Application of attapulgite/sodium alginate organic-inorganic hybrid material in modifying cotton fabric and cotton fabric finishing method

A technology of sodium alginate and hybrid material, applied in the field of materials, can solve the problems of easy breeding of bacteria and poor anti-ultraviolet performance, and achieve the effect of improving anti-ultraviolet performance, mechanical performance and reducing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] An attapulgite / sodium alginate organic-inorganic hybrid material provided in this example is prepared through the following steps: it is prepared in this way:

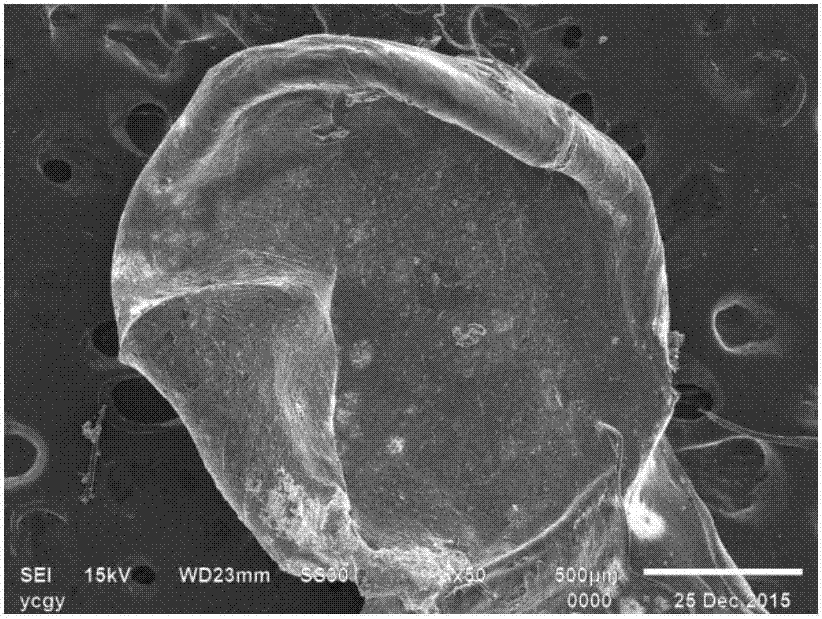

[0058] When the volume of the solution is 1L, prepare 25g / L sodium alginate solution and 3g / L attapulgite solution, stir 1.6L sodium alginate solution and 0.4L attapulgite solution in a water bath at 50°C, and compound The material was dropped into the calcium chloride solution at a uniform speed with needles of different apertures, and was continuously stirred and solidified for 0.5 hours to prepare microcapsules of attapulgite / sodium alginate organic-inorganic hybrid material.

Embodiment 2

[0060] An attapulgite / sodium alginate organic-inorganic hybrid material provided in this example is prepared through the following steps: it is prepared in this way:

