Composition for conditioning cadmium-polluted selenium-rich soil, and use method and use thereof

A technology of selenium-enriched soil and composition, which is applied in the field of soil pollution control, can solve the problems of reducing the effectiveness of heavy metals, increasing the cost and workload of soil remediation, and limitations, and achieves the goals of low remediation cost, increased organic matter content, and reduced remediation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

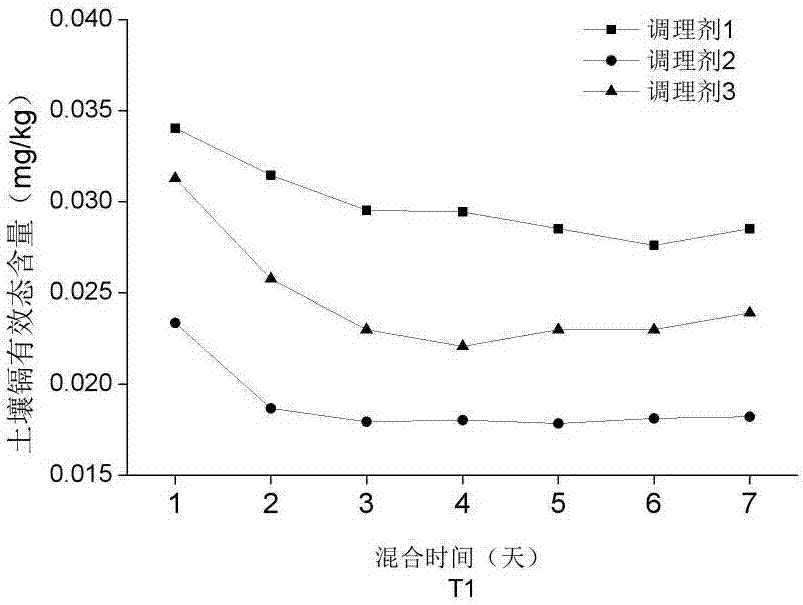

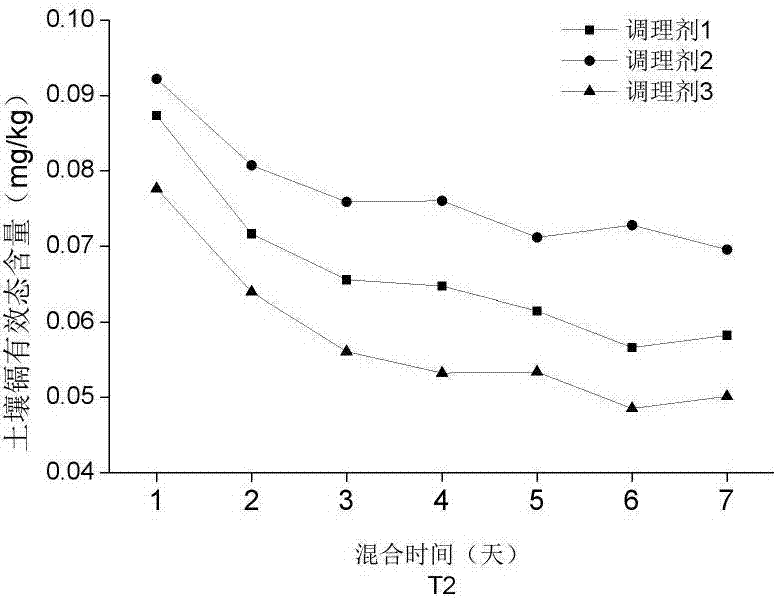

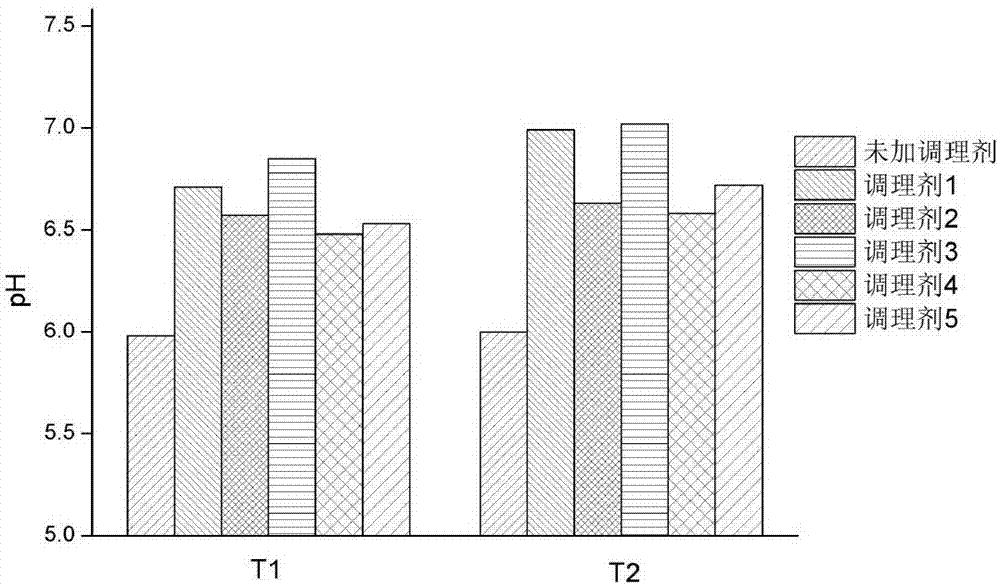

[0038] The mulberry branches are cleaned centrally to remove soil and gravel, after being dried and coarsely crushed, they are pyrolyzed under anaerobic conditions at 400-600°C to generate biochar, which is pre-crushed by a ball mill. Biochar, bentonite (Santai Guanghua Bentonite Co., Ltd., Sichuan Province) and commercially available calcium magnesium phosphate fertilizer (P 2 o 5 Content 18%, CaO content 40%, water soluble SiO 2 content of 25%, MgO content of 8%) to mix, fully mix and pass through a 100-mesh sieve for later use. According to the actual situation of the soil, the dosage of the composition is 0.25%-0.5% of the weight of the dry soil, and it is mixed into the soil 3-7 days before sowing the paddy rice.

Embodiment 2

[0040] The mulberry branches are cleaned centrally to remove soil and gravel, after being dried and coarsely crushed, they are pyrolyzed under anaerobic conditions at 400-600°C to generate biochar, which is pre-crushed by a ball mill. Biochar, bentonite (Santai Guanghua Bentonite Co., Ltd., Sichuan Province) and commercially available calcium magnesium phosphate fertilizer (P 2 o 5 Content 18%, CaO content 40%, water soluble SiO 2content of 25%, MgO content of 8%) to mix, fully mix and pass through a 100-mesh sieve for later use. According to the actual situation of the soil, the dosage of the composition is 0.5%-1.5% of the weight of the dry soil, and it is mixed into the soil 3-7 days before the rice is sown.

Embodiment 3

[0042] The mulberry branches are cleaned centrally to remove soil and gravel, after being dried and coarsely crushed, they are pyrolyzed under anaerobic conditions at 400-600°C to generate biochar, which is pre-crushed by a ball mill. Biochar, bentonite (Santai Guanghua Bentonite Co., Ltd., Sichuan Province) and commercially available calcium magnesium phosphate fertilizer (P 2 o 5 Content 18%, CaO content 40%, water soluble SiO 2 content of 25%, MgO content of 8%) to mix, fully mix and pass through a 100-mesh sieve for later use. According to the actual situation of the soil, the dosage of the composition is 1%-2% of the weight of the dry soil, and it is mixed into the soil 3-7 days before the rice is sown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com