UV ink having reversible thermochromic capacity and used for PVC (polyvinyl chloride), preparation method and use method

A technology of temperature-sensitive color-changing pigments and inks, applied in the field of printing inks, can solve the problems of less research on temperature-sensitive color-changing temperature control and high ink prices, and achieve the effects of avoiding product quality degradation, convenient operation, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention proposes a kind of preparation method of temperature-sensitive reversible discoloration UV ink for PVC, and it comprises the following steps:

[0034] Premixing: Mix the prepolymer, monomer, accelerator and defoamer, and stir at 60-85°C to obtain the mixture;

[0035] Pigment dispersion: Then add thermochromic pigments, photoinitiators, and dispersants into the mixture, and stir.

[0036] First, through the pre-mixing process, the pre-polymer, monomer, accelerator and defoamer are pre-mixed at a certain temperature. During this process, the temperature is relatively high to ensure that the materials can be mixed effectively. In addition, preliminary stirring and mixing of the above raw materials can form a uniform and stable mixture, which is more convenient for the subsequent addition of pigments. In addition, the pre-mixing process can avoid premature addition of pigments, photoinitiators, etc., which will be greatly affected during subsequent o...

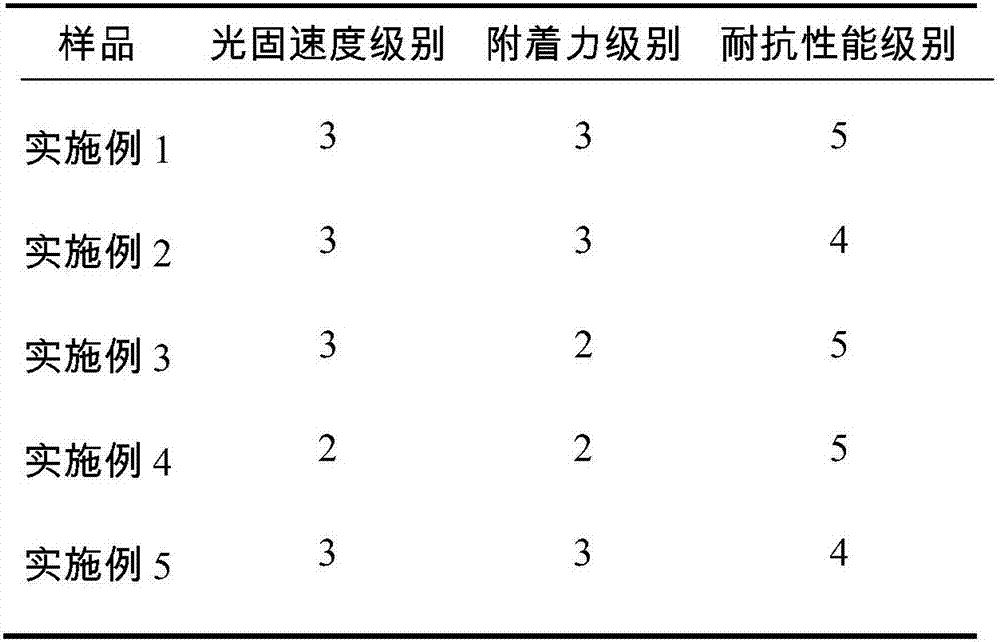

Embodiment 1

[0043] A temperature-sensitive reversible discoloration UV ink for PVC provided in this embodiment, in terms of weight percentage, its raw materials include the following components: 37.41% epoxy acrylic resin, 45.35% hexanediol diacrylate, trimethylbenzene Formyl diphenyl phosphine oxide 6.02%, active amine 3.74%, active content polymer dispersant 1.2%, silicone oil defoamer 1.02%, thermochromic powder 5.26%.

[0044] The above raw materials are analytically pure.

[0045] The temperature-sensitive reversible discoloration UV ink for PVC is prepared according to the following steps:

[0046] a. Prepare materials: epoxy acrylic resin, hexanediol diacrylate, trimethylbenzoyl diphenyl phosphine oxide (I1), active amine, silicone oil defoamer, active content polymer dispersant and The temperature-sensitive color-changing powder is weighed one by one according to the above-mentioned raw material composition for later use, and the photoinitiator is taken as backup in step b.

[0...

Embodiment 2

[0050] A temperature-sensitive reversible discoloration UV ink for PVC provided in this embodiment, in terms of weight percentage, its raw materials include the following components: 50.11% epoxy acrylic resin, 30.04% hexanediol diacrylate, trimethylbenzene Formyl diphenyl phosphine oxide 8.04%, active amine 5.07%, active content polymer dispersant 0.7%, silicone oil defoamer 1.04%, thermochromic powder 5%.

[0051] The above raw materials are analytically pure.

[0052] The temperature-sensitive reversible discoloration UV ink for PVC is prepared according to the following steps:

[0053] a. Prepare materials: epoxy acrylic resin, hexanediol diacrylate, trimethylbenzoyl diphenyl phosphine oxide (I1), active amine, silicone oil defoamer, active content polymer dispersant and The temperature-sensitive color-changing powder is weighed one by one according to the above-mentioned raw material composition for later use, and the photoinitiator is taken as backup in step b.

[0054...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com