Lithium ion capacitor graphene composite positive plate manufacturing method

A lithium ion and positive electrode technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of complex process and difficult manufacturing process, simplify the preparation process, achieve energy density and high power density, The effect of high energy density and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

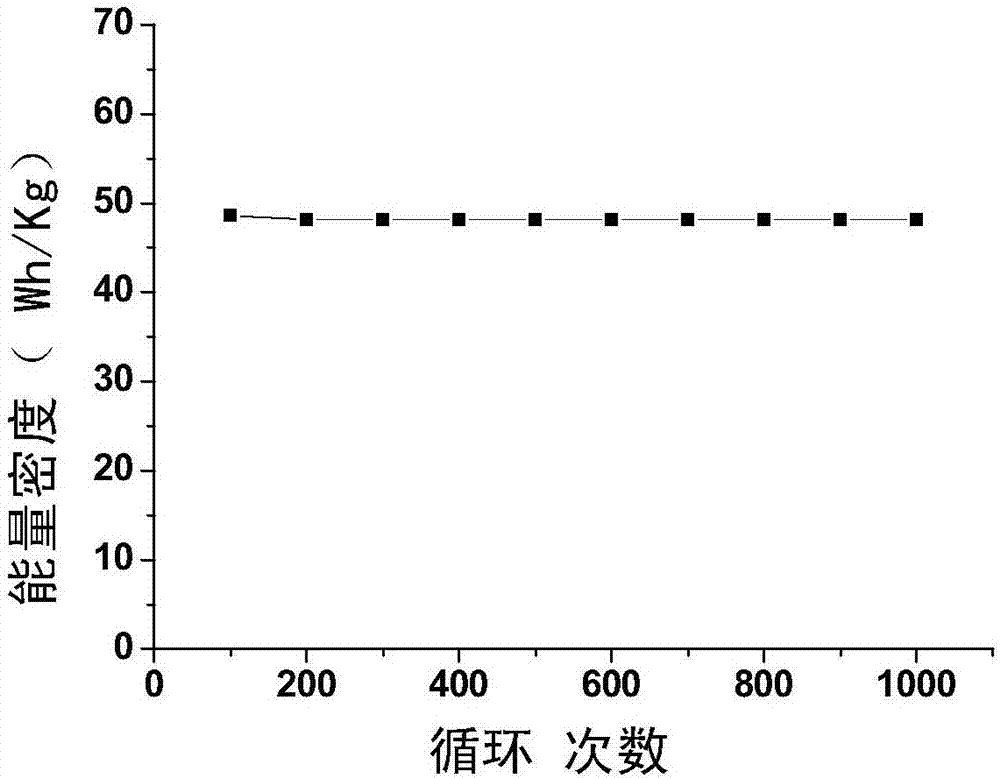

Examples

Embodiment 1

[0020] (1) Will Li 2 CO 3 and MoO 3 Mix according to the molar ratio of 1:1, mix evenly and put it in a muffle furnace for 3 hours at 500°C to react, and after the reaction, Li 2 MoO 4 .

[0021] (2) will get Li 2 MoO 4 Put it into a muffle furnace protected by a hydrogen-nitrogen mixture with a volume concentration of 5% hydrogen and react at 500 ° C for 5 hours. After the reaction, Li 2 MoO 3 Material.

[0022] (3) Set the specific surface area to 800m 2 The graphene material of / g joins in the NMP and forms 1g / L graphene suspension;

[0023] (4) Li 2 MoO 3 After the material was ball milled for 30 minutes, it was added to the obtained graphene suspension at a mass ratio of 50:1, and the graphene composite Li was obtained after suction filtration and evaporation of the solution. 2 MoO 3 material electrodes.

[0024] (5) Add graphite negative electrode material, conductive agent Ketjen black, and binder PVDF into NMP in a mass ratio of 90:5:5 to form a slurry, t...

Embodiment 2

[0027] (1) Will Li 2 CO 3 and MoO 3 Mix according to the molar ratio of 2:1, mix evenly and put it into the muffle furnace for 8 hours at 700°C to react. After the reaction, Li 2 MoO 4 .

[0028] (2) will get Li 2 MoO 4 Put it into a muffle furnace protected by a hydrogen-nitrogen mixed gas atmosphere with a volume concentration of 5% hydrogen at 900 ° C for 10 hours. After the reaction, Li 2 MoO 3 Material.

[0029] (3) Set the specific surface area to 1500m 2 The graphene material of / g joins in the NMP and forms 20g / L graphene suspension;

[0030] (4) Li 2 MoO 3 After the material was ball milled for 60 minutes, it was added to the obtained graphene suspension at a mass ratio of 5:1, and the graphene composite Li was obtained after suction filtration and evaporation of the solution. 2 MoO 3 material electrodes.

[0031] (5) Add hard carbon negative electrode material, conductive agent Ketjen black, and binder PVDF into NMP in a mass ratio of 90:5:5 to form a s...

Embodiment 3

[0034] (1) Will Li 2CO 3 and MoO 3 Mix according to the molar ratio of 1.3:1, mix evenly and put it into the muffle furnace for 7 hours at 600°C to react, and after the reaction, Li 2 MoO 4 .

[0035] (2) will get Li 2 MoO 4 Put it into a muffle furnace protected by a hydrogen-nitrogen mixture with a volume concentration of 5% hydrogen at 700 ° C for 8 hours, and obtain Li after the reaction is complete. 2 MoO 3 Material.

[0036] (3) Set the specific surface area to 1200m 2 The graphene material of / g joins in the NMP and forms 10g / L graphene suspension;

[0037] (4) Li 2 MoO 3 After the material was ball milled for 40 minutes, it was added to the obtained graphene suspension at a mass ratio of 25:1, and the graphene composite Li was obtained after suction filtration and evaporation of the solution. 2 MoO 3 material electrodes.

[0038] (5) Add graphite negative electrode material, conductive agent Ketjen black, and binder PVDF into NMP in a mass ratio of 90:5:5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com