Heavy metal imprinted solid phase extraction material prepared by aid of microwave-reverse phase emulsion suspension and application of heavy metal imprinted solid phase extraction material

A technology of solid phase extraction materials and inverse emulsions, which is applied in the field of preparation of heavy metal imprinted solid phase extraction materials, can solve problems such as uneven heating, flocculation and precipitation, long reaction time of ion imprinted polymers, etc., to achieve shortened reaction time and simple operation , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

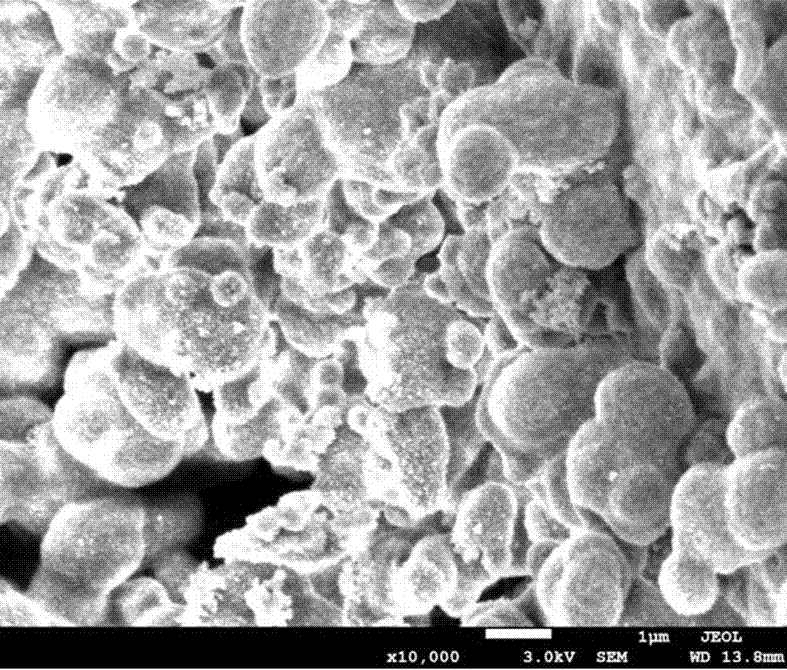

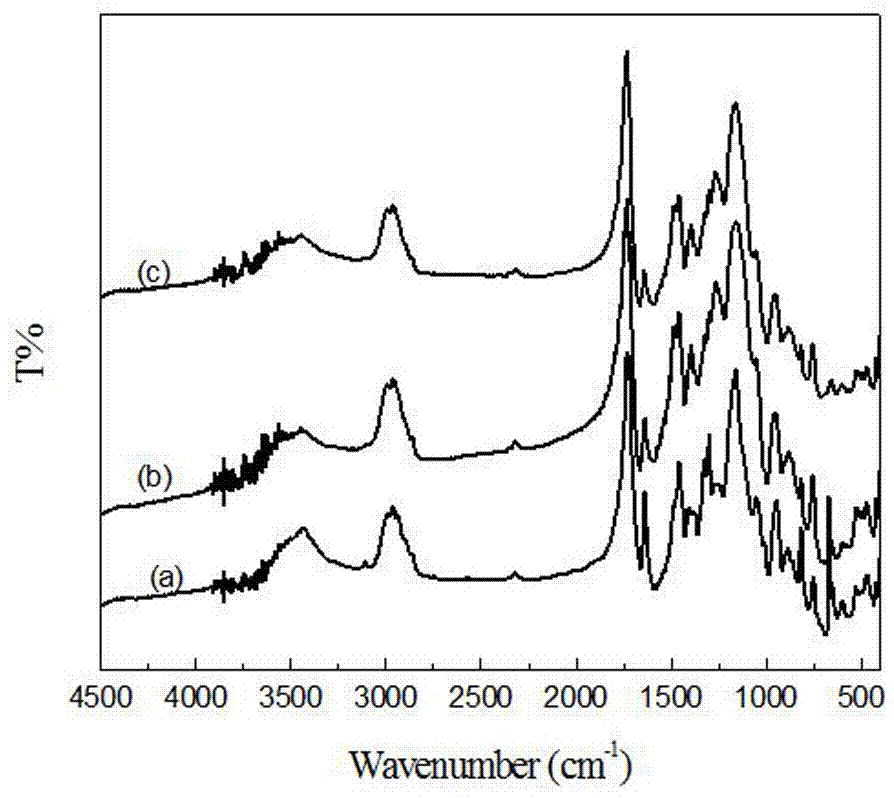

Embodiment 1

[0038] Add 0.3mmol of span80, 30mmol of cross-linking agent EGDMA, and 3mL of toluene to the three-necked flask, and 1mmol of CdCl 2 2.5H 2 O was dissolved in water, added to a three-necked flask, and 1 mmol of salicylaldehyde ethylenediamine Schiff base, a functional monomer, was added thereto, and stirred at 30° C. for 60 minutes at high speed to obtain an inverse emulsion. Add 3mmolFe 3 o 4 , continue stirring.

