Safety and large-capacity lithium ion battery

A lithium-ion battery, high-capacity technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problem of difficulty in manufacturing core packs to dissipate heat, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

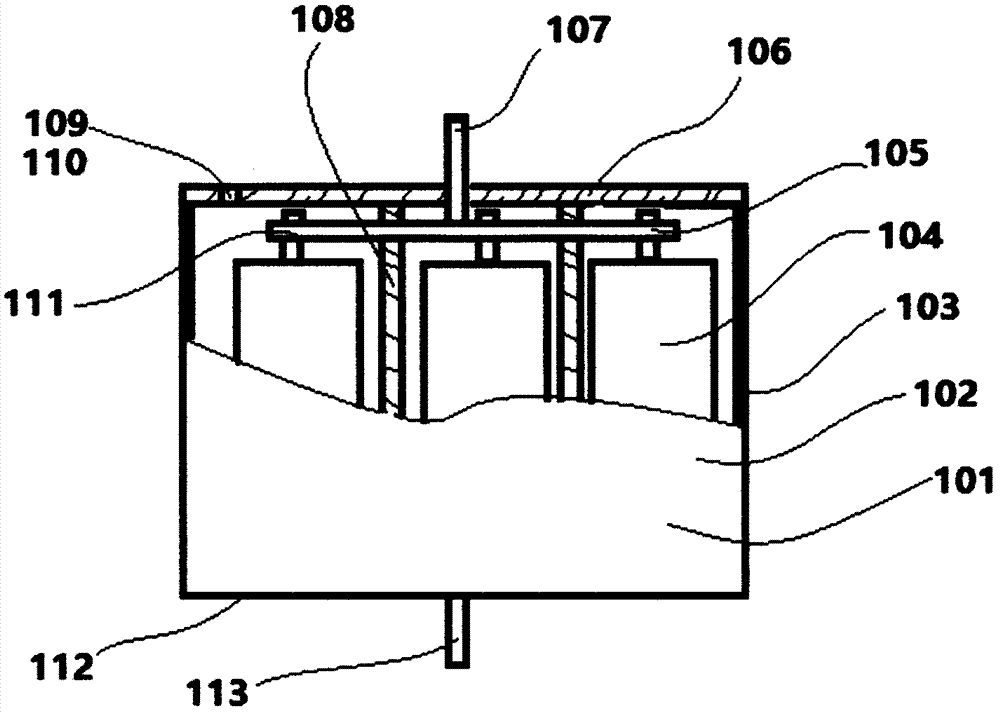

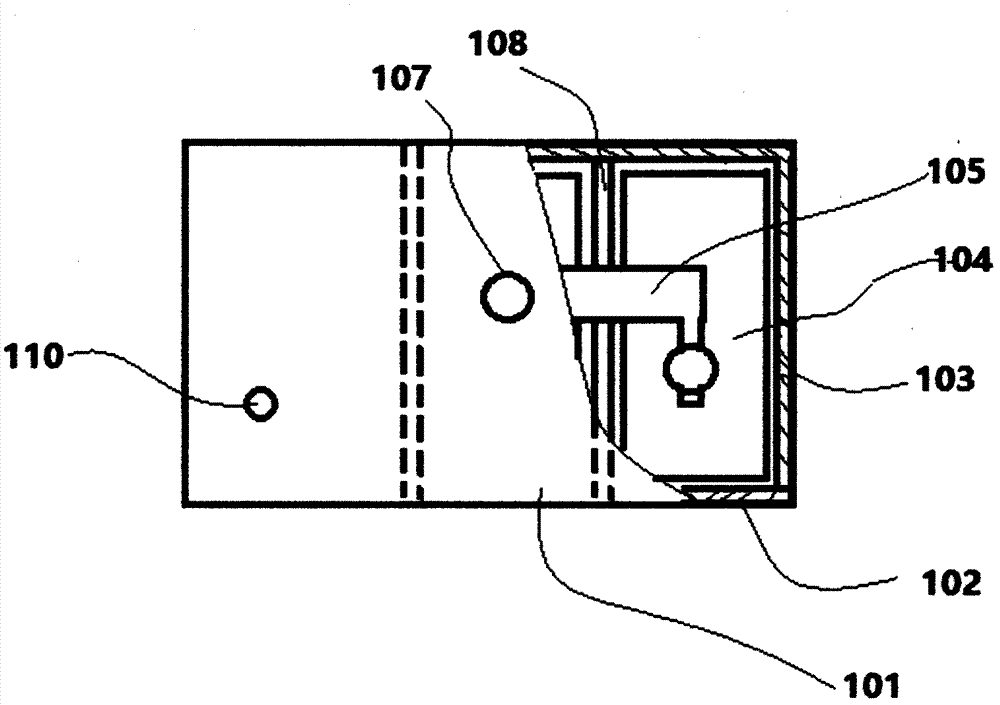

[0024] In order to illustrate the present invention, a 450Ah lithium ion battery was made in this embodiment, and the shape is as figure 1 Shown. Lithium-ion battery cathode materials usually use LiFePO 4 , LiNiCoMnO 2 , LiNiCoAlO 2 , LiMn 2 O 4 , LiCoO2, or a mixture of two of them, the anode material uses C, Li 4 T i5 O 12 , Si or its compound, Sn or its compound, the electrolyte adopts 1.2MLiPF 6 +EC+EMC, the diaphragm adopts PE film, PP film, PP / PE film, coated with SiO 2 Or Ai 2 O 3 PE composite film.

