold when it is viscous, and mold it at 120°C for 40 minutes when it gels. Finally, the obtained sample was placed in an oven at 110°C for post-curing for 20 hours. The composite is tested by injecti...

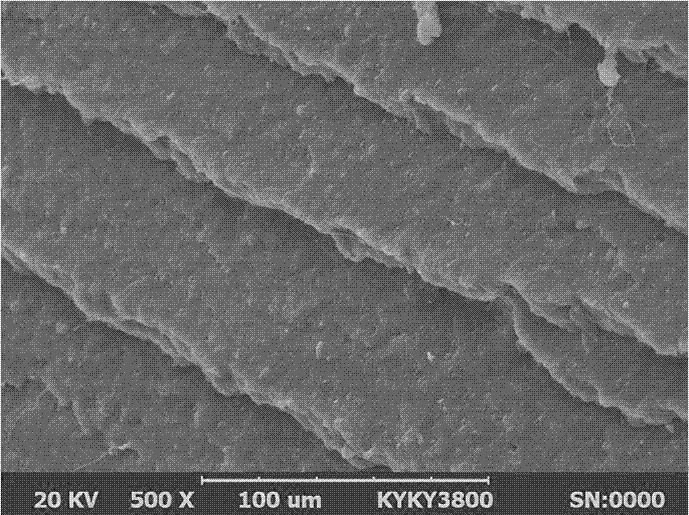

Embodiment 2

[0086] Add 90 parts of pre-dried polylactic acid and 10 parts of star-shaped polyurethane elastomer together into a torque rheometer for blending and banburying. At a temperature of 180 ° C and a speed of 40 rpm, the blending reaction is carried out for 5 minutes.

[0087] The synthesis (bulk prepolymerization method) of used star-shaped polyurethane elastomer: in there-necked flask, add number-average molecular weight is 2000 polypropylene glycol 191 parts, the polypropylene oxide ether triol 0.9 part of number-average molecular weight 300 and diphenylmethane 75 parts of diisocyanate were slowly heated to 70°C and stirred for 3 hours to make a prepolymer. Then control the prepolymer at 70-75°C, add 18 parts of butanediol under stirring, pour the solution into the prepared mold when it is viscous, and mold it at 120°C for 40 minutes when it gels. Finally, the obtained sample was placed in an oven at 110°C for post-curing for 20 hours. The composite is tested by injection mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com