Preparation method of hydroxylated graphene

A technology of hydroxylated graphene and graphene, which is applied in the field of graphene, can solve the problems of non-unique functional groups and the inability to obtain high-purity hydroxylated graphene, and achieve the effect of method safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Graphite oxide preparation, method is the same as embodiment 1.

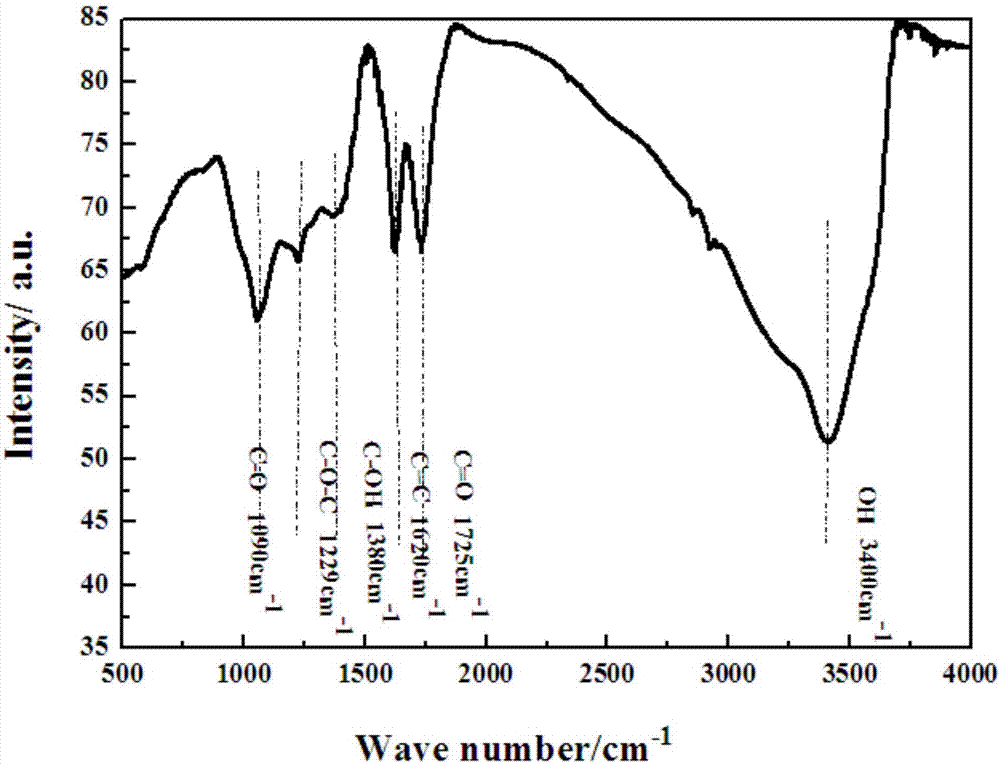

[0033] 2) Graphene oxide is prepared, the method is the same as in Example 1, the frequency of the ultrasonic stripping device is controlled at 18000Hz, the stripping time is 1.0h, the stripping temperature is controlled at 30°C, the oxygen content of the prepared graphene oxide is 40at%, and the infrared Spectral graph such as figure 1 shown.

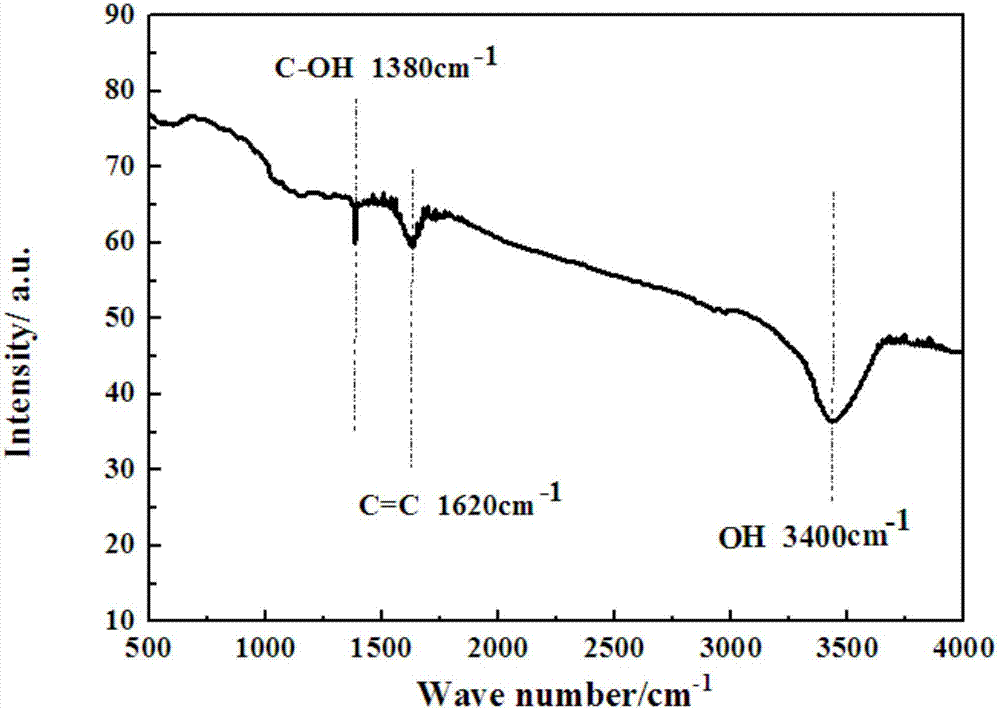