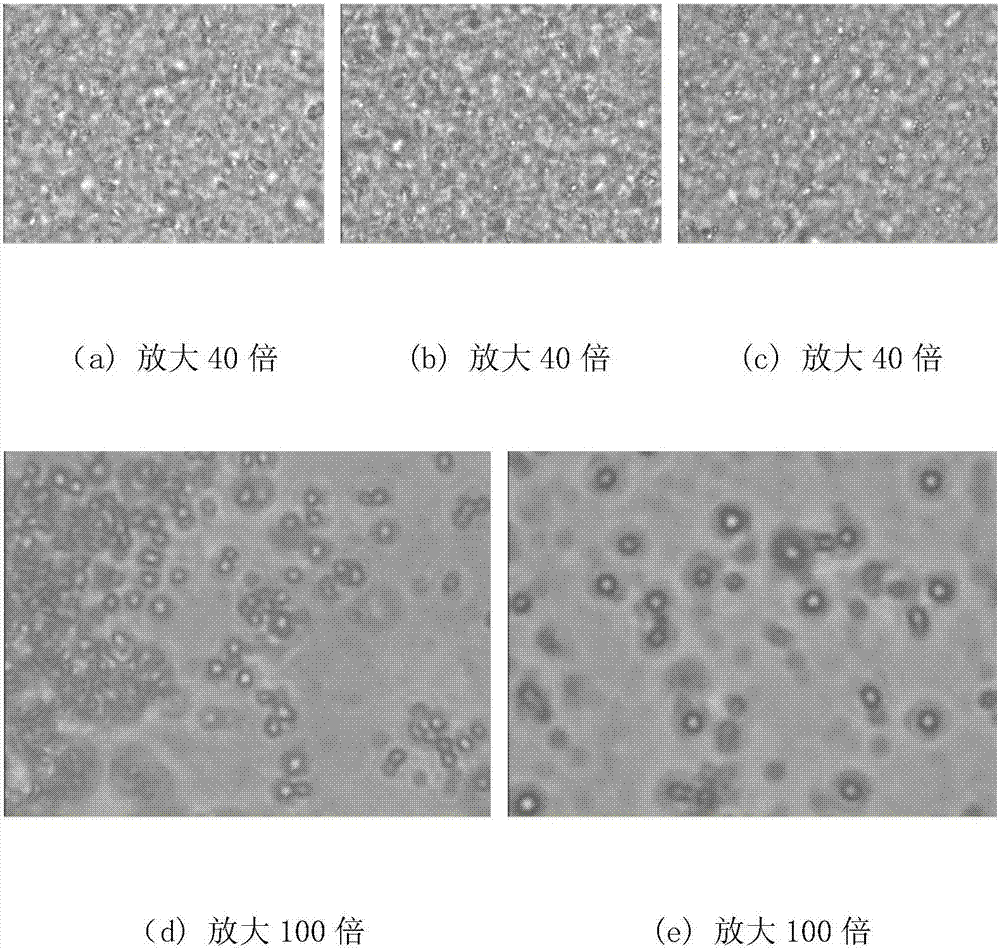

[0061] Use sodium alginate and 7g / L attapulgite solutions with concentrations of 5g / L, 7.5g / L, 10g / L, 15g / L, 25g / L and attapulgite solutions at 50°C to fully stir, and add CaCl 2 As the curing agent, the compound was dropped into the calcium chloride solution at a constant speed with needles of different apertures, and continuously stirred and solidified for 1.5 hours to obtain microcapsules of attapulgite / sodium alginate organic-inorganic hybrid materials, respectively marked as a , b, c, d, e.

Embodiment 3

[0063] An attapulgite / sodium alginate organic-inorganic hybrid material provided in this example is prepared through the following steps: it is prepared in this way:

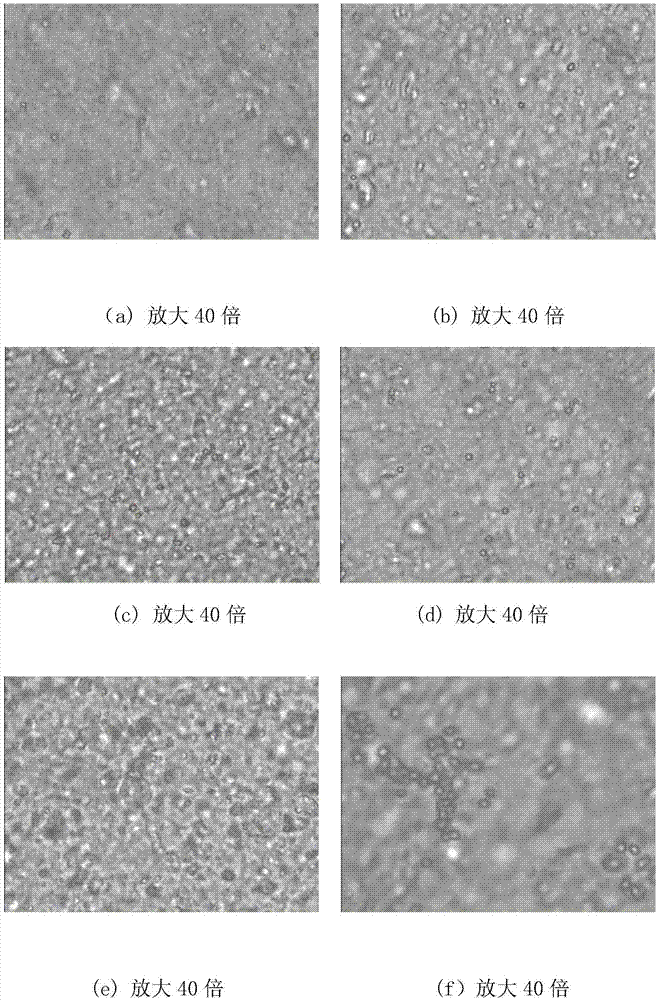

[0064] Attapulgite with a concentration of 2g / L, 5g / L, 10g / L, 15g / L, 20g / L, and 25g / L and sodium alginate solution of 20g / L were used to stir fully in a water bath at 60°C, and then mixed with CaCl 2 As a curing agent, the compound was dropped into the calcium chloride solution at a constant speed with needles of different apertures, and continuously stirred and solidified for 2.5 hours to obtain microcapsules of attapulgite / sodium alginate organic-inorganic hybrid materials, respectively marked as a , b, c, d, e, f.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com