High-strength anti-aging warp knitting complex geotextile as well as preparation method of anti-aging layer thereof

A composite geotextile, high-strength technology, applied in the field of building materials, can solve the problems of easy wear, easy puncture of warp knitted composite geotextile, easy aging, etc. The effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

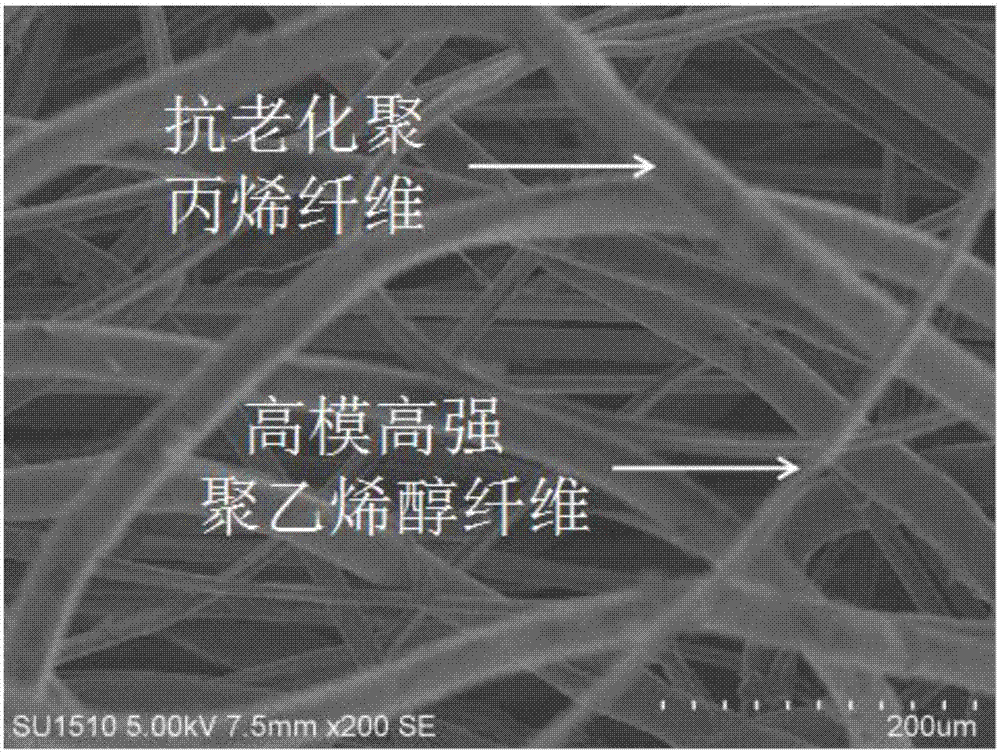

[0030] 1) The non-woven fabric layer is made of high-modulus and high-strength polyvinyl alcohol short fibers and anti-aging polypropylene short fibers. The mass-to-number ratio of the two raw materials is 3:7. prepared from thorns;

[0031] 2) The woven geotextile layer adopts the warp knitting process and is prepared from anti-aging polypropylene braided wires with a diameter of 0.1 mm, and the distance between two adjacent polypropylene braided wires is 2.0 cm.

