Preparation method of single-layer graphene single molecule junction with mechanically controllable nanometer gap

A single-layer graphene, nano-gap technology, applied in the fields of chemistry, molecular electronics, and nanomaterials, can solve the problems of consuming manpower, material and financial resources, the results may not be achieved, and the success rate is low, achieving good stability and The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

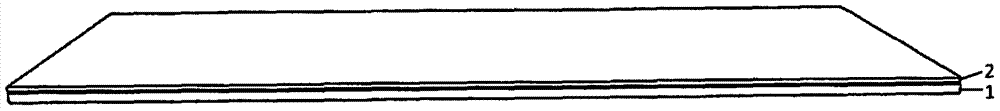

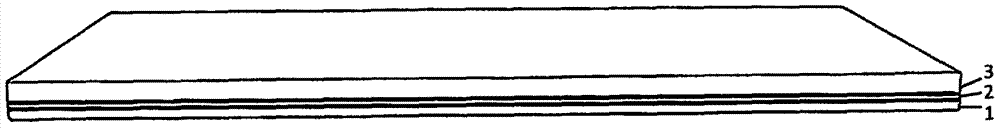

[0025] A copper foil (1) with a length of 44mm, a width of 12mm, and a thickness of about 50μm is used as a substrate, and a single-layer graphene (2) is grown by CVD; SiO is prepared on a copper sheet (5) 2 (4) Coating: add a certain amount of silicic acid (SiO 2 xH2O), constant temperature magnetic stirring at room temperature, to obtain SiO 2 Saturated fluorosilicic acid solution; take a certain volume of saturated solution, add deionized water, stir at a constant temperature and magnetic force for a period of time at 30°C, and prepare SiO with a certain concentration of fluorosilicic acid 2 supersaturated solution, that is, the preparation of SiO 2 Film growth solution; put the cleaned copper substrate into a beaker. After a certain period of time, take out the sample piece, dry it with a fan, and place it in a desiccator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com