Chinese magnoliavine fruit and guar gum composite film coating cherry tomato fresh-keeping agent and fresh keeping method

A technology of guar gum and cherry tomato, which is applied in the direction of protecting fruits/vegetables with a coating protective layer, keeping fruits and vegetables fresh, and using food ingredients as coating agents. Nutrients, effect of inhibiting respiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation and optimization of embodiment 1 composite coating preservative

[0026] 1.1 Preparation of plant extract mother liquor

[0027] Weigh 50.00g of cinnamon and crush it through 40 mesh, put it into a 1000mL beaker, add 250mL of absolute ethanol, place in a 60°C water bath for 1 hour, filter under reduced pressure, concentrate and recover the ethanol with a rotary evaporator, add 10mL of 50% ethanol to dissolve it ultrasonically, add water Set the volume to 100mL, that is, make the mother liquor of cinnamon extract with a mass volume concentration of 0.50g / mL, seal it, store it at 4°C for later use, and dilute to the corresponding concentration when used.

[0028] Weigh 30.00g of Ligustrum lucidum and Schisandra chinensis respectively, crush them through 40 meshes, put them into 1000mL beakers and add 150mL of water, soak for 2 hours with ultrasonic assistance, boil with electric furnace for 20 minutes, filter with sterile gauze, and centrifuge at 4000r / min for...

Embodiment 2 5

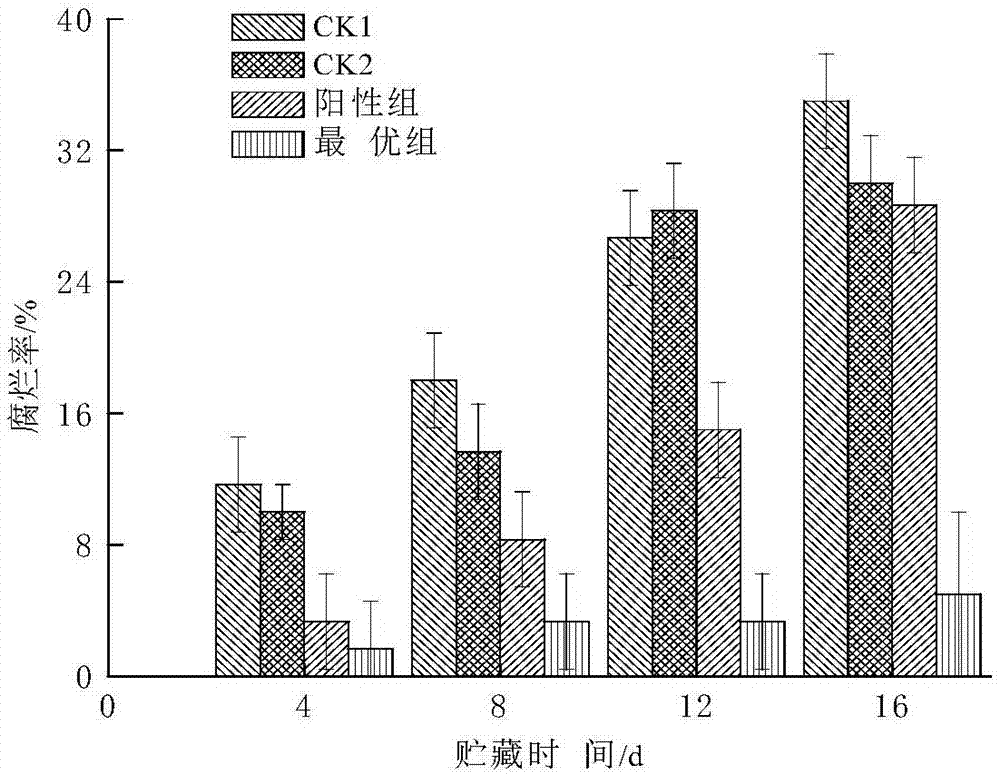

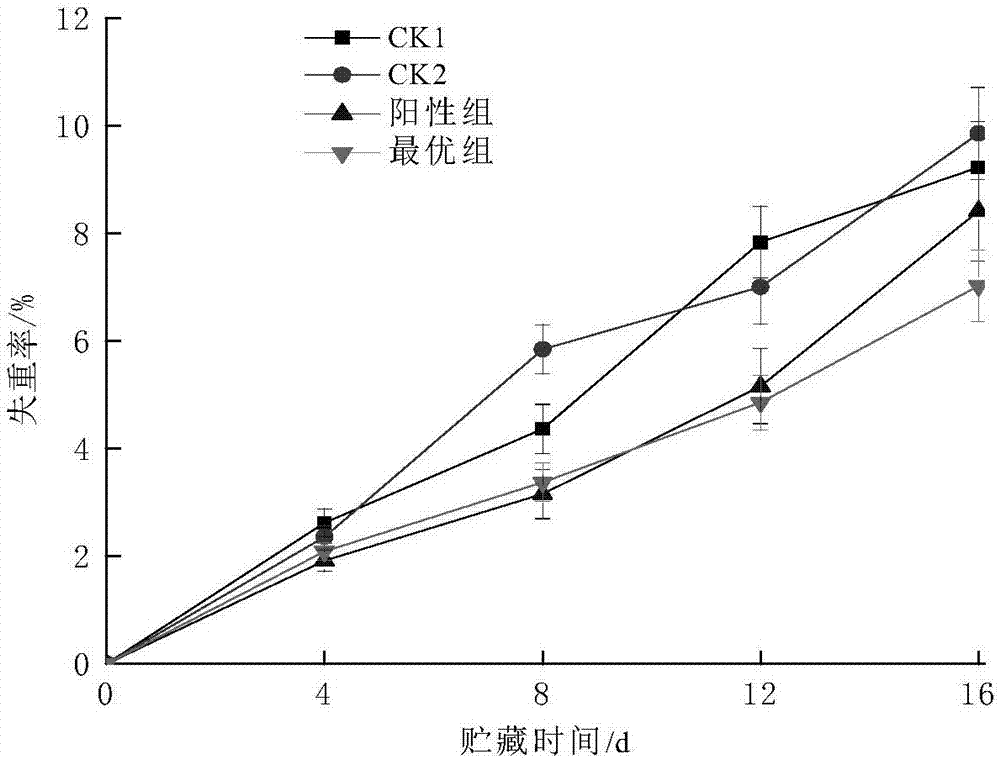

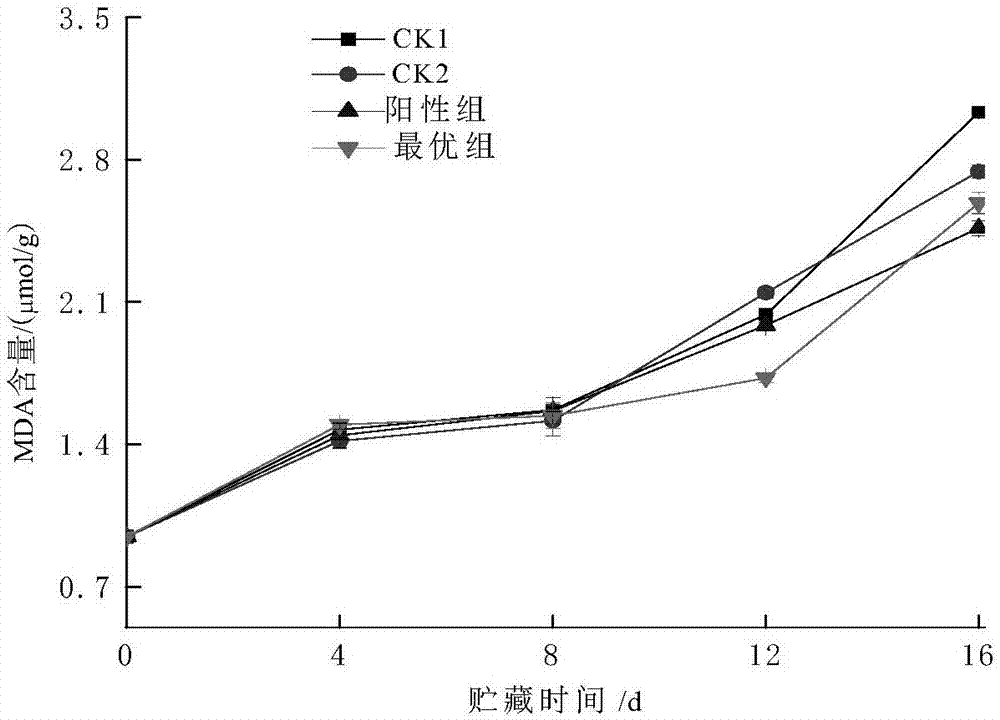

[0048] Example 2 Effect of Schisandra Fructus and Guar Gum Composite Coating Preservative on Postharvest Fresh-keeping Effect of Cherry Tomatoes

[0049] 2.1 Preparation of optimal composite coating preservative

[0050] Weigh 50.00g Schisandra chinensis and crush through 40 mesh, put it into a 1000mL beaker, add 200mL water, soak for 2 hours with ultrasonic assistance, filter with sterile gauze for 20 minutes after boiling in an electric stove, centrifuge at 4000r / min for 10 minutes, take the supernatant Make up to 100mL, and make 0.50g / mL schisandra extract mother liquor. Then weigh 4.75g of guar gum dry powder, put it into the mother liquor of Schisandra chinensis extract, add 300mL of water and 7.75mL of edible glycerin, put it in a water bath at 60°C and stir it with a booster electric mixer at high speed to make it fully mix and dissolve, and set the volume to 500mL , that is to make the optimal group composite coating film preservative (the mass volume concentration of...

Embodiment 3

[0071] Weigh 40.00g Schisandra chinensis and crush it through 40 meshes, put it into a 1000mL beaker, add 200mL water, soak for 2 hours with ultrasonic assistance, filter with sterile gauze for 20 minutes after boiling in an electric furnace, centrifuge at 4000r / min for 10 minutes, take the supernatant Make up to 100mL, and make 0.40g / mL schisandra extract mother liquor. Then weigh 4.25g of guar gum dry powder and put it into the mother liquor of Schisandra chinensis extract, then add 300mL of water and 7.00mL of edible glycerin, put it in a 60°C water bath and stir at a high speed with a booster electric mixer to make it fully mix and dissolve, and set the volume to 500mL, to get the composite coating preservative of the present invention, the Schisandra water extract mass volume concentration is 0.08g / mL in this preservative, the guar gum mass volume concentration is 0.0085g / mL, the edible glycerol volume concentration was 1.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com