Green method for producing tetrapropylammonium hydroxide by using membrane technique

A technology of tetrapropylammonium hydroxide and tetrapropylammonium bromide, which is applied in the field of green environmental protection, can solve the problems of tetrapropylammonium hydroxide solution pollution, cations entering the alkali chamber, etc., and achieve short production cycle and high conversion efficiency , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

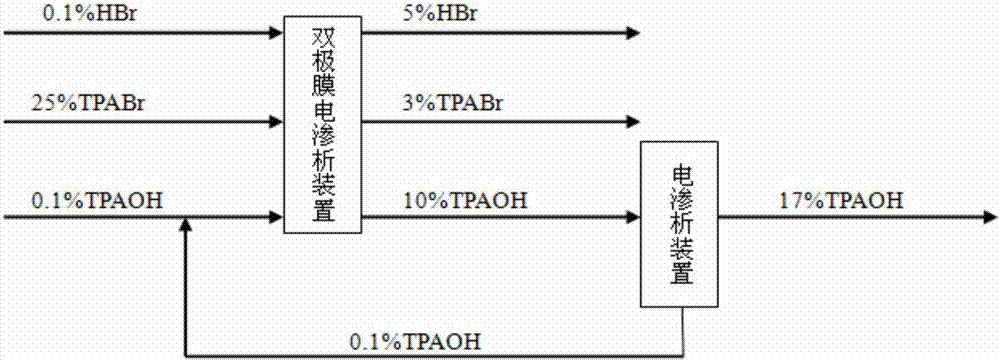

[0021] Such as figure 1 As shown, after the 25% tetrapropylammonium bromide solution is pretreated by a security filter, etc., and then passed through a bipolar membrane electrodialysis device, about 10% of tetrapropylammonium hydroxide and about 5% of hydrobromic acid are obtained. The tetrapropylammonium hydroxide is further concentrated to more than 17% by electrodialysis, and the desalination liquid produced in the electrodialysis desalination chamber is reused as the receiving liquid in the alkali chamber of the bipolar membrane device for the next batch of liquid treatment.

[0022] Specific steps are as follows:

[0023] In the first step, the prepared 25% tetrapropylammonium bromide solution is subjected to pretreatment such as sand filtration and microfiltration to remove impurities such as suspended solids in the feed liquid.

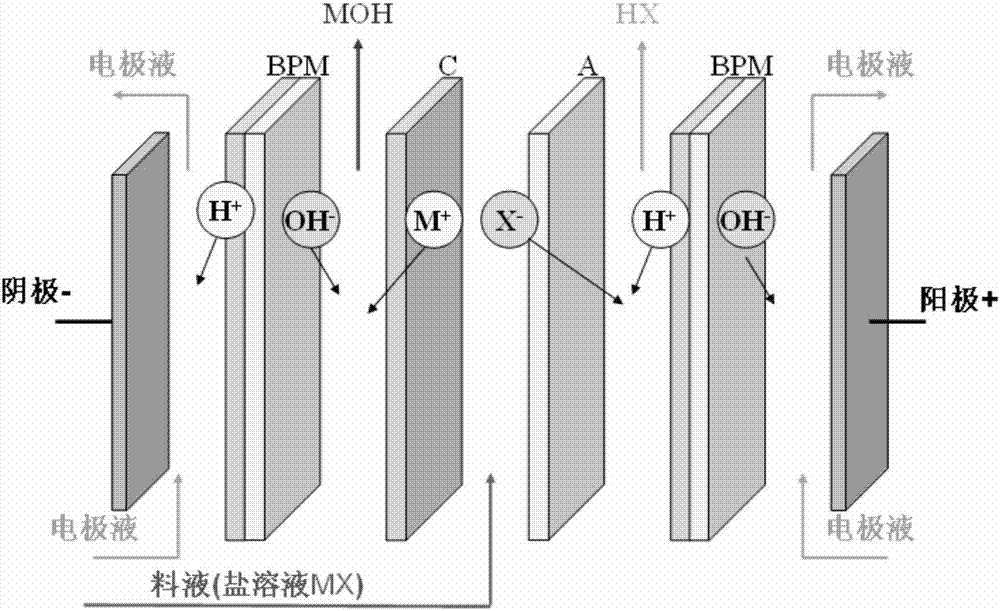

[0024] In the second step, the feed liquid after impurity removal enters the bipolar membrane electrodialysis device for treatment, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com