Water-based pressure-sensitive adhesive compositions

A technology of composition, emulsion composition, applied in the direction of adhesive type, ester copolymer adhesive, adhesive, etc., can solve the problems of reduced importance, pollution, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0153] All parts, percentages, ratios, etc. in the examples are by weight unless otherwise indicated.

[0154] As used herein, the term "pph" means parts per hundred.

[0155] Table 1: Materials

[0156]

[0157]

[0158]

[0159]

[0160] Test Method 1: Measurement of Polymer Molecular Weight

[0161] The molecular weight distribution of the compounds was characterized using gel permeation chromatography (GPC). The GPC instrument was purchased from Waters Corporation (Waters Corporation, Milford, MA, USA) in Milford, Massachusetts, and it included a high-pressure liquid chromatography pump (model 1515HPLC), an autosampler (model 717), a UV detector ( Model 2487) and Refractive Index Detector (Model 2410). The chromatograph was equipped with two 5 micron PLgel MIXED-D columns obtained from Varian Inc. (Palo Alto, CA, USA).

[0162] Polymer solution samples were prepared by dissolving polymer or dried polymer samples in tetrahydrofuran at a concentration of ...

preparation example 1

[0195] Preparation Example 1 (PE-1)

[0196] A two-step process was used to prepare the polymers. In the first step of polymerization, a mixture consisting of 88 kg IBOA, and 2.72 kg acrylic acid (AA), and 90.8 g IRGANOX 1010, 381 g IOTG, 18.2 g MEHQ, and 1.8 grams of VAZO 52. The reactor was sealed and purged with nitrogen, then maintained under a nitrogen pressure of approximately 5 psig (34.5 kPa). The reaction mixture was heated to 60°C (140°F) and reacted adiabatically with a peak temperature of 127°C (260°F). When the reaction was complete, the mixture was cooled to below 50 °C.

[0197] In the second step, 10.9 grams of VAZO 52, 3.6 grams of VAZO 67, 5.4 grams of VAZO 88, 5.4 grams of LUPERSOL 101 and 7.3 grams of LUPERSOL 130 were added to the reaction product of the first step (initiator components dissolved in a small amount of ethyl acetate solution in ester). An additional 191 grams of IOTG was then added. The reactor was sealed and purged with nitrogen and...

preparation example 2

[0199] Preparation example 2 (PE-2)

[0200] In the first step of polymerization, 2 kg of a mixture consisting of 300 g of IOA, 1600 g of IBOA, and 100 g of AA, and 2 g of IRGANOX 1010, 50 g of IOTG, 0.4 grams of MEHQ, and 0.12 grams of VAZO 52. The reactor was sealed, purged of oxygen with nitrogen, and maintained under a nitrogen pressure of approximately 5 psig (approximately 34 kPa). In a first step the reaction mixture is heated to 60° C. and reacted adiabatically. The temperature peaked at 149°C. When the reaction was complete, the mixture was cooled to below 50 °C.

[0201] The various initiators (0.36 g VAZO 52, 0.08 g VAZO 67, 0.12 g VAZO 88, 0.12 g LUPERSOL 101, and 0.16 g LUPERSOL 130) dissolved in a minimum amount of ethyl acetate were then added to the reaction product in the first step ) solution and 25 grams of IOTG. The reactor was sealed and purged of oxygen with nitrogen, then maintained under a nitrogen pressure of 5 psig (approximately 34 kPa). The ...

PUM

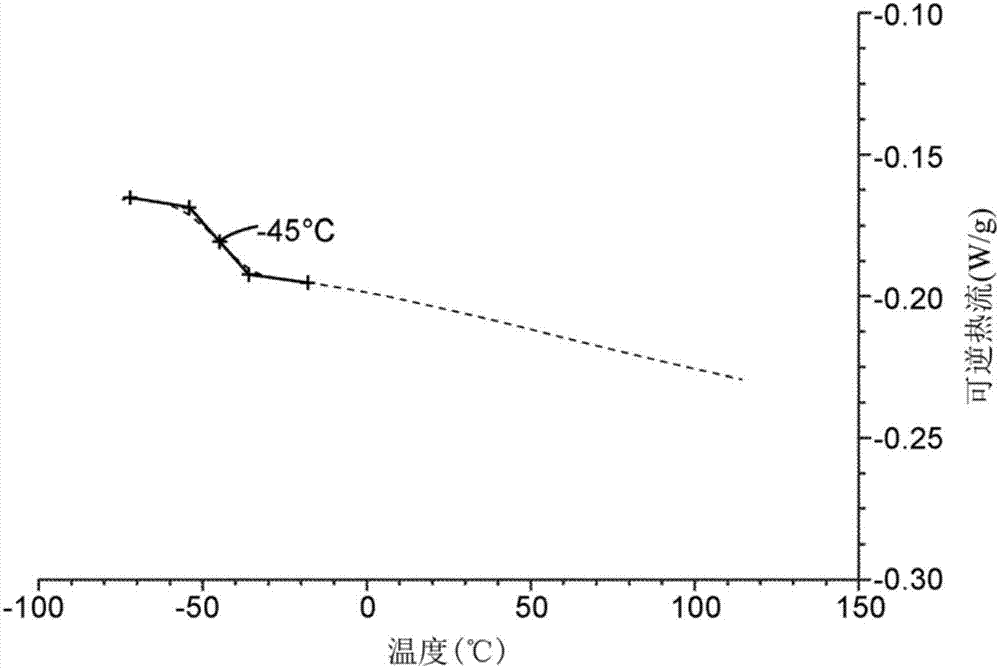

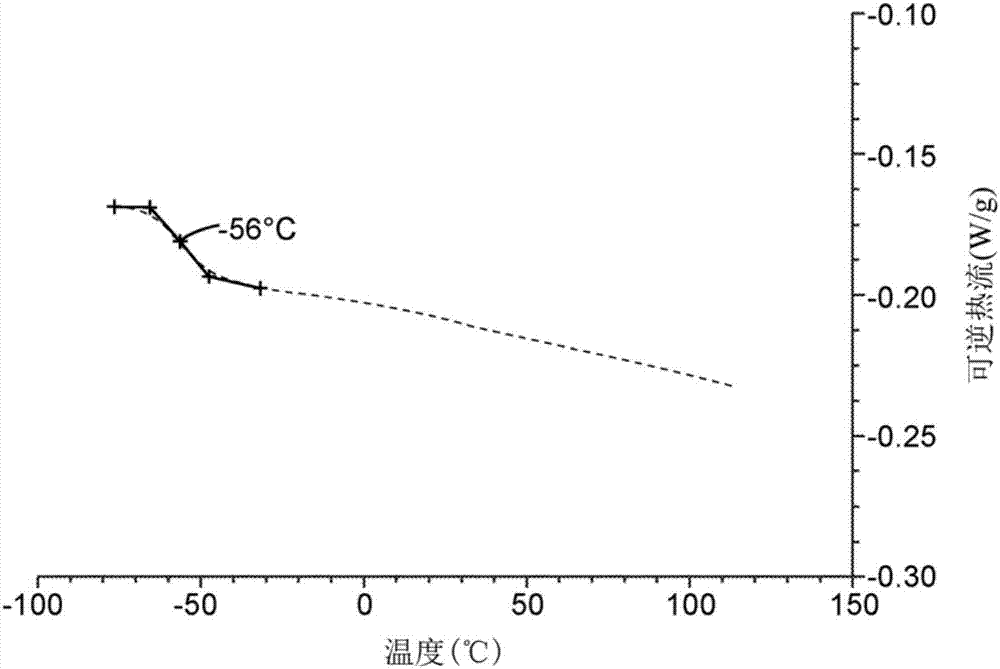

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com