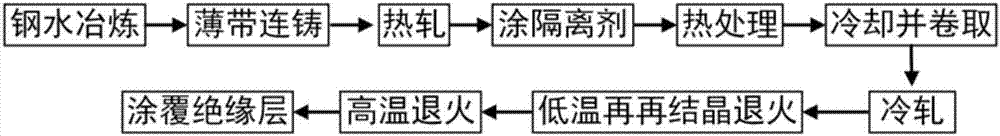

Method for preparing rotating cubic dual-oriented silicon steel based on thin-strip casting

A dual-oriented, cubic technology, applied in the field of metallurgy, can solve the problem of no more reports, and achieve the effect of simple and feasible process and high magnetic properties of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

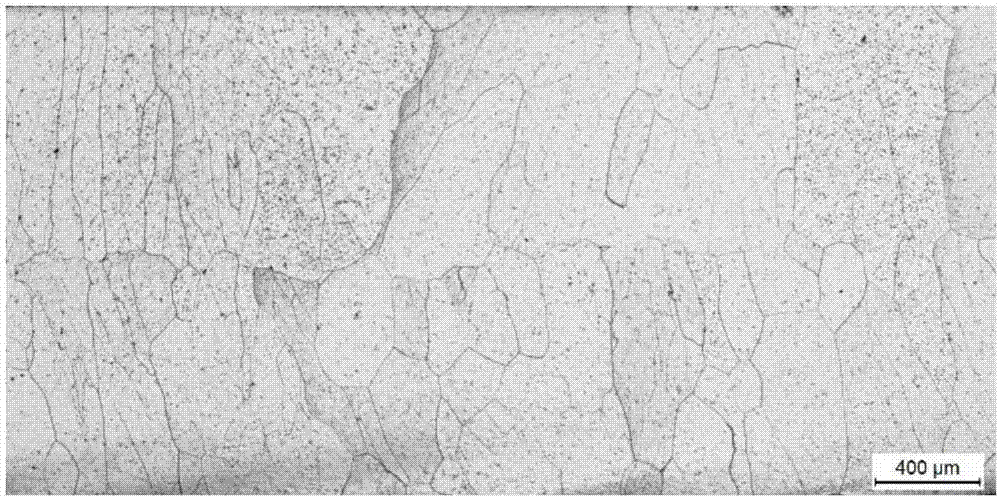

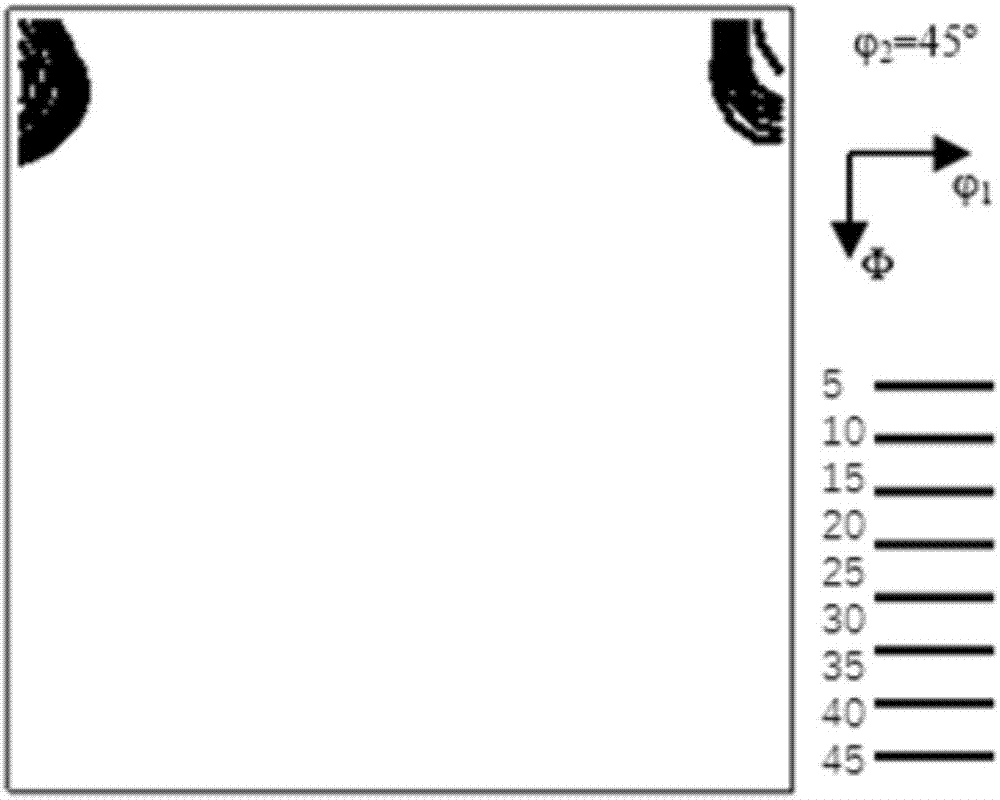

Examples

Embodiment 1

[0034] In this embodiment, the method for preparing rotating cubic double-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0035] Smelting molten steel according to the set composition, its composition by weight percentage is: C 0.01%, Si 1.6%, Mn0.0025%, V 0.03%, Al 0.0044%, P 0.0075%, S 0.002%, N 0.0016%, O 0.0013% , Nb0.0011%, Ti 0.0018%, the balance is Fe;

[0036] Strip continuous casting process: molten steel enters the tundish through the gate, the preheating temperature of the tundish is 1200°C, and the superheating degree is controlled at 60°C. The molten steel enters the thin strip continuous casting machine through the tundish to form a casting strip, and the casting speed is controlled at 50m / min, control the height of molten pool liquid level to 140mm, and control the thickness of casting belt to 2.8mm;

[0037] After the cast strip is taken out of the roll, it is naturally cooled to a hot r...

Embodiment 2

[0043] In this embodiment, the method for preparing rotating cubic double-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0044] Smelting molten steel according to the set composition, its composition by weight percentage is: C 0.03%, Si 2.0%, Mn0.0027%, V 0.04%, Al 0.0037%, P 0.0068%, S 0.004%, N 0.0012%, O 0.0018% , Nb0.0016%, Ti 0.0012%, the balance is Fe;

[0045] Strip continuous casting process: molten steel enters the tundish through the gate, the preheating temperature of the tundish is 1220°C, and the superheating degree is controlled at 50°C. The molten steel enters the thin strip continuous casting machine through the tundish to form a casting strip, and the casting speed is controlled at 40m / min, control the height of molten pool liquid level to 130mm, and control the thickness of casting belt to 2.5mm;

[0046] After the cast strip is taken out of the roll, it is naturally cooled to a hot r...

Embodiment 3

[0052] In this embodiment, the method for preparing rotating cubic double-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0053] Smelting molten steel according to the set composition, its composition by weight percentage is: C 0.05%, Si 3.3%, Mn0.0022%, V 0.05%, Al 0.0037%, P 0.0056%, S 0.005%, N 0.0016%, O 0.0013% , Nb0.0008%, Ti 0.0007%, the balance is Fe;

[0054] Strip continuous casting process: molten steel enters the tundish through the gate, the preheating temperature of the tundish is 1250°C, and the superheating degree is controlled to 40°C, the molten steel enters the thin strip continuous casting machine through the tundish to form a casting strip, and the casting speed is controlled at 60m / min, control the height of molten pool liquid level to 150mm, and control the thickness of casting belt to 2.0mm;

[0055] After the cast strip comes out of the roll, it is naturally cooled to a hot roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com