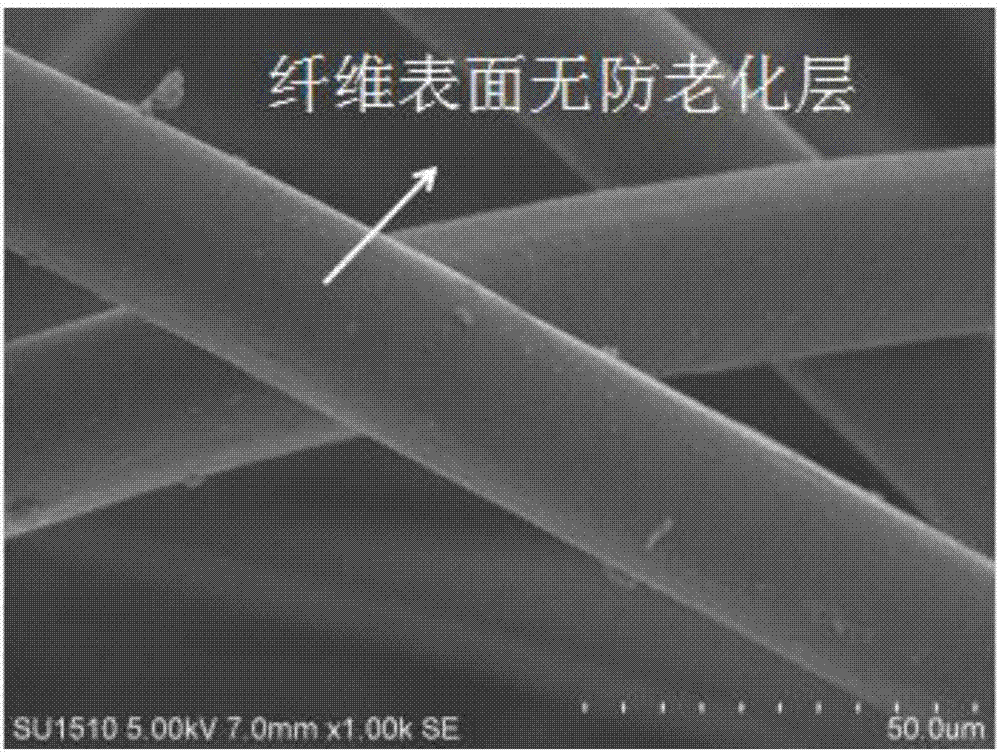

[0032] 3) The raw materials of the anti-aging layer are nano-silica and fluorocarbon acrylate, the mass-number ratio of nano-silica to fluorocarbon acrylate is 3:97, and the fluorocarbon acrylate refers to fluorocarbon acrylate lotion. First, put 3 parts of nano-silica into 97 parts of fluorocarbon acrylate emulsion, add 100 parts of deionized water at the same time, and stir at high speed to prepare a dispersed hybrid emulsion. Immerse the warp-knitted composite geotextile in the dispersed hybrid emulsion, take ...

Embodiment 2

[0034] The invention provides a high-strength anti-aging warp-knitted composite geotextile, the specific structure is as follows:

[0035] 1) The raw materials used in the non-woven fabric layer are high-modulus and high-strength polyvinyl alcohol short fibers and anti-aging polypropylene short fibers. The mass-to-number ratio of the two raw materials is 5:5. After opening, mixing, carding, and laying , prepared by acupuncture. ;

[0036] 2) The woven geotextile layer adopts the warp knitting process and is prepared from anti-aging polypropylene braided wires with a diameter of 0.3 mm, and the distance between two adjacent polypropylene braided wires is 1.6 cm.

[0037]3) The raw materials of the anti-aging layer are nano-silica and fluorocarbon acrylate, the mass-number ratio of nano-silica to fluorocarbon acrylate is 5:95, and the fluorocarbon acrylate refers to fluorocarbon acrylate lotion. First, put 5 parts of nano-silica into 95 parts of fluorocarbon acrylate emulsion...

Embodiment 3

[0039] The invention provides a high-strength anti-aging warp-knitted composite geotextile, the specific structure is as follows:

[0040] 1) The raw materials used in the non-woven fabric layer are high-modulus and high-strength polyvinyl alcohol short fibers and anti-aging polypropylene short fibers. The mass-to-number ratio of the two raw materials is 6:4. After opening, mixing, carding, and laying , prepared by acupuncture. ;

[0041] 2) The woven geotextile layer adopts the warp knitting process and is prepared from anti-aging polypropylene braided wires with a diameter of 0.3 mm, and the distance between two adjacent polypropylene braided wires is 1.3 cm.

[0042] 3) The raw materials of the anti-aging layer are nano-silica and fluorocarbon acrylate, the mass-number ratio of nano-silica to fluorocarbon acrylate is 7:93, and the fluorocarbon acrylate refers to fluorocarbon acrylate lotion. First, put 7 parts of nano-silica into 93 parts of fluorocarbon acrylate emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com