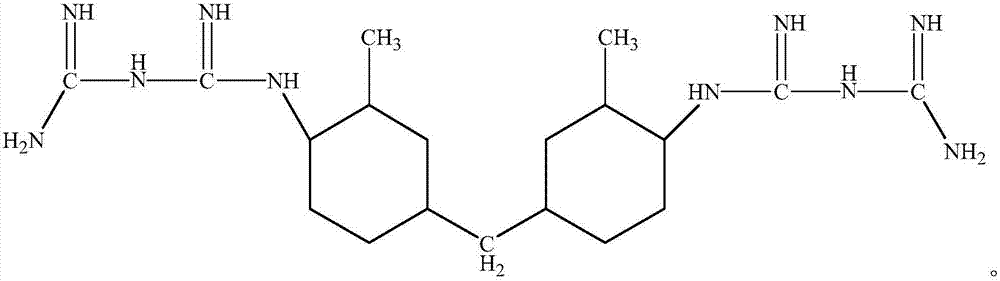

Application of novel compound 3, 3'-dimethyl(p-biguanide) methane dicyclohexyl in epoxy resin system

A technology of dicyclohexylmethane and epoxy resin system, which is applied in the direction of organic chemistry, can solve the problems of high epoxy resin temperature and poor compatibility of epoxy resin, achieve rapid curing, good heat resistance, and improve toughness good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of novel curing agent 3,3'-dimethyl (p-biguanide group) dicyclohexylmethane described in the present invention, but not limited to the synthesis method. The synthesis method is as follows: under an inert atmosphere, dicyandiamide and 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane (DMDC) are mixed in a molar ratio of 2:(1~1.5) in a solvent, and react at a constant temperature of 100-120°C for 6-8 hours under acid catalysis, and obtain 3,3'-dimethyl (p-biguanide) dicyclohexylmethane after removal of impurities. More specific steps are as follows:

[0028] (1) feed argon before the reaction to get rid of the air in the reaction system, dicyandiamide, DMDC, hydrochloric acid (37%) are mixed in the solvent water according to the molar ratio of 2:1:3.5, the pH value of the reaction system is controlled at Between 3 and 4, while argon gas is kept flowing, open the condensing reflux device, raise the temperature to 100°C and stir at a constant temperature...

Embodiment 1

[0039] A kind of application method of novel compound 3,3'-dimethyl (p-biguanide group) dicyclohexyl methane in epoxy resin system, its steps are as follows:

[0040] (1) In terms of parts by mass, weigh 100 parts of E51 epoxy resin, 11 parts of 3,3'-dimethyl (p-biguanide) dicyclohexylmethane, stir well, and then place the container containing the mixture in Vibrate in an ultrasonic cleaner, take it out and mix evenly, pour, defoam, and heat to 80°C for 2 hours;

[0041] (2) Post-curing: the product obtained in step (1) was cured at 110° C. for 2 hours to obtain a cured epoxy resin system. The impact strength of the cured epoxy resin system increased by 30.4%, and the toughness increased by 25.8%.

Embodiment 2

[0043] A kind of application method of novel 3,3'-dimethyl (p-biguanide group) dicyclohexyl methane in epoxy resin system, its steps are as follows:

[0044] (1) In terms of parts by mass, weigh 100 parts of E44 epoxy resin, 11 parts of 3,3'-dimethyl (p-biguanide) dicyclohexylmethane, and 2 parts of imidazole accelerator for preparation, and mix the three evenly Finally, hand lay-up molding, curing at room temperature for 5 hours;

[0045] (2) Post-curing: the product obtained in step (1) was cured at 90° C. for 3 hours to obtain a cured epoxy resin system. The impact strength of the cured epoxy resin system increased by 32.5%, and the toughness increased by 26.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com