Soil stabilizer and preparation method and application thereof

A technology of soil curing agent and sodium chloride, which is applied in the direction of chemical instruments and methods, applications, soil conditioning materials, etc., can solve the problems of large dry shrinkage of cement soil, easy softening, and increased engineering costs, and achieves improved compressive strength, The preparation method is simple and the effect of solving application problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

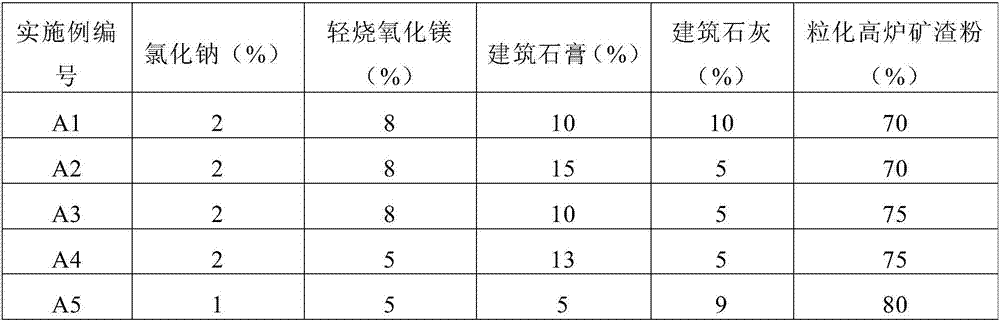

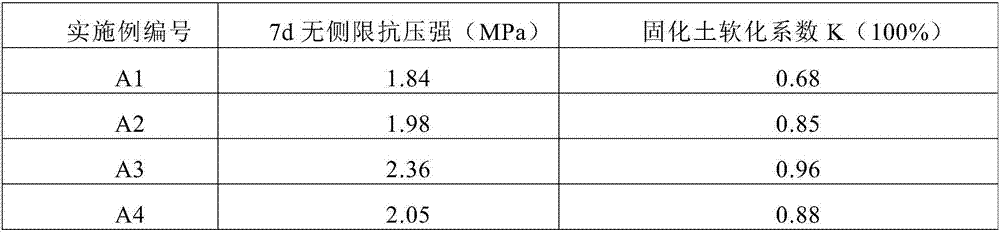

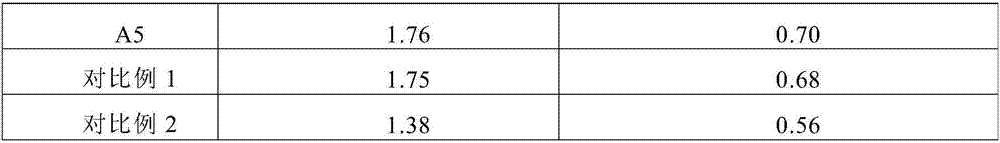

[0018] Example: Preparation of soil solidification agent

[0019] Put sodium chloride, light burnt magnesia, building gypsum, building lime, and granulated blast furnace slag powder into the mixing equipment according to the proportion, and mix them evenly. The content of each component is shown in Table 1.

[0020] Among them, the sodium chloride used in the embodiments is salt used for mining in seawater and lake salt or refined industrial salt made from salt lake brine, rock salt or underground brine, and the sodium chloride content is ≥92%. ≤2%, water insoluble matter ≤0.4%.

[0021] The light burnt magnesia used is the light burnt magnesia produced by calcining and grinding magnesite for magnesite products. The soil solidifying agent of the present invention uses lightly burned magnesia, with a magnesia content of 85%, of which, the content of active magnesia is 70%, the content of free magnesia is 1.0%, and the remaining 6% is sieve with 80μm square holes.

[0022] The "buildi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com