Light source module based on LCD light-curing 3D printer

A 3D printer, light source module technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of poor consistency, permanent failure, junction temperature increase, etc., to improve the uniformity of light intensity and prolong the use. Life, the effect of increasing the light intensity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

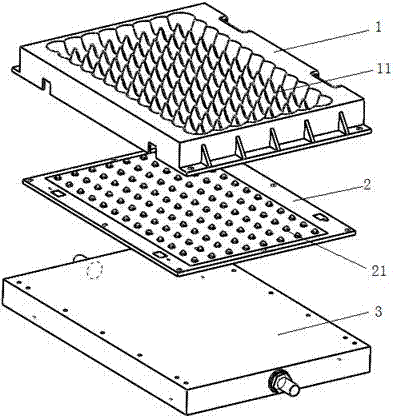

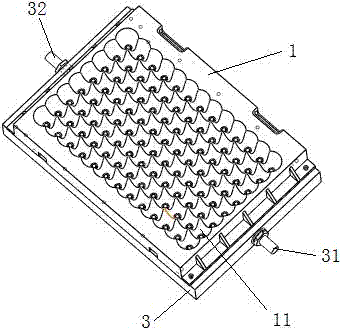

[0019] Such as Figure 1-2 A light source module based on an LCD light-curing 3D printer is shown, including a reflector 1, an LED lamp panel 2, and a cold water panel 3 fixedly arranged sequentially from top to bottom. The reflector 1 is provided with several reflectors distributed in a rectangular array. In the groove 11, several LED lamp beads 21 are fixedly arranged in a rectangular array on the LED lamp board 2, and the number of the LED lamp beads 21 is equal to that of the reflective groove 11, and they are in one-to-one correspondence. The reflector 1 is made of high-temperature-resistant plastic, and the surface is electroplated to improve the reflectivity; the cold water plate 3 is made of aluminum alloy with low price and high thermal conductivity.

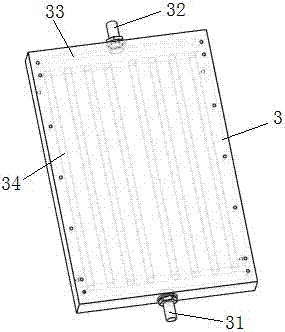

[0020] Such as image 3 As shown, water inlet 31 and water outlet 32 are respectively provided on the left and right sides of cold water plate 3, and water tank 33 is fixedly arranged inside the cold water plate posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com