Flux for lead-free solder, and lead-free solder paste

A brazing and flux technology, applied in the field of lead-free soldering flux and lead-free soldering paste, can solve the problems of reduced preservation stability of flux residue insulation resistive soldering paste, etc., and achieve excellent screen printing adaptability, Avoid the effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

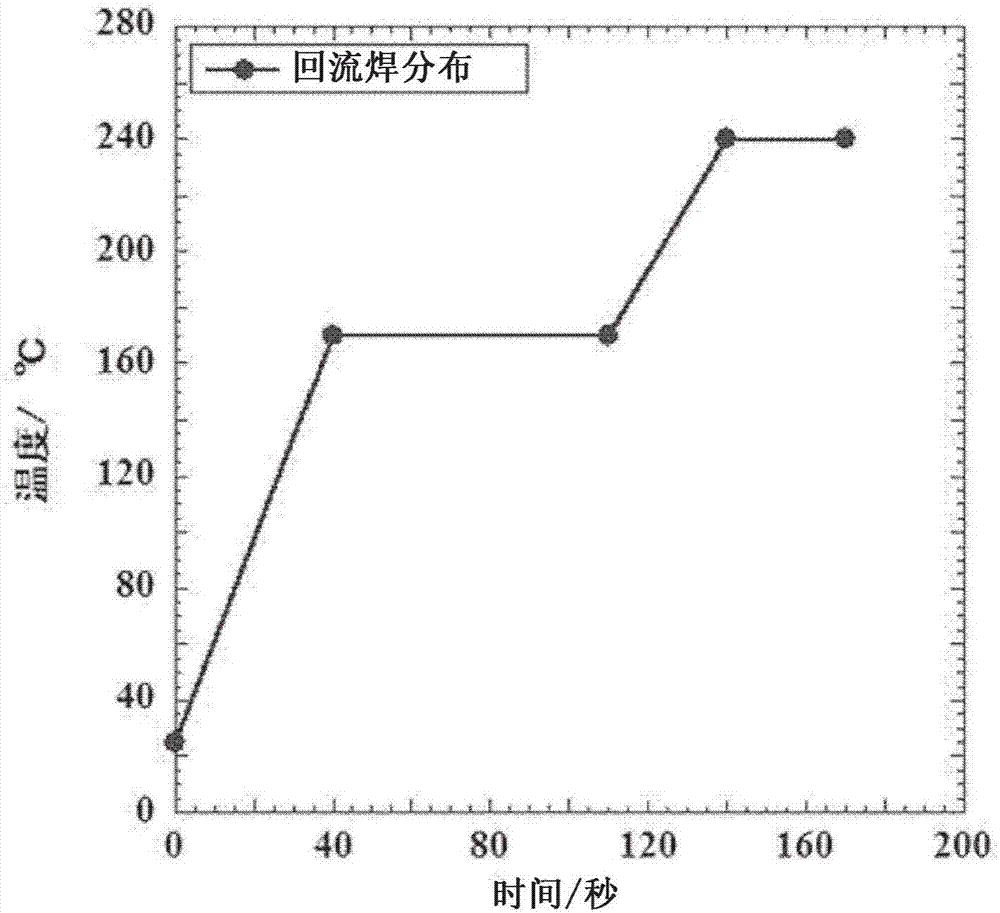

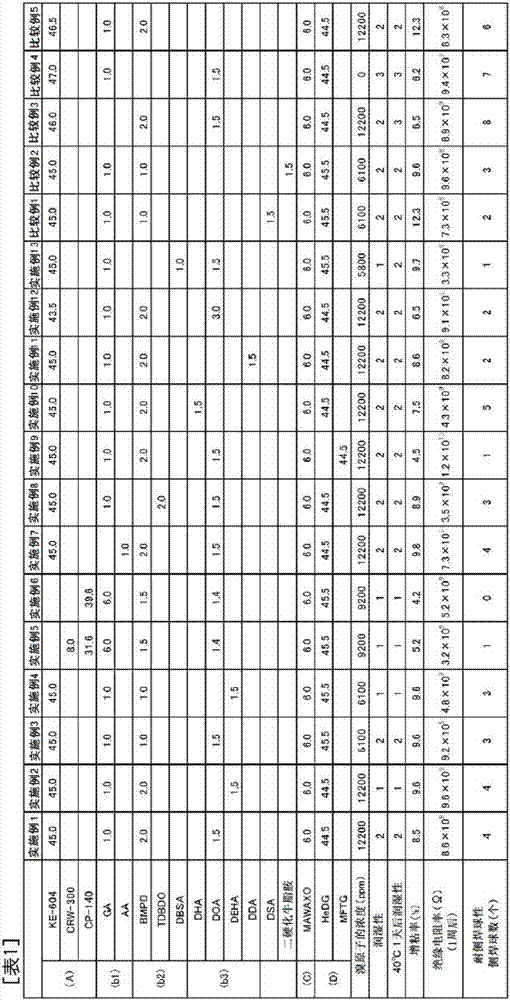

[0067] A hydrogenated product of acrylated rosin (trade name "KE-604", manufactured by Arakawa Chemical Industry Co., Ltd.) 45% by weight, glutaric acid (manufactured by Tokyo Chemical Industry Co., Ltd.) 1% by weight, an amide-based thixotropic agent (product name "MA-WAX-O", 12-hydroxystearic acid ethylene bisamide, manufactured by KF Trading Co., Ltd.) 6% by weight, 2,2-bis(bromomethyl)-1,3-propanediol 2% by weight %, 1.5% by weight of dioctylamine and 44.5% by weight of hexanediol were mixed and melted under heating to prepare a flux for lead-free soldering.

[0068] Next, 0.1 g of this flux was collected and burned at 1250°C in a commercially available combustion device (product name "Automatic Sample Combustion Device AQF-100", manufactured by Mitsubishi Chemical Analitec Co., Ltd.). The gas is passed into purified water, thereby preparing a sample liquid. Next, this sample liquid was set in a commercially available ion chromatography device (product name "DX-500", manu...

Embodiment 2~13 and comparative example 1~5

[0070] Various fluxes were prepared in the same manner as in Example 1 except that the raw material composition shown in Table 1 was changed.

[0071] (Preparation of lead-free solder paste)

[0072]Commercially available lead-free solder powder (96.5Sn / 3Ag / 0.5Cu, manufactured by Mitsui Kinzoku Co., Ltd., particle size 20-38 μm, common product) and the flux of Example 1 were sequentially added to achieve 89% by weight and 11% by weight. The method is kneading in a softener to prepare solder paste. Also about the fluxes of Examples 2-13 and Comparative Examples 1-5, the solder paste was prepared by the method similar to Example 1.

[0073]

[0074] Using a screw viscometer (product name "PCU-205", coaxial double-layer cylindrical rotary type, manufactured by Malcom Co., Ltd.), the solder pastes of Examples 1 to 13 and Comparative Examples 1 to 5 were measured immediately after preparation. The viscosity of the solder paste and the viscosity after keeping the paste in a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com