High-temperature slag dry method cooling and pelleting waste heat recycling system and method

A waste heat recovery system and dry cooling technology, applied in the direction of recycling technology, etc., can solve the problems of high temperature equipment loss, high temperature slag viscosity requirements, poor equipment durability, etc., achieve process clean production reduction, strengthen gas convection exchange Heat, to achieve the effect of cooling and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

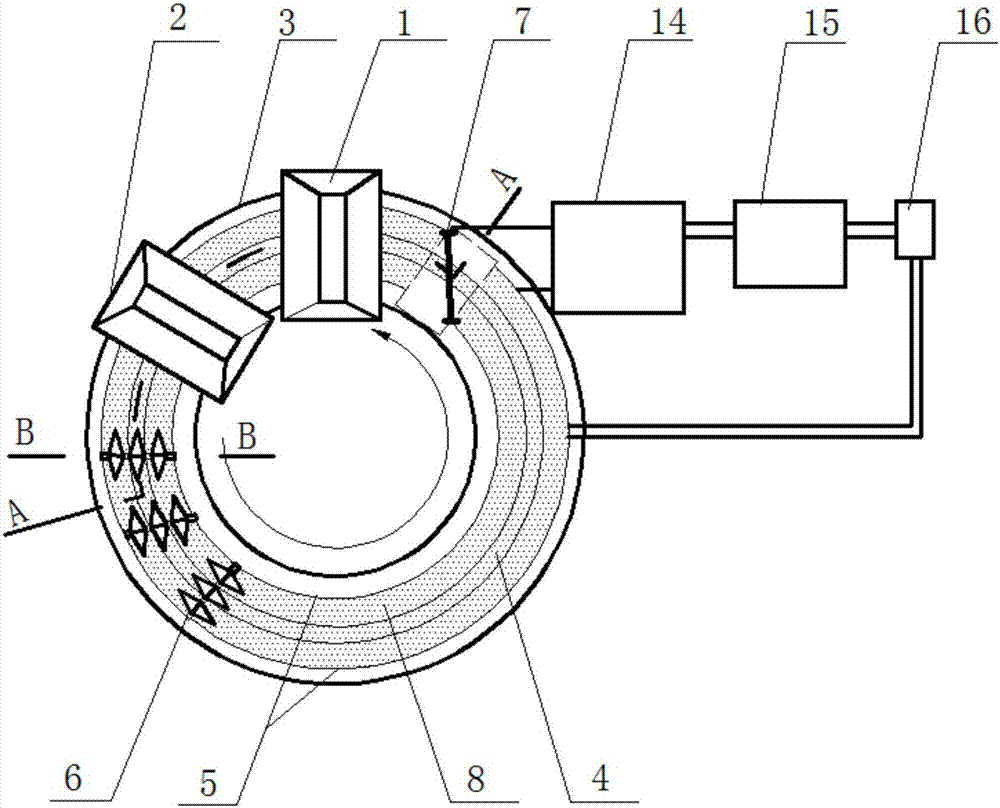

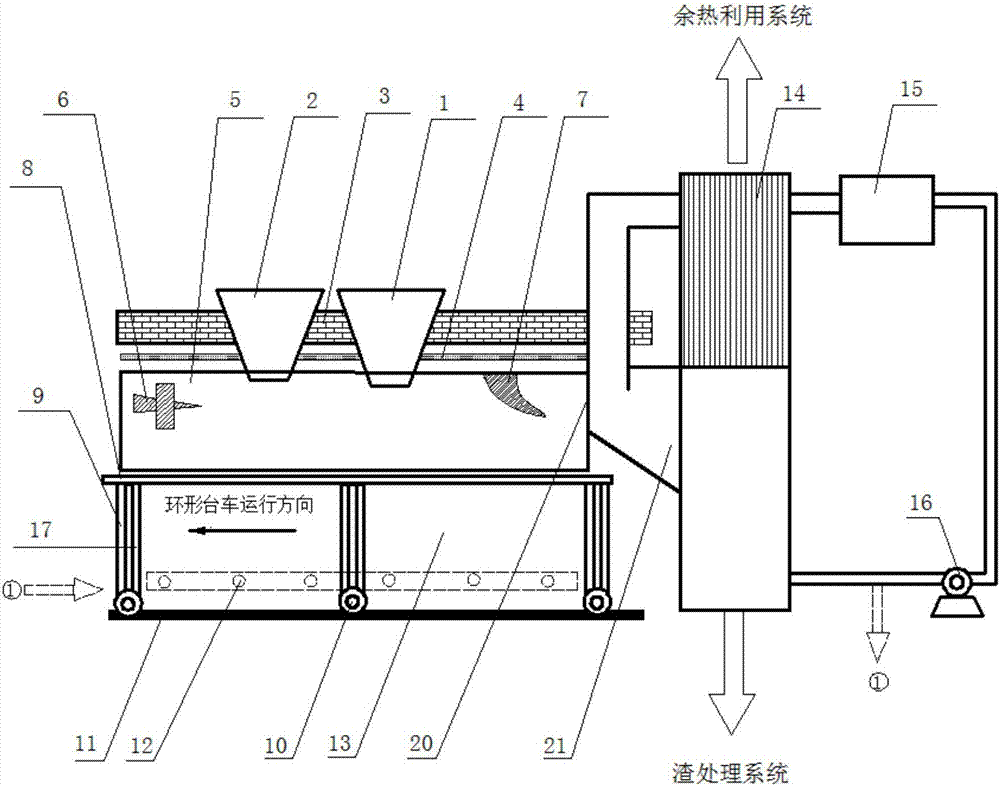

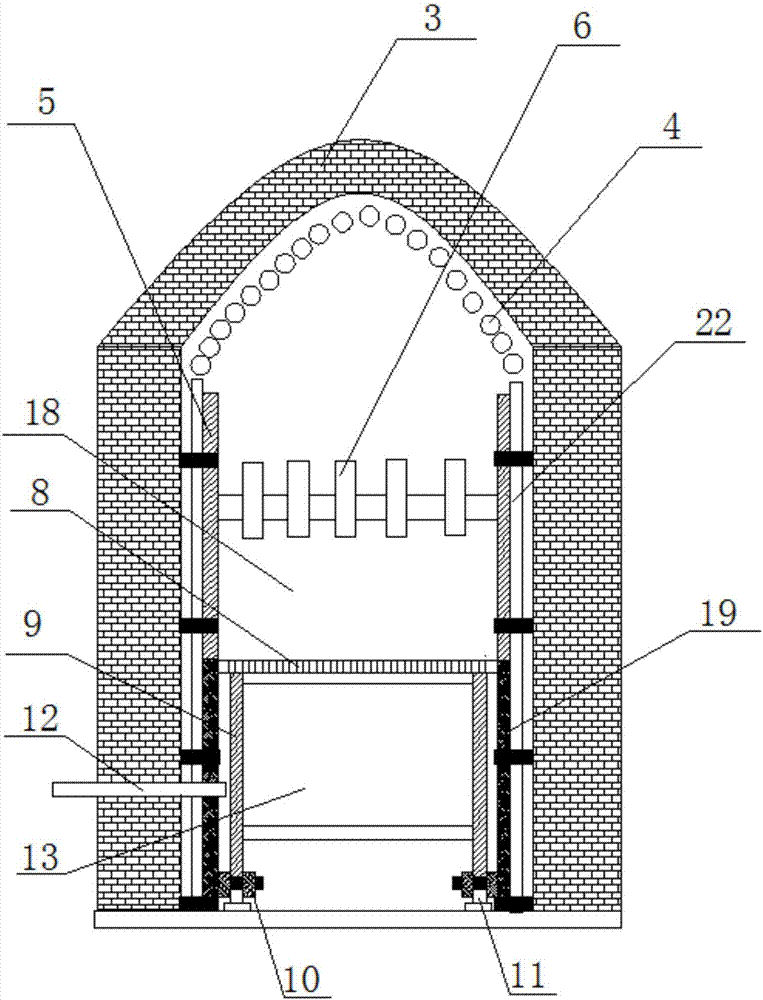

[0034] Such as Figure 1-3 As shown, a high-temperature slag dry cooling granulation waste heat recovery system in this embodiment includes: heat preservation tunnel 3, cold slag hopper 1, high-temperature slag hopper 2, water-cooled pipe 4, material blocking plate 5, plow slag Device 6, slag scraper 7, trolley track 11, air inlet pipe 12, cold air chamber 13, heat exchanger 14, dust collector 15, circulating fan 16, ring trolley 17, material storage tank 18, cold air chamber side plate 19 , slag outlet 20, chute 21 and pillar 22; the heat preservation tunnel 3 is an arch ring tunnel formed by a steel structure support frame on the inner layer and an outer layer made of refractory bricks. The lower end is fixed on the ground, and the heat preservation tunnel 3. The top is arched, and several water-cooling pipes 4 are arranged under the bottom of the ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com