InAs/AlSb HEMT and MOS-HEMT device manufacturing methods

A device and deposition technology, applied in the field of microelectronics, can solve problems such as device gate leakage, achieve the effect of reducing series resistance and gate current leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

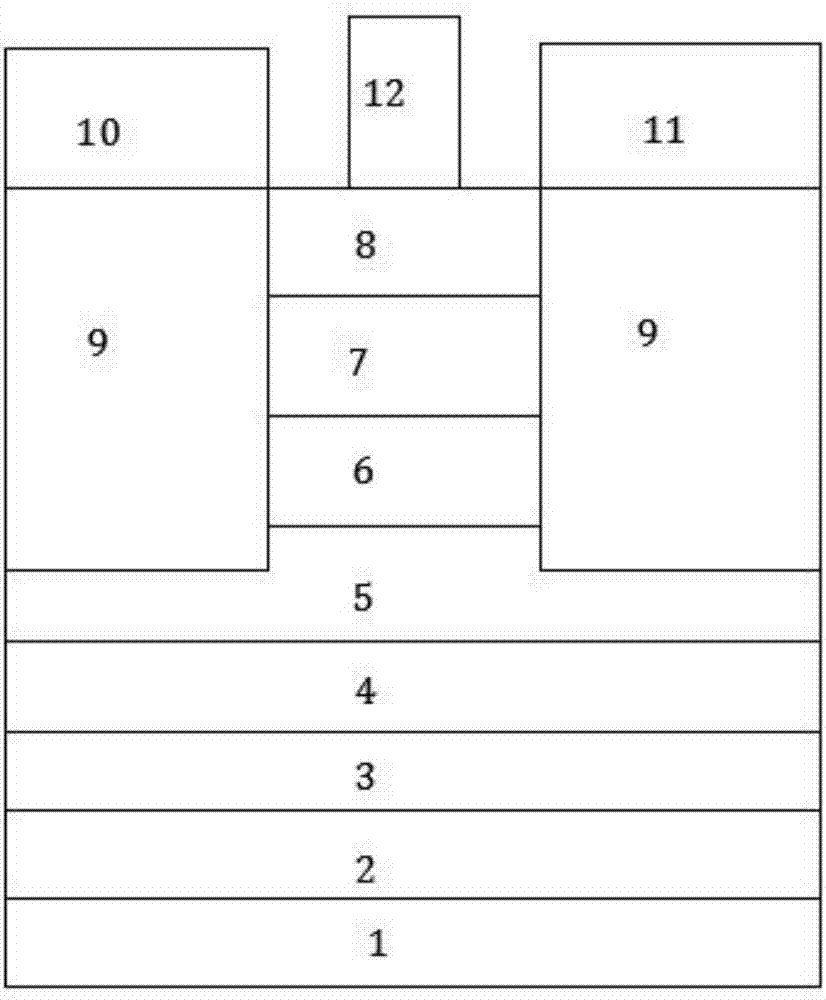

[0081] The InAs / AlSb HEMT device prepared in this embodiment uses GaAs as the substrate, the buffer layer 2 is AlGaSb, and the doped layer 6 is doped with a Si concentration of 4*10 19 cm -3 InAs layer. Concrete preparation process is as follows:

[0082] Step 1, epitaxial material growth: Using MBE process, grow buffer layer 2 (buffer layer 2 is AlGaSb), AlSb lower barrier layer 3, InAs channel layer 4, AlSb isolation layer 5, InAs doped Layer 6, AlSb upper barrier layer 7, InAlAs hole blocking layer 8;

[0083] Step 2. Countertop isolation:

[0084] (a) cleaning the epitaxially grown InAs / AlSb material, and then blowing it dry with nitrogen;

[0085] (b) Perform photolithography and etching on the cleaned InAs / AlSb material to complete the mesa isolation of the epitaxial material;

[0086] Step 3. Preparation of ohmic contacts:

[0087] (a) Clean the InAs / AlSb material after the table isolation, and then dry it with nitrogen;

[0088] (b) performing photolithography o...

Embodiment 2

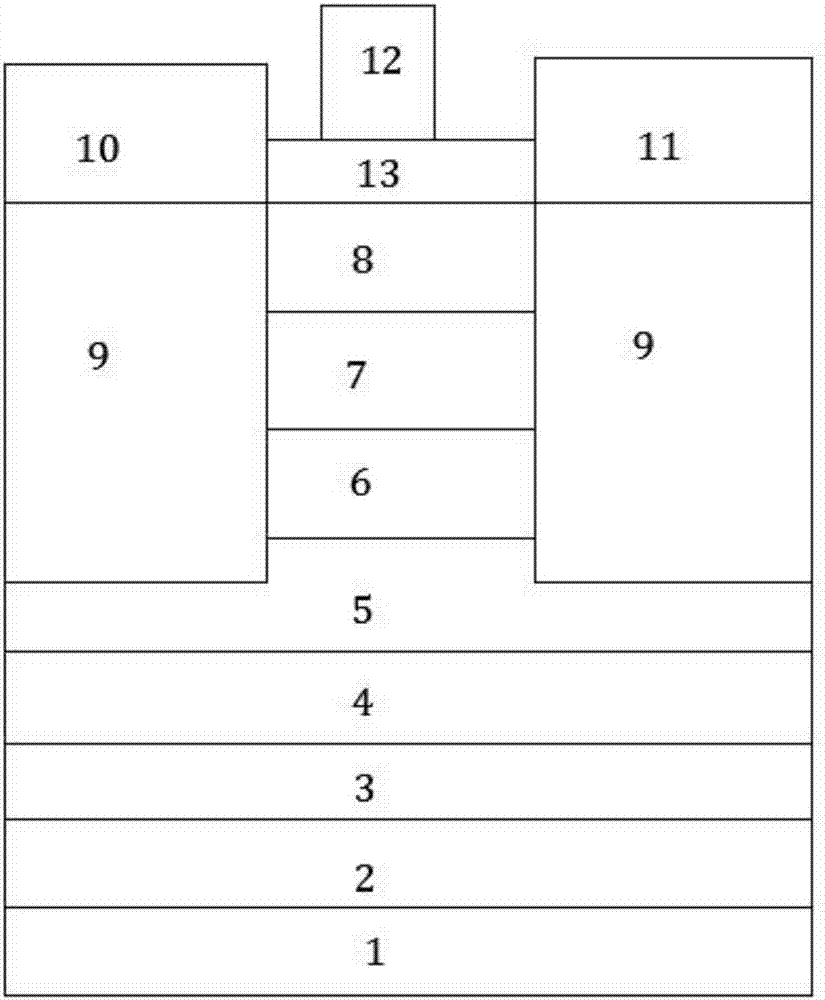

[0110] The InAs / AlSb MOS-HEMT device prepared in this embodiment uses GaAs as the substrate, the buffer layer 2 is AlGaSb, and the doped layer 6 is doped with a Si concentration of 4*10 19 cm -3 InAs layer, dielectric layer 13 is HfO 2 . Concrete preparation process is as follows:

[0111] 1) Epitaxial material growth: Using MBEMOCVD process, grow buffer layer 2 (buffer layer 2 is AlGaSb), AlSb lower barrier layer 3, InAs channel layer 4, AlSb isolation layer 5, doped layer 6 on substrate 1 in sequence , AlSb upper potential barrier layer 7, InAlAs hole blocking layer 8;

[0112] 2) Countertop isolation:

[0113] (a) cleaning the epitaxially grown InAs / AlSb material, and then blowing it dry with nitrogen;

[0114] (b) Photolithography and etching are performed on the cleaned InAs / AlSb material to complete the mesa isolation of the epitaxial material.

[0115] 3) Preparation of ohmic contacts:

[0116] (a) Clean the InAs / AlSb material after the table isolation, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com