Method for producing superphosphoric acid through concentrating thin-phosphoric acid by using phosphorus combustion heat

A technology of dilute phosphoric acid and phosphorus combustion, applied in chemical instruments and methods, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, sustainable manufacturing/processing, etc., can solve the problem of product SPA flow Poor performance, large heat consumption, high impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

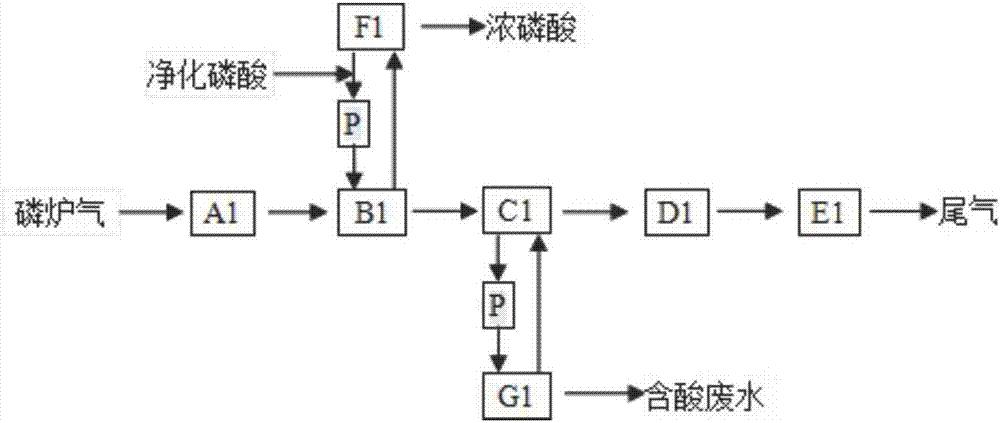

[0053] This embodiment provides a method for producing superphosphoric acid by concentrating dilute phosphoric acid with phosphorus combustion heat, and the process flow is as follows figure 1 shown, including the following steps:

[0054] (1) With phosphorus furnace (tail) gas (ω(P 4 ) 0.436%, T=65 ℃, ω (CO) 89%) as phosphorus source, under aerobic condition, carry out full combustion in the hot blast furnace A1, obtain the high-temperature gas containing phosphorus pentoxide (ω (P 2 o 5 )0.125%, T=1365°C);

[0055] (2) Pass the high-temperature gas described in step (1) into the absorption tower B1, and utilize the circulating phosphoric acid from the circulating acid tank F1 to absorb the high-temperature gas in the P 2 o 5 At the same time, high-temperature gas is also used to evaporate the moisture in the circulating phosphoric acid to obtain the product concentrated phosphoric acid (ω(P 2 o 5 )61.5%) and medium-temperature gas (T=135°C); the product concentrated ph...

Embodiment 2

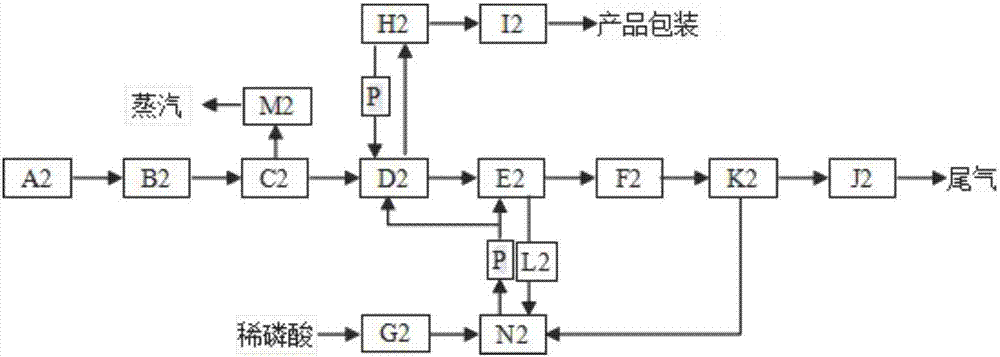

[0058] This embodiment provides a method for producing superphosphoric acid by concentrating dilute phosphoric acid with phosphorus combustion heat, and the process flow is as follows figure 2 shown, including the following steps:

[0059] (1) The yellow phosphorus (ω(P) in the yellow phosphorus storage tank A2 4 )99.8%), introduce phosphorus combustion tower C2 through phosphorus supply equipment B2, carry out full combustion under aerobic conditions, obtain the high-temperature gas (ω(P 2 o 5 )25.36%, T=250°C);

[0060] (2) the high-temperature gas described in step (1) is passed into the absorption tower D2, and the phosphorus pentoxide in the high-temperature gas is absorbed by the absorption cycle phosphoric acid from the absorption cycle acid tank H2 to obtain the first concentrated phosphoric acid (ω(P 2 o 5 )69.6%, T=192°C) and medium temperature gas (T=258°C);

[0061] (3) the medium-temperature gas obtained by step (2) is passed into evaporation tower E2, and t...

Embodiment 3

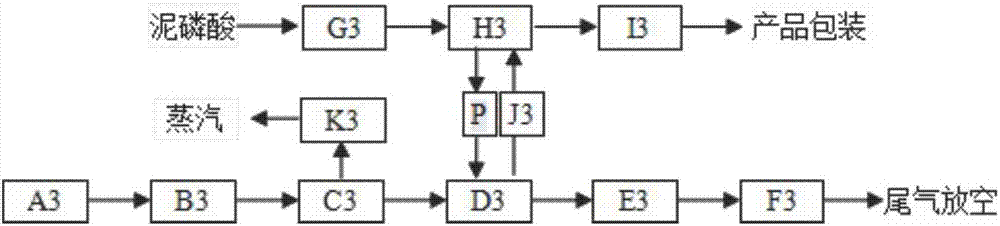

[0065] This embodiment provides a method for producing superphosphoric acid by concentrating dilute phosphoric acid with phosphorus combustion heat, and the process flow is as follows image 3 shown, including the following steps:

[0066] (1) The yellow phosphorus (ω(P) in the yellow phosphorus storage tank A3 4 )99.8%), introduce horizontal phosphorus combustion furnace C3 through phosphorus supply equipment B3, fully burn under aerobic conditions, obtain high-temperature gas containing phosphorus pentoxide (ω(P 2 o 5 )26.31%, T=760°C);

[0067] (2) The high-temperature gas described in step (1) is passed into the absorption tower D3, while the phosphorus pentoxide in the high-temperature gas is absorbed by the circulating phosphoric acid from the absorption cycle acid tank H3, the high-temperature gas is also used to evaporate the circulating phosphoric acid Medium H 2 O, get concentrated phosphoric acid (ω(P 2 o 5 )69.4%, T=138°C, which is superphosphoric acid) and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com