Waste lubricating oil treatment method

A technology for waste lubricating oil and treatment method, which is applied in the treatment of hydrocarbon oil, lubricating composition, petroleum industry, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

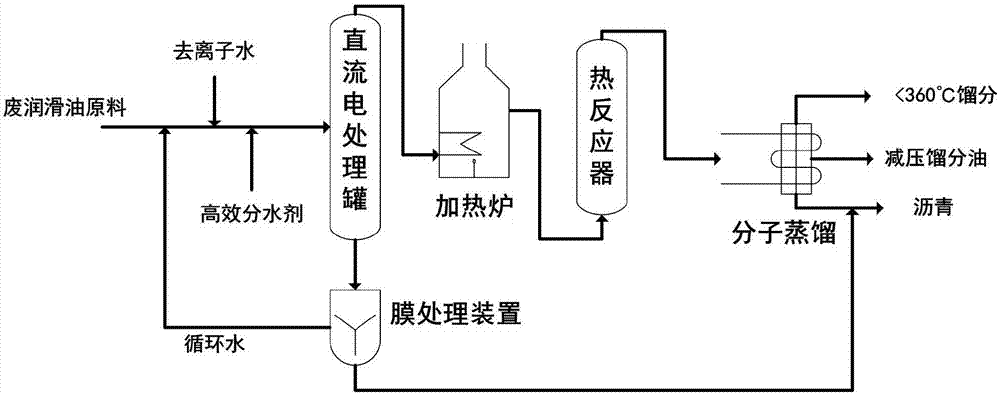

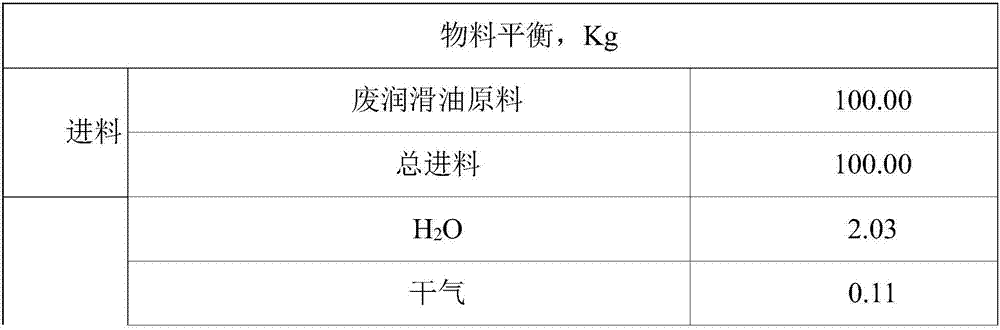

[0025] Waste lubricating oil processing method, comprises the following steps:

[0026] (1) Direct current treatment: After adding 8wt% deionized water and 20μg·g-1 water-separating agent (the water-separating agent is an ether compound) to the raw material of waste lubricating oil, it enters the direct current treatment tank. , stay at 100°C for 20 minutes to obtain upper layer oil and lower layer water;

[0027] (2) The lower water phase from the direct current treatment tank enters the membrane treatment unit, and the clean water can be recycled through nanofiltration membrane treatment and added to the waste lubricating oil, and the sludge is used as a raw material for asphalt production;

[0028] (3) The oil phase in the upper layer of the direct current treatment tank enters the moderate thermal conversion reactor, and reacts at 360°C and normal pressure for 80 minutes to obtain the product after thermal conversion;

[0029] ⑷The product after thermal conversion enters ...

Embodiment 2

[0031] Waste lubricating oil processing method, comprises the following steps:

[0032] (1) Direct current treatment: add 5wt% deionized water and 10 μg g-1 water-separating agent to the waste lubricating oil raw material (the water-separating agent is an equal mass mixture of polyoxyethylene alkyl alcohol ether and polyoxyethylene alkylamine) Finally, enter the direct current treatment tank, and stay for 50 minutes under the condition of direct current electric field strength of 500V / cm and temperature of 70°C to obtain the upper layer of oil and the lower layer of water;

[0033] (2) The lower water phase from the direct current treatment tank enters the membrane treatment unit, and the clean water can be recycled through nanofiltration membrane treatment and added to the waste lubricating oil, and the sludge is used as a raw material for asphalt production;

[0034] (3) The oil phase in the upper layer of the direct current treatment tank enters the moderate thermal convers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com