High-shading-performance polycarbonate wire suitable for fused deposition and preparation method thereof

A polycarbonate, fused deposition technology, applied in the field of additive manufacturing, can solve the problems of difficult to meet the toughness of the wire, melting temperature, viscosity, mechanical properties, complicated processes, low impact resistance, etc., to shorten the research and development cycle and Production cost, simple operation process, and the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

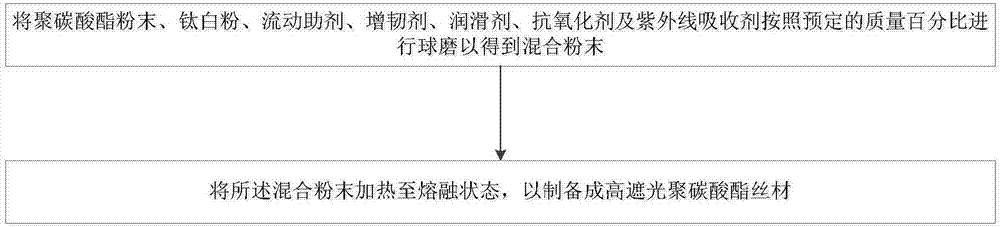

[0024] see figure 1 , the preparation method of the high light-shielding polycarbonate filament material suitable for fusion deposition provided by the preferred embodiment of the present invention, the preparation method mainly includes the following steps:

[0025] Step 1, ball milling polycarbonate powder, titanium dioxide, flow aid, toughening agent, lubricant, antioxidant and ultraviolet absorber according to a predetermined mass percentage to obtain a mixed powder. Specifically, the polycarbonate powder, the titanium dioxide, the flow aid, the toughening agent, the lubricant, the antioxidant and the ultraviolet absorber are weighed according to a predetermined mass percentage and pour it into a ball mill jar, and then add a certain amount of balls into the ball mill jar to perform ball milling to obtain a uniformly dispersed mixed powder. In this embodiment, the mass percentage of the polycarbonate powder is 49-78%; the mass percentage of the titanium dioxide is 9-13%; ...

Embodiment 1

[0031] The preparation method of the highly light-shielding polycarbonate filament material suitable for fusion deposition provided by embodiment 1 comprises the following steps:

[0032] (11) Preparation of high light-shielding PC powder: Weigh 780g PC powder, 90g titanium dioxide, 100g PBT flow aid, 20g A-662R toughening agent, 1g stearyl stearate and paraffin mixed lubricant, 5g antioxidant 168 and the ultraviolet absorber of 5g UV-5411 type are prepared into 1000g composite powder altogether, then described composite powder is poured in the ball mill jar, and in described ball mill jar, add 800g ball, on ball mill with Ball mill at a speed of 200r / min for 120min to obtain a uniformly dispersed mixed powder.

[0033] (12) Wire forming: the mixed powder obtained in step (11) is heated to a molten state and then passed through a single-screw extruder with a solid delivery zone temperature of 120°C, a plasticizing zone temperature of 210°C, and a barrel vacuum The diameter of...

Embodiment 2

[0035] The preparation method of the highly light-shielding polycarbonate filament material suitable for fusion deposition provided by embodiment 2 comprises the following steps:

[0036] (21) Preparation of high light-shielding PC powder: Weigh 700g PC powder, 120g titanium dioxide, 120g PET flow aid, 40g HHB-E009 toughening agent for toughened polyester, 5g montan wax acid soap ester lubricant, The ultraviolet absorber of 10g antioxidant TPPI and 5gUV-1577 type, to be prepared into 1000g composite powder, then described composite powder is poured in the ball mill jar, and in described ball mill jar, add 700g ball, on the ball mill with rotating speed 150r / min ball milling for 240min to obtain a uniformly dispersed mixed powder.

[0037] (22) Wire forming: the mixed powder obtained in step (21) is heated to a molten state and then passed through a single-screw extruder with a temperature of 130°C in the solid conveying zone, a temperature of 220°C in the plasticizing zone, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com