Preparation method for improving walnut protein processing characteristics

A technology of walnut protein and processing characteristics, applied in the field of vegetable protein modification, can solve problems such as limited application and poor functional characteristics, and achieve the effect of solving resource waste and improving processing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

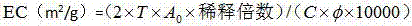

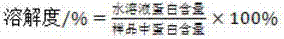

[0022] Take 10g of walnut degreased powder and 150ml of water and mix it at a ratio of 1:15 g / mL to liquid, adjust the protein solution to pH 9.0 with 0.5 mol / L NaOH, centrifuge at 5000 r / min for 10 min, collect the supernatant, and use 0.5 mol / L NaOH to adjust the protein solution to pH 9.0. / L HCl to adjust the pH of the supernatant to 5.0, the protein solution was centrifuged at 5000 r / min for 10 min, the precipitate was collected and washed 5 times to neutral, freeze-dried to obtain walnut protein; weigh 1.0 g walnut protein, dissolve in 200mL phosphoric acid Buffer solution (pH 7.0 10 mmol / L), the walnut protein solution was treated at 600W ultrasonic power for 30min, and the ultrasonic frequency was 25 kHz; the walnut protein solution after ultrasonic treatment was freeze-dried at a temperature of -50°C and a vacuum of 1.33 Pa, namely Highly soluble walnut protein powder can be obtained, and the moisture content of the protein powder is less than 10%.

Embodiment 2

[0024] Take 10g of walnut degreased powder and 150ml of water and mix it at a ratio of 1:15 g / mL to liquid, adjust the protein solution to pH 9.0 with 0.5 mol / L NaOH, centrifuge at 5000 r / min for 10 min, collect the supernatant, and use 0.5 mol / L NaOH to adjust the protein solution to pH 9.0. / L HCl to adjust the pH of the supernatant to 5.0, the protein solution was centrifuged at 5000 r / min for 10 min, the precipitate was collected and washed 5 times to neutral, freeze-dried to obtain walnut protein; weigh 1.0 g walnut protein, dissolve in 200mL phosphoric acid Buffer solution (pH7.0 10 mmol / L), the walnut protein solution was treated at 500W ultrasonic power for 30min, the ultrasonic frequency was 25 kHz, and the walnut protein solution after ultrasonic treatment was freeze-dried at the temperature of -50°C and the vacuum degree of 2.00 Pa, namely Highly emulsifying walnut protein powder can be obtained, and the moisture content of the protein powder is less than 10%.

Embodiment 3

[0026] Take 10g of walnut degreased powder and 150ml of water and mix it at a ratio of 1:15 g / mL to liquid, adjust the protein solution to pH 9.0 with 0.5 mol / L NaOH, centrifuge at 5000 r / min for 10 min, collect the supernatant, and use 0.5 mol / L NaOH to adjust the protein solution to pH 9.0. / L HCl to adjust the pH of the supernatant to 5.0, the protein solution was centrifuged at 5000 r / min for 10 min, the precipitate was collected and washed 5 times to neutral, freeze-dried to obtain walnut protein; weigh 1.0 g walnut protein, dissolve in 200mL phosphoric acid Buffer solution (pH7.0 10 mmol / L), the walnut protein solution was treated at 400W ultrasonic power for 15min, the ultrasonic frequency was 25 kHz, and the walnut protein solution after ultrasonic treatment was freeze-dried at -50°C and vacuum degree 2.66 Pa, namely Walnut protein powder with high emulsification stability can be obtained, and the moisture content of the protein powder is less than 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com