A kind of PVC paint film and preparation method thereof

A PVC film and paint film technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of lack of ductility of coatings, cracking of coatings, poor weather resistance and scratch resistance of surface coatings, etc. Improve overall performance and application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

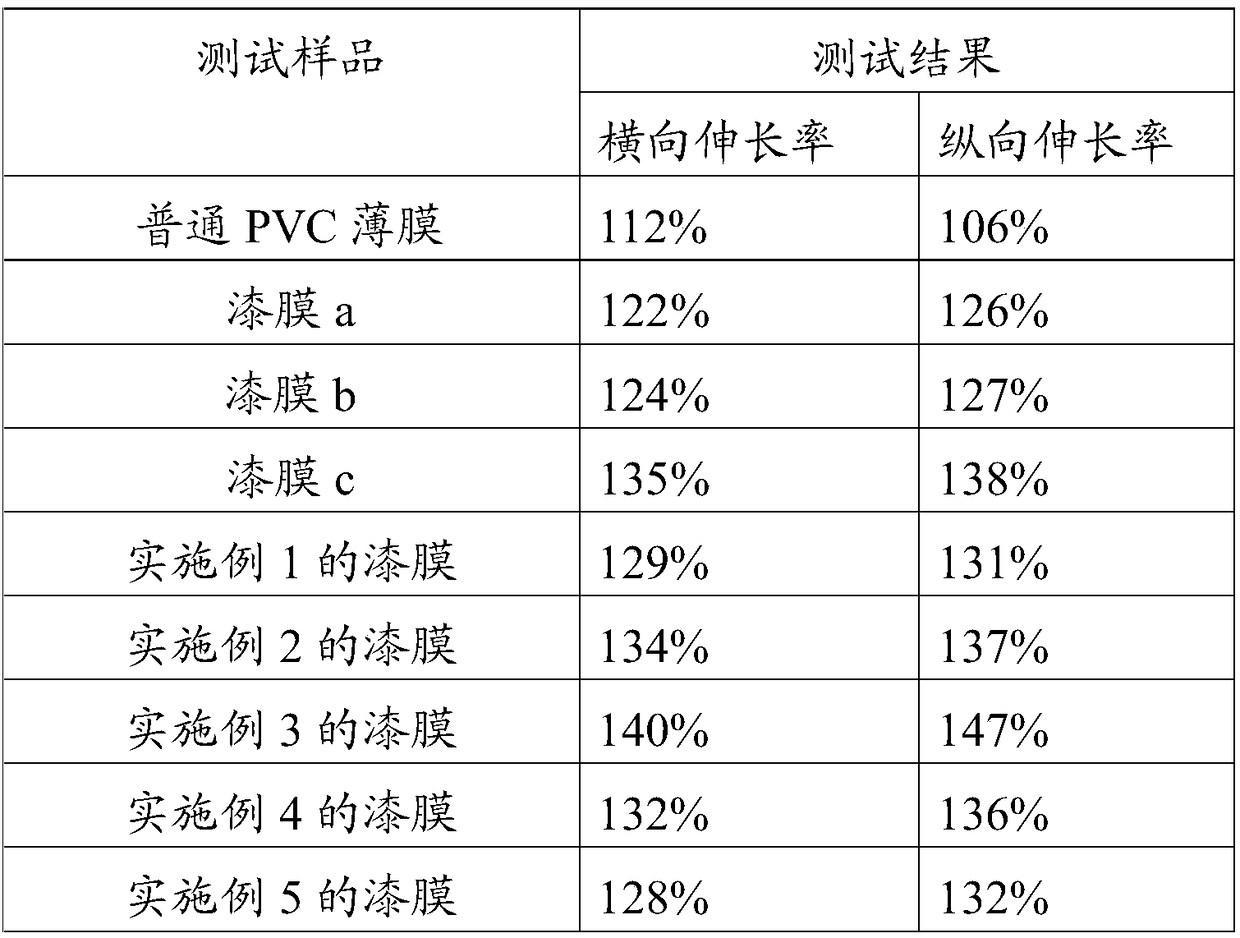

Examples

Embodiment 1

[0021] A kind of embodiment of PVC paint film of the present invention, its preparation method comprises the following steps: (1) at first, stir hydroxyacrylic acid resin with mixer 2 minutes, make its system uniform, then weigh 100 parts by weight, then, Then weigh 33.3 parts by weight of hexamethylene diisocyanate, and add 33.3 parts by weight of methyl ethyl ketone, make it fully mixed with hexamethylene diisocyanate, slowly add to the weighed hydroxyacrylic acid resin while stirring Then add the copper powder of 0.1 weight part, and the benzophenone of 0.8 weight part and stir evenly, measure the viscosity of the mixed material with the viscosity cup, utilize the solvent to regulate the viscosity of material in 14 seconds, finally, adjust Good materials are added to the circulation pump and wait to start;

[0022] (2) Unwinding: Install the prepared PVC film on the unwinding machine, and pull it through the coating roller, then through the oven, and finally fix it on the w...

Embodiment 2

[0027] A kind of embodiment of PVC paint film of the present invention, its preparation method comprises the following steps: (1) at first, stir polyether resin with mixer 2.5 minutes, make its system uniform, then weigh 100 parts by weight, then, weigh again Measure 28 parts by weight of isocyanate, and add 28 parts by weight of ethyl acetate, make it fully mixed with isocyanate, slowly add it to the weighed polyether resin while stirring; then add 0.8 parts by weight of pearl powder, and 0.7 parts by weight Stir the benzophenone in parts by weight evenly, measure the viscosity of the mixed material with a viscosity cup, adjust the viscosity of the material to 15 seconds with a solvent, and finally, add the adjusted material to the circulating pump and wait for the machine to start;

[0028] (2) Unwinding: Install the prepared PVC film on the unwinding machine, and pull it through the coating roller, then through the oven, and finally fix it on the winding machine;

[0029] (...

Embodiment 3

[0033] A kind of embodiment of PVC paint film of the present invention, its preparation method comprises the following steps: (1) at first, stir hydroxyacrylic acid resin with mixer 3 minutes, make its system uniform, then weigh 100 parts by weight, then, Then weigh 22 parts by weight of hexamethylene diisocyanate, and add 22 parts by weight of cyclohexanone, make it fully mixed with hexamethylene diisocyanate, slowly add to the weighed hydroxyacrylic acid while stirring In the resin; Then add the aluminum silver paste of 2 weight parts, and the benzotriazole of 0.5 weight part and stir evenly, measure the viscosity of the mixed material with the viscosity cup, utilize the solvent to regulate the viscosity of material in 16 seconds, at last, Add the adjusted material to the circulation pump and wait for it to start;

[0034] (2) Unwinding: Install the prepared PVC film on the unwinding machine, and pull it through the coating roller, then through the oven, and finally fix it o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com