A kind of preparation method of metal matrix composite material

A composite material and metal-based technology, applied in the field of metal-based composite material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

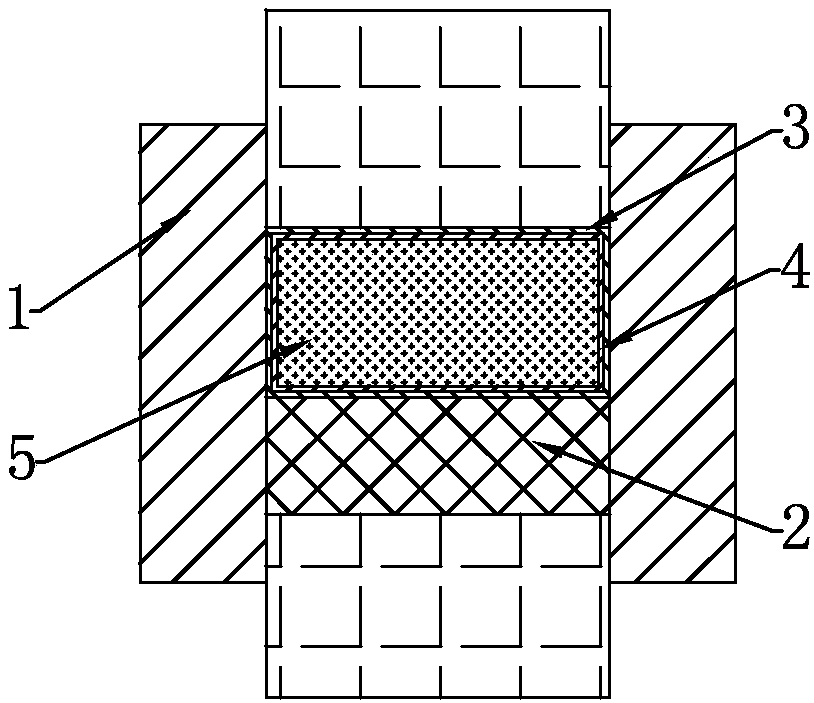

[0028] see figure 1 , the high-melting-point component and the low-melting-point metal component of the metal matrix composite material in this embodiment use silicon powder and aluminum powder respectively, and its preparation method is as follows:

[0029] 1) Take the aluminum powder and silicon powder required for the preparation of materials according to the volume ratio of 1:1, put them into the mixer, and mix the materials to obtain the mixed powder 5, which is set aside;

[0030] 2) Put the mixed powder 5 prepared in step (1) into the thin-walled stainless steel sheath 3, one end of the sheath 3 is welded and closed with a stainless steel sheet; the inside of the sheath 3 is lined with graphite paper 4, pre-pressed at 20MPa, 5min, Then plug the other end of the closed sheath 3 with a plug 2 slightly larger than the inner diameter of the sheath 3, and put it into the mold 1;

[0031] 3) Put the mold 1 filled with the thin-wall stainless steel sheath 3 in step (2) into a...

Embodiment 2

[0036] see figure 1 , the high-melting-point component and the low-melting-point metal component of the metal matrix composite material in this embodiment use silicon carbide powder and aluminum powder respectively, and its preparation method is as follows:

[0037] 1) Take the aluminum powder and silicon carbide powder required for the preparation of materials according to the volume ratio of 45:55, put them into the mixer, and mix the materials to obtain the mixed powder 5, which is set aside;

[0038] 2) Put the mixed powder 5 prepared in step (1) into a thin-walled carbon steel sheath 3, one end of the sheath 3 is welded and closed with a stainless steel sheet, the inside of the sheath 3 is lined with graphite paper 4, and then the inner diameter of the sheath is slightly larger than that of the sheath The plug 2 plugs the other end of the closed sheath and packs it into the mold 1;

[0039] 3) Put the mold 1 packed in the thin-walled stainless steel sheath in step (2) in...

Embodiment 3

[0044] see figure 1 , the high-melting-point component and the low-melting-point metal component of the metal matrix composite material in this embodiment use tungsten powder and copper powder respectively, and its preparation method is as follows:

[0045] 1) Take the tungsten powder and copper powder required for the preparation of materials according to the volume ratio of 52:48, put them into the mixer, and mix the materials to obtain the mixed powder 5, which is set aside;

[0046] 2) Put the mixed powder 5 prepared in step (1) into a thin-walled stainless steel ladle 3, one end of the sheath 3 is welded and closed with a stainless steel sheet, the inside of the sheath 3 is lined with graphite paper 4, pre-pressed at 30MPa for 5min, and then Plug the other end of the closed sheath with a plug slightly larger than the inner diameter of the sheath, and put it into the mold 1;

[0047] 3) Put the mold 1 packed in the thin-walled stainless steel sheath in step (2) into a hot-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com