Graphene/silica gel solid extraction material and application thereof

A solid-phase extraction material, graphene technology, applied in material separation, analysis of materials, other chemical processes and other directions, can solve the problems of narrow pH applicable range, cumbersome detection steps, reduced detection accuracy, etc., to improve detection accuracy, Good adsorption and stability, wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Preparation process of graphene colloidal solution

[0037] Dissolve 0.500g of graphene oxide with a particle size of less than 10 μm in 100ml of distilled water for 30 minutes, add 0.050g of PSS, stir and react at room temperature for 60 minutes, then 1.25mL of hydrazine hydrate (80%) is added to the above-mentioned graphene oxide colloidal aqueous solution, and then the whole The reaction system was placed in an oil bath at 100° C. for reflux reaction for 24 hours to prepare a graphene colloid solution.

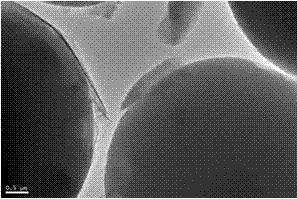

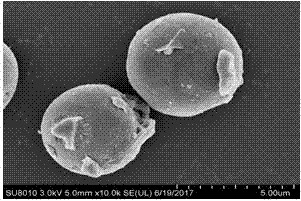

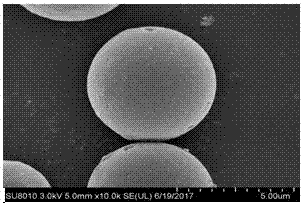

[0038] 2) Preparation process of graphene silica gel solid phase extraction material

[0039] Add 0.250g of amino silica gel with a particle size of 2-6μm into 100ml of distilled water, ultrasonically disperse for 30min, adjust the pH of the solution to about 3 with dilute hydrochloric acid (0.1mol / L), add 25ml of graphene colloid solution (5.0mg / ml ) into the amino silica gel suspension, and the mixed solution was reacted in a water bath shaker at 50°C for 5h to...

Embodiment 2

[0041] 1) Preparation process of graphene colloidal solution

[0042] Dissolve 1.000g of graphene oxide with a particle size of less than 10 μm in 100ml of distilled water for 30 minutes, add 0.100g of PSS, stir and react at room temperature for 60 minutes, then 1.25mL of hydrazine hydrate (80%) is added to the above graphene oxide colloidal aqueous solution, and then the whole The reaction system was placed in an oil bath at 100° C. for reflux reaction for 24 hours to prepare a graphene colloid solution.

[0043] 2) Preparation process of graphene silica gel solid phase extraction material

[0044]Add 0.500g of amino silica gel with a particle size of 2-6μm to 100ml of distilled water, ultrasonically disperse for 30min, adjust the pH of the solution to 2 with dilute hydrochloric acid (0.1mol / L), add 50ml of graphene colloid solution (10.0mg / ml) Into the amino silica gel suspension, the mixed solution was reacted in a water bath shaker at 50°C for 5h to ensure that they were ...

Embodiment 3

[0046] 1) Preparation process of graphene colloidal solution

[0047] Dissolve 2.000 g of graphene oxide with a particle size of 10-20 μm in 100 ml of distilled water and ultrasonically for 30 min, add 0.200 g of PSS, stir and react at room temperature for 60 min, then 1.25 mL of hydrazine hydrate (80%) is added to the above graphene oxide colloidal aqueous solution, Then whole reaction system was placed in 100 DEG C of oil baths and reflux reaction prepared graphene colloid solution after 24 hours.

[0048] 2) Preparation process of graphene silica gel solid phase extraction material

[0049] Add 1.000g of amino silica gel with a particle size of 5-10μm to 100ml of distilled water, ultrasonically disperse for 30min, adjust the pH of the solution to 4 with dilute hydrochloric acid (0.1mol / L), add 100ml of graphene colloid solution (20mg / ml) to In the amino silica gel suspension, the mixed solution was reacted in a water bath shaker at 50°C for 5h to ensure that they were comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com