A non-pickling and chrome-free tanning process based on multi-metal complex tanning agents

A technology with tanning agents and multi-metals, applied in the field of non-pickling and chrome-free tanning process, can solve the problems of inability to effectively realize clean production, difficult production and application, deepening of leather color, etc., to increase shrinkage temperature, promote penetration and combination , the effect of increasing the shrinkage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

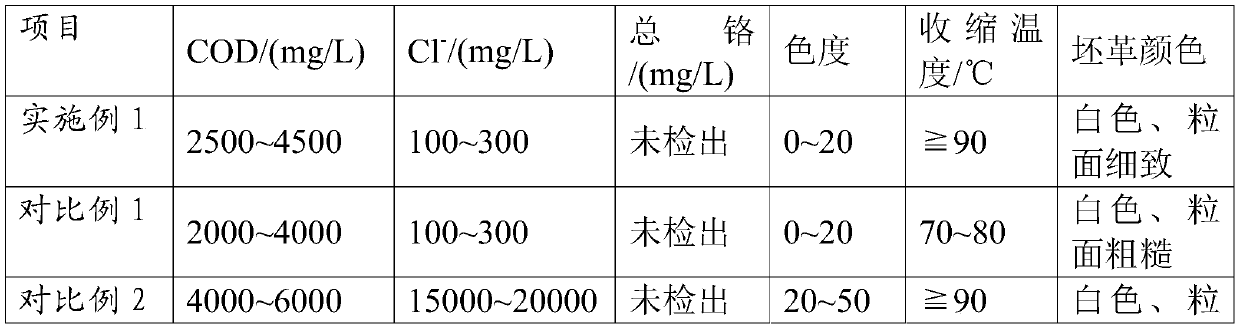

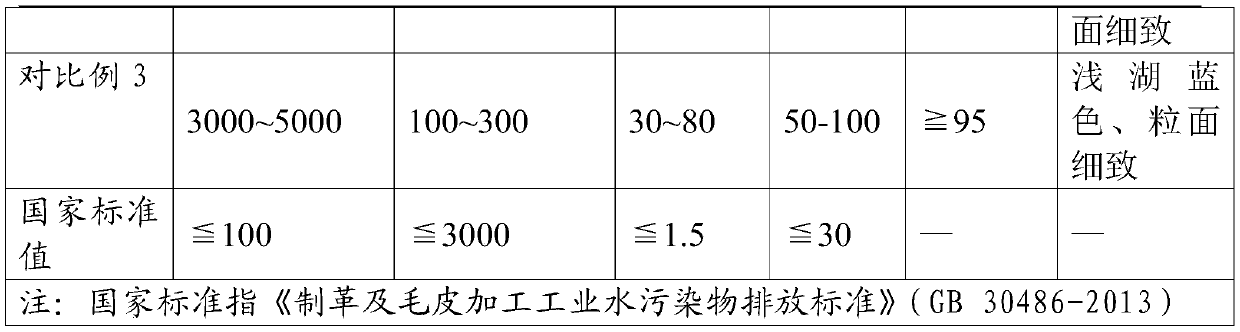

Examples

Embodiment 1

[0025] A chromium-free and acid-free tanning process based on a multi-metal compound tanning agent includes the following steps in sequence:

[0026] Step 1. Prepare the softened bare skin, weigh the weight of the softened bare skin, and determine the weight of the reagent used in the subsequent processing steps by the weight;

[0027] Step 2. Pretreatment of softened bare skin (the amount of reagent is calculated as the percentage of the weight of softened bare skin): add 50% water into the drum, the temperature inside the drum is 22-26℃, rotate for 20 minutes, add 3 diluted with water 1:5 % Pretreatment agent (TANINTAN BOV of Mingzhong Chemical Co., Ltd.), rotate for 60 minutes;

[0028] Step 3. Tanning (the amount of reagent is calculated as the percentage of the weight of the softened bare skin): In step 2, add 40% of the multi-metal complex tanning agent (Zirconium-aluminum-titanium complex tanning agent of Jinkun Chemical Co., Ltd.), 1% Resistant to electrolyte oil (GHL of Daw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com