[0039] Weigh magnesium sulfate and SDBS with a molar ratio of 1:1 and dissolve them in water, add them into a three-neck flask, adjust the pH to 5, and continue stirring.

[0040] Raise the temperature to 70° C., add 1 mmol of azobisisobutyronitrile as an initiator, put it into a microwave reactor and react at 40 W for 30 minutes.

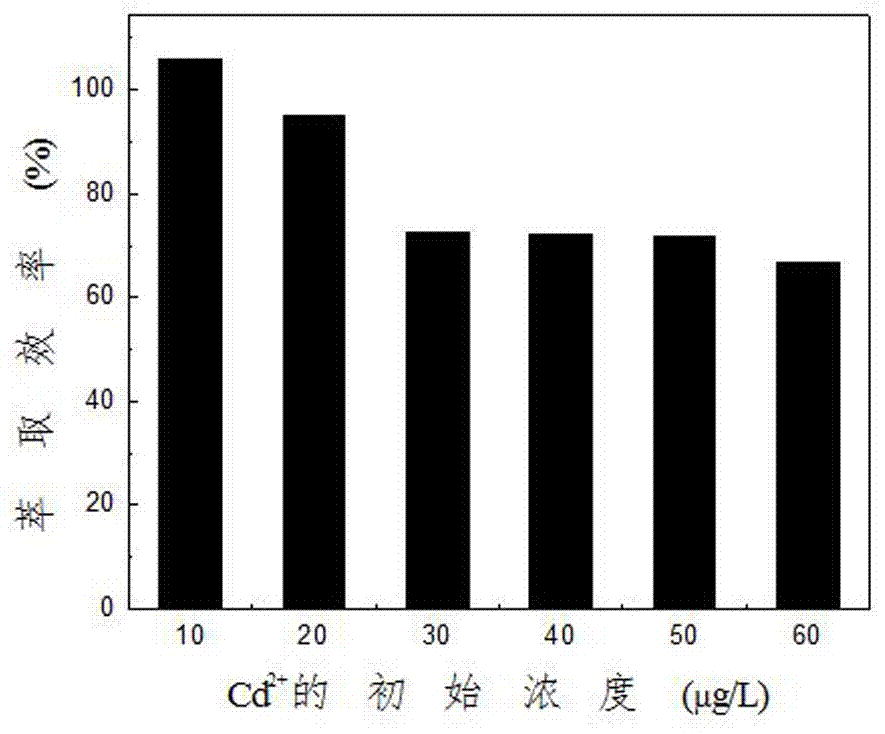

[0041] After the microwave is completed, the solution is filtered to obtain a spherical polymer, and the cadmium ions are eluted with a hydrochloric acid solution, shaken in a water bath at 20°C for 8 hours, and vacuum filtered to o...

Embodiment 2

[0049] Add 0.5mmol of span20, 40mmol of cross-linking agent trimethylolpropane trimethacrylate into the three-necked flask, and add 5mL of toluene, 0.2mmol of CuCl 2 Dissolve it in water, put it into a three-necked flask, add 20 mmol of functional monomer methoxy salicylaldehyde benzylamine Schiff's base, and stir at 40°C for 50 minutes at high speed to obtain an inverse emulsion. Add 5mmolFe 3 o 4 , continue stirring.

[0050] Weigh magnesium sulfate and SDBS with a molar ratio of 1:2 and dissolve them in water, add them into a three-necked flask, adjust the pH to 5, and continue stirring.

[0051] Raise the temperature to 70° C., add 5 mmol of azobisisoheptanonitrile as an initiator, put it into a microwave reactor and react at 640 W for 1 min.

[0052] After the microwave is completed, the solution is filtered to obtain a spherical polymer, and the cadmium ion is eluted with a hydrochloric acid solution, shaken in a water bath at 30°C for 7 hours, and vacuum filtered to ...

Embodiment 3

[0060] Add 0.1mmol of span40, 80mmol of cross-linking agent trimethylolpropane trimethacrylate into the three-necked flask, and add 8mL of toluene solvent, 3mmol of FeCl 3 ·6H 2 O was dissolved in water, added to a three-necked flask, and 30 mmol of functional monomer histidine salicylaldehyde Schiff base was added thereto, and stirred at 60° C. for 10 minutes at high speed to obtain an inverse emulsion. Add 2mmolFe 3 o 4 , continue stirring.

[0061] Weigh magnesium sulfate and SDBS with a molar ratio of 1:5 and dissolve them in water, add them into a three-necked flask, adjust the pH to 5, and continue stirring.

[0062] Raise the temperature to 70° C., add 0.1 mmol of dimethyl azobisisobutyrate as an initiator, put it into a microwave reactor and react at 400 W for 2 minutes.

[0063] After the microwave is completed, the solution is filtered to obtain a spherical polymer, and the cadmium ion is eluted with a nitric acid solution, shaken for 5 hours in a water bath at 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com