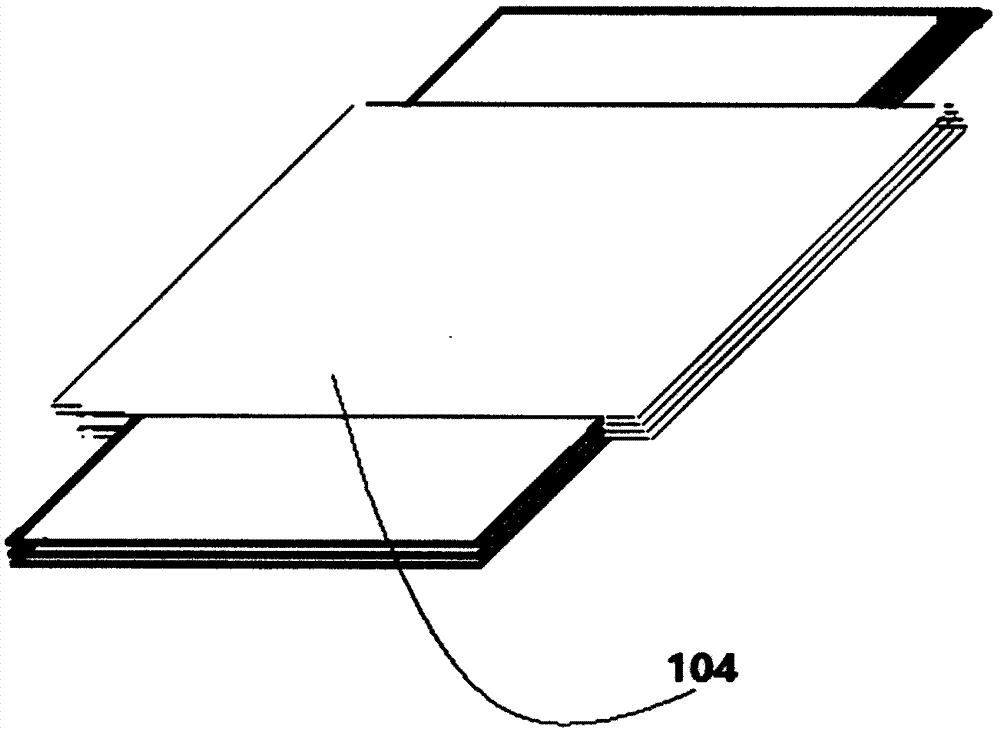

[0025] Pre-made belt The injection hole 109, equipped with The aluminum positive pole cover plate 106 of the aluminum positive pole 107; The aluminum negative electrode end cover 112 of the copper negative pole 113; the aluminum and copper current limiting connectors 105 are made of 2mm thick aluminum sheet and 1mm copper sheet, respectively; 48×405mm is made of 2mm thick aluminum sheet, with 2 Thermally conductive separator 108 with through-hole 501; 225×410mm battery shel...

Embodiment 2

[0030] Make 450Ah lithium-ion battery, looks like figure 1 Shown. Except that the small core pack adopts a winding rectangular parallelepiped structure, the other battery materials, methods and dimensions are the same as those of Example 1. The coating width and smooth edge width of the positive and negative plates are the same as in Example 1. The positive and negative pole pieces of the entire roll are respectively cut into 377mm and 378mm wide positive and negative pole piece rolls, and the entire roll of separator is cut into 368mm wide. Diaphragm sheet roll; use a winding machine to roll into a core with a thickness of 8mm, a length of 388mm, and a width of 72mm. The six cores are ultrasonically welded, or laser welded, or riveted to connect the positive and negative sides of the core respectively. As a whole, a small core pack 104 with a winding rectangular parallelepiped structure is made; using the same method as in Example 1, three small core packs 104 are connected in...

Embodiment 3

[0032] Using the battery made in Example 1, after the battery is fully charged, an external short circuit test of the battery is performed with a wire. The result of the experiment is that the battery is safe. After disassembling the battery, it can be seen that the aluminum current-limiting connector 105 is fused, indicating that the current-limiting connector 105 plays a role of current limiting. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com