System and method for monitoring industrial waste gas discharge

A technology of industrial waste gas and supervision system, which is applied in general control system, control/regulation system, program control, etc., can solve problems such as insufficient enforcement, ineffective control of industrial waste gas discharge, and regulatory loopholes in environmental protection departments, etc., to achieve Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

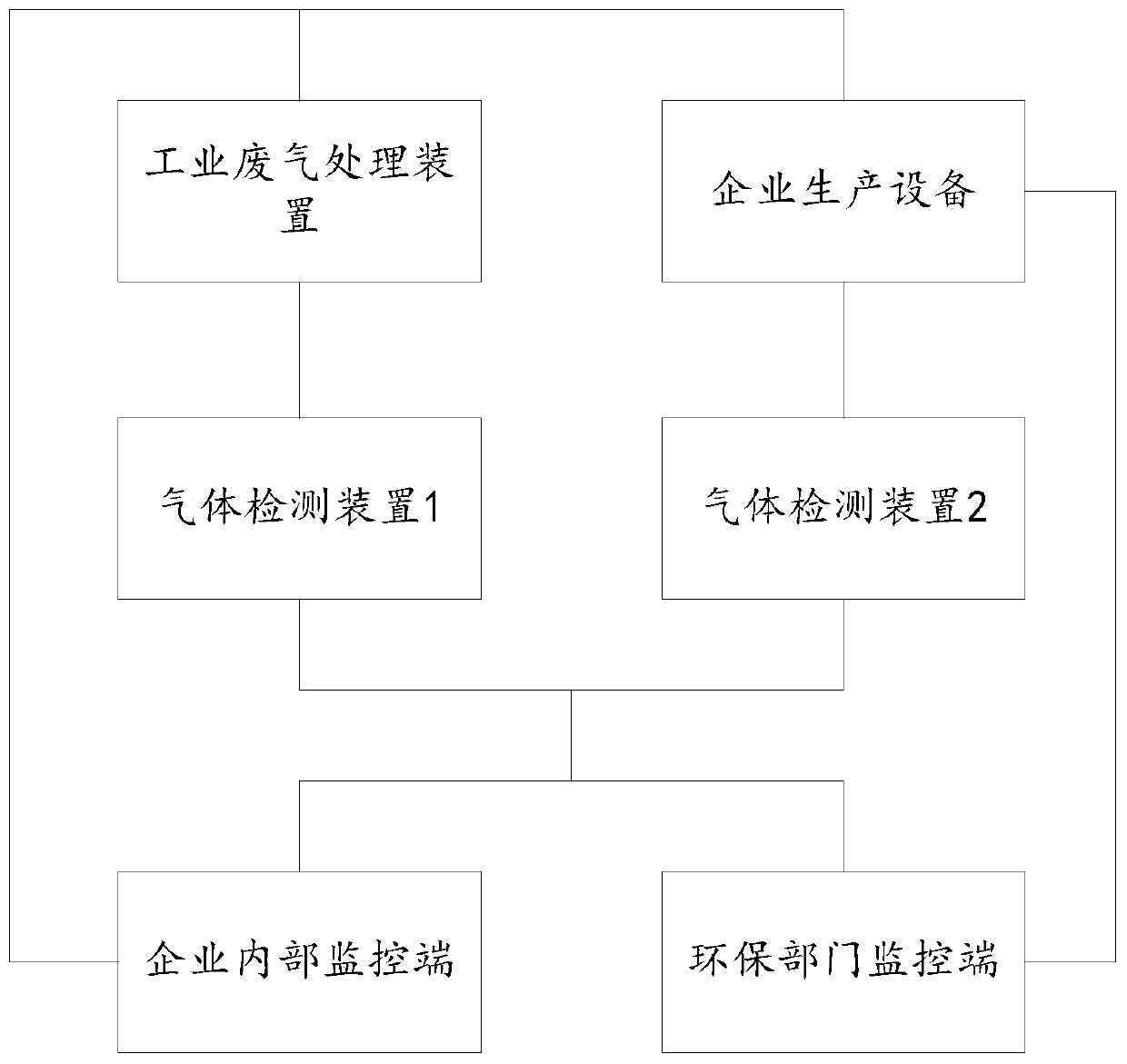

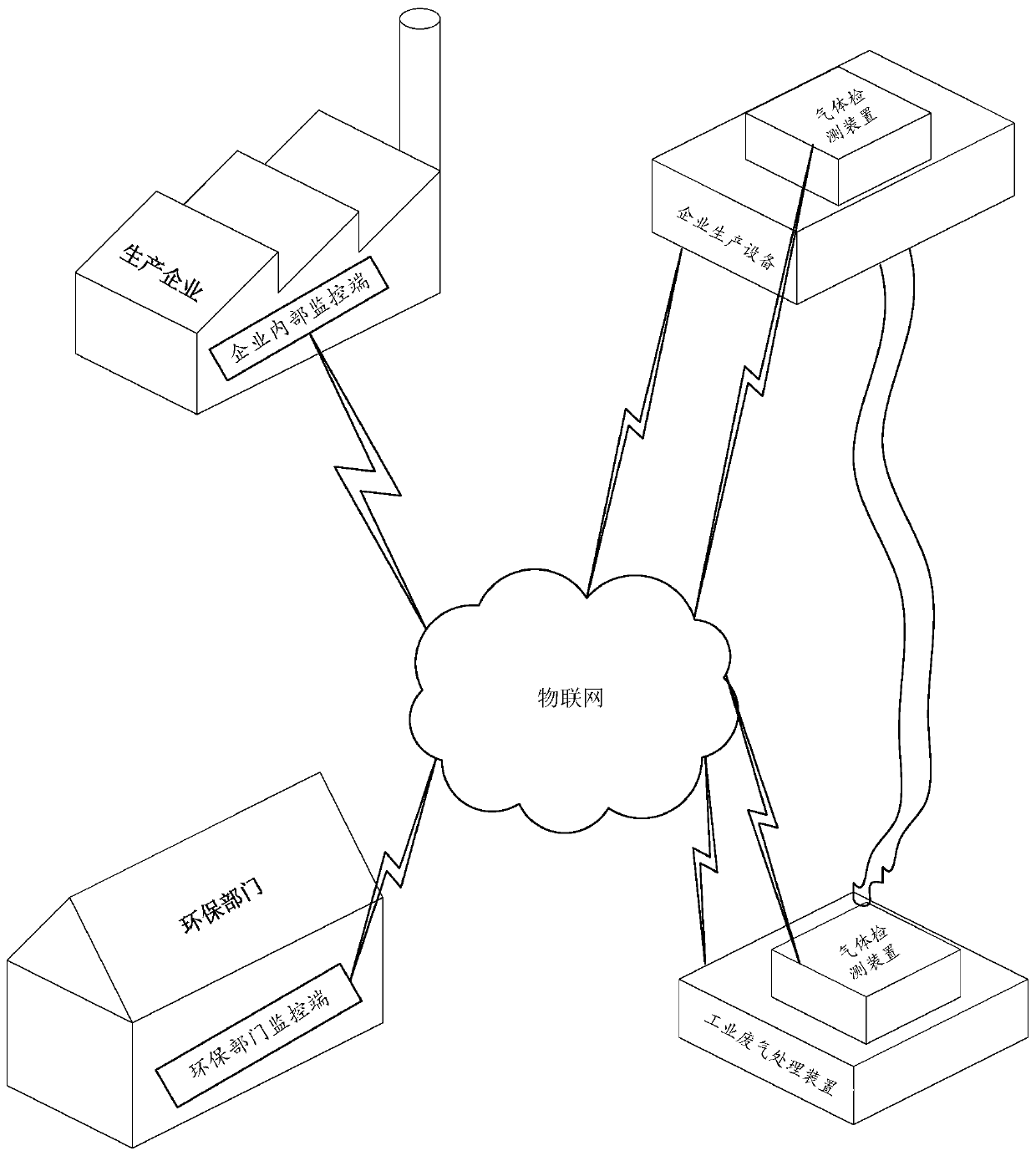

[0052] figure 1 This is a structural block diagram of an industrial waste gas emission monitoring system provided in Embodiment 1 of the present invention.

[0053] Specific as figure 1 As shown, an industrial waste gas emission monitoring system includes a gas detection device connected through the Internet of Things, an enterprise internal monitoring terminal and an environmental protection department monitoring terminal,

[0054] The gas detection device is used to detect the composition and concentration of industrial waste gas emitted by the production equipment and / or industrial waste gas treatment device of an enterprise, and obtain composition and concentration data of the industrial waste gas; and separate the composition and concentration data of the industrial waste gas Sent to the internal monitoring terminal of the enterprise and the monitoring terminal of the environmental protection department;

[0055] The internal monitoring terminal of the enterprise is used to dete...

Embodiment 2

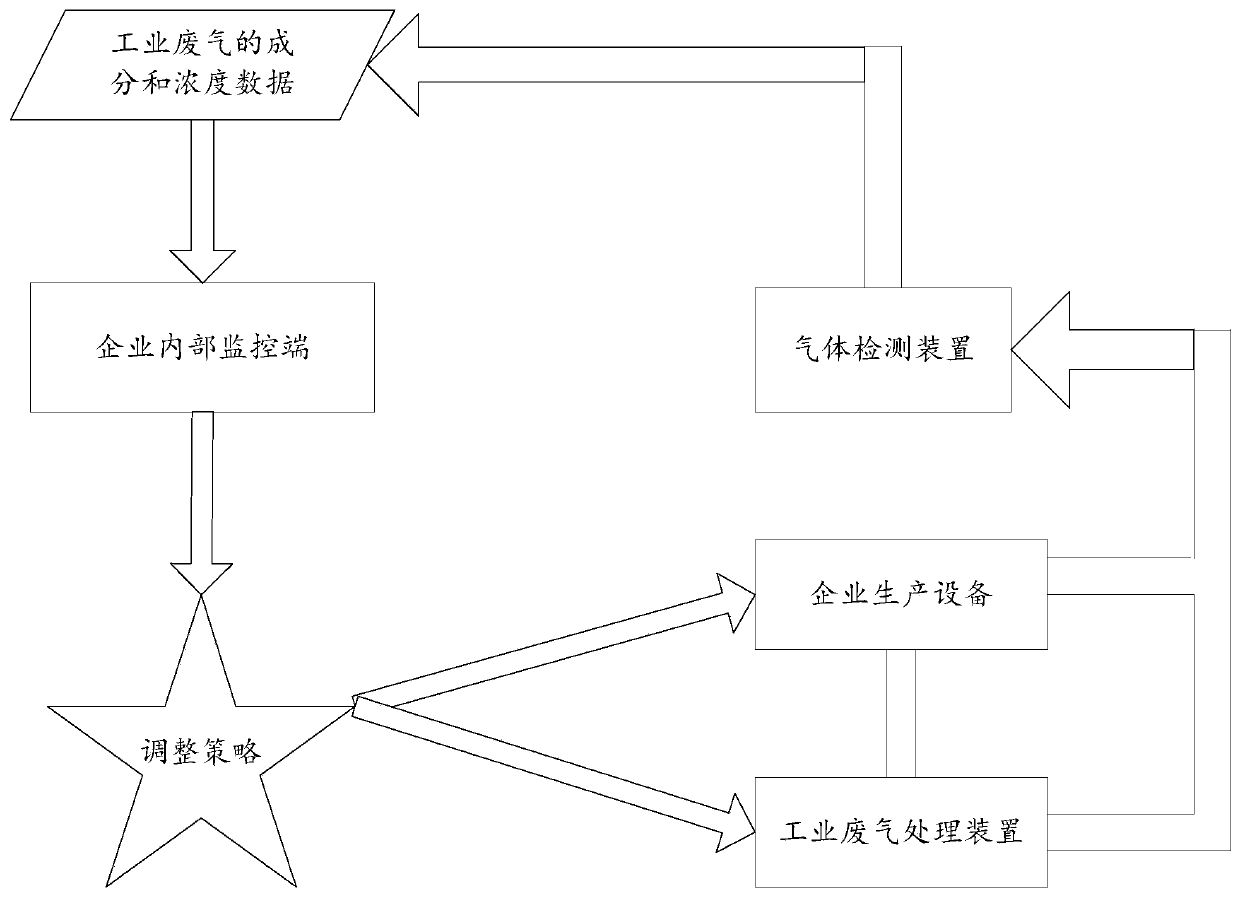

[0062] On the basis of the monitoring system for industrial waste gas emissions provided in the first embodiment of the present invention, the present invention also provides the second embodiment. image 3 This is a state diagram of the monitoring end of the enterprise's internal monitoring end of an industrial waste gas emission monitoring system provided in Embodiment 2 of the present invention. In Embodiment 2, such as image 3 As shown,

[0063] The internal monitoring terminal of the enterprise is also used to generate and adjust the adjustment strategy of the industrial waste gas emitted by the production equipment and / or industrial waste gas treatment device of the enterprise according to the composition and / or concentration data of the industrial waste gas, and adjust the adjustment strategy according to the adjustment strategy. The composition and / or concentration of industrial waste gas discharged from the production equipment of the enterprise; and / or the composition an...

Embodiment 3

[0066] On the basis of the monitoring system for industrial waste gas emissions provided in the second embodiment of the present invention, the present invention also provides the third embodiment. Figure 4 This is a state diagram of the interaction between the internal monitoring end of the enterprise and the monitoring end of the environmental protection department of an industrial waste gas emission monitoring system provided by Embodiment 3 of the present invention. In Embodiment 3, such as Figure 4 As shown,

[0067] After the monitoring terminal of the environmental protection department online controls the production equipment of the enterprise to stop production, the internal monitoring terminal of the enterprise is also used to send the adjustment strategy online to the monitoring terminal of the environmental protection department;

[0068] The environmental protection department monitoring terminal is also used to review the received adjustment strategy;

[0069] If the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com