Preparation methods for CQDs/TNS composite photocatalyst and SiQDs/TNS composite photocatalyst

A technology of catalyst and composite light, which is applied in the field of photocatalysis, can solve the problems of catalyst separation and recovery and the practicality of recyclable performance constraints, and achieve the effect of stable composite photocatalyst, good degradation effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] CQDs / TNS mass ratio is 2.5%

[0021] (1) using gelatin as a carbon source, hydrothermal treatment to obtain a carbon quantum dot solution;

[0022] (2) The initially obtained CQDs solution is modified by polyethylene glycol reflux to obtain uniformly dispersed carbon quantum dots;

[0023] (3) adopt tetrabutyl titanate as titanium source, hydrothermal treatment obtains TNS;

[0024] (4) Mix CQDs and TNS in an ethanol solution with a mass ratio of 2.5%, adjust the pH to 3-4 with HCl, reflux for 5 hours, then wash and dry to obtain a CQDs / TNS composite photocatalyst.

Embodiment 2

[0026] CQDs / TNS mass 7.5%

[0027] (1) using gelatin as a carbon source, hydrothermal treatment to obtain a carbon quantum dot solution;

[0028] (2) The initially obtained CQDs solution is modified by polyethylene glycol reflux to obtain uniformly dispersed carbon quantum dots;

[0029] (3) adopt tetrabutyl titanate as titanium source, hydrothermal treatment obtains TNS;

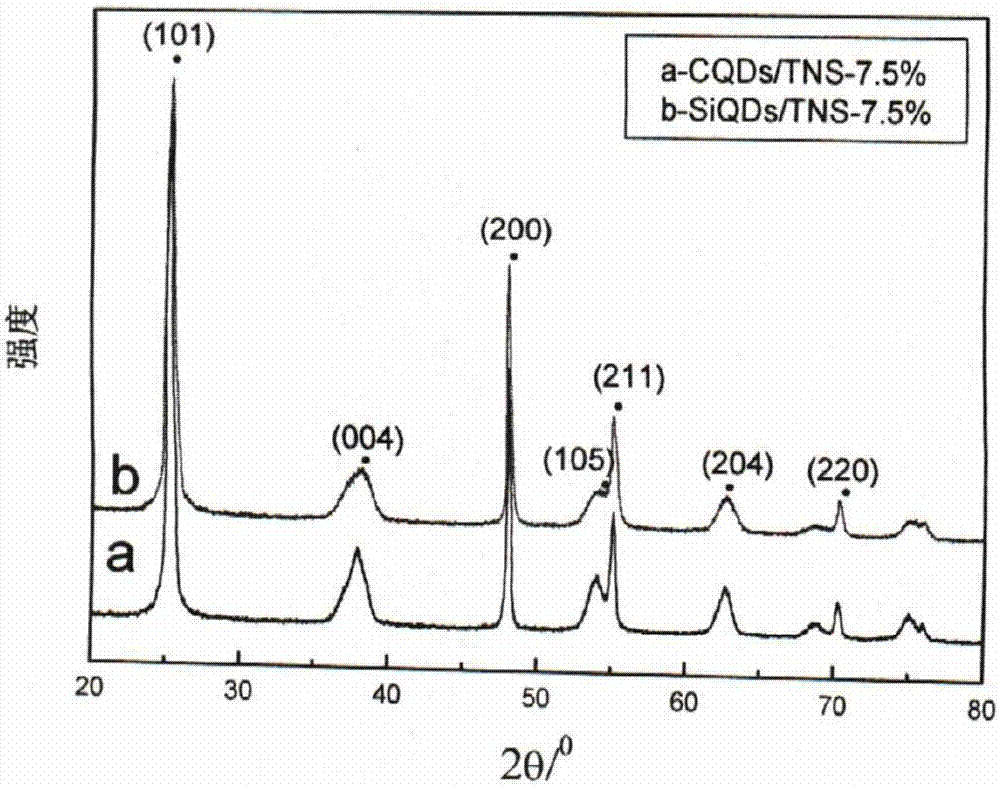

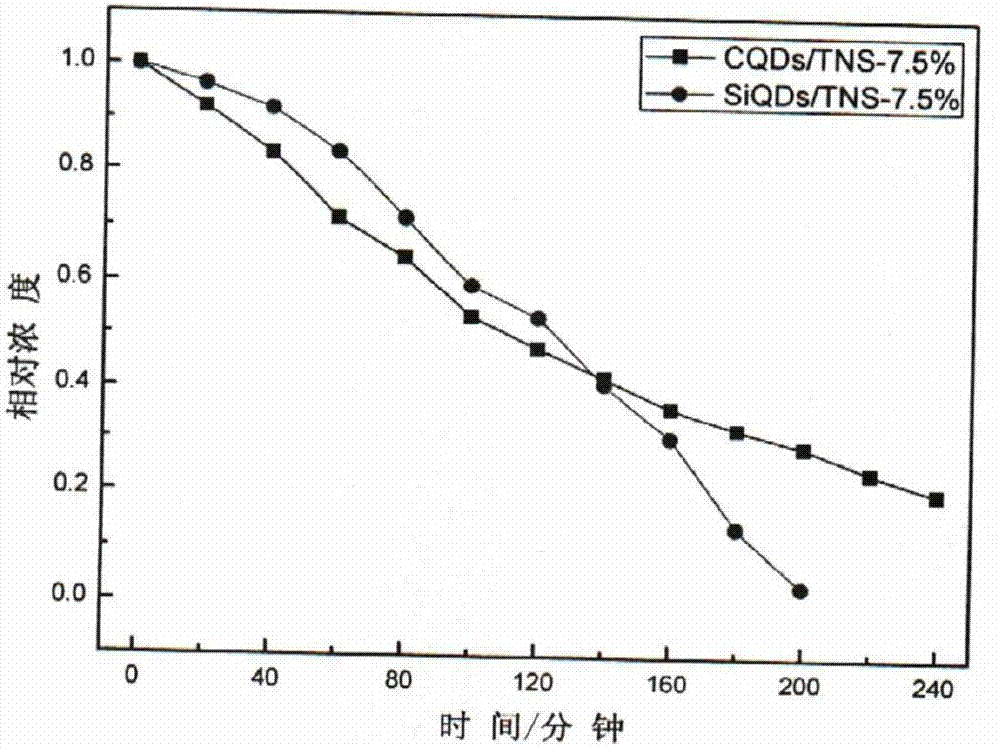

[0030] (4) Mix CQDs and TNS in an ethanol solution with a mass ratio of 7.5%, adjust the pH to 3-4 with HCl, reflux for 5 hours, then wash and dry to obtain a CQDs / TNS composite photocatalyst. Its XRD collection of illustrative plates and and photocatalytic activity curve are shown in the appendix of specification sheet figure 1 and figure 2 .

Embodiment 3

[0032] CQDs / TNS mass ratio is 12.5%

[0033] (1) using gelatin as a carbon source, hydrothermal treatment to obtain a carbon quantum dot solution;

[0034] (2) The initially obtained CQDs solution is modified by polyethylene glycol reflux to obtain uniformly dispersed carbon quantum dots;

[0035] (3) adopt tetrabutyl titanate as titanium source, hydrothermal treatment obtains TNS;

[0036] (4) Mix CQDs and TNS in an ethanol solution with a mass ratio of 12.5%, adjust the pH to 3-4 with HCl, reflux for 5 hours, then wash and dry to obtain a CQDs / TNS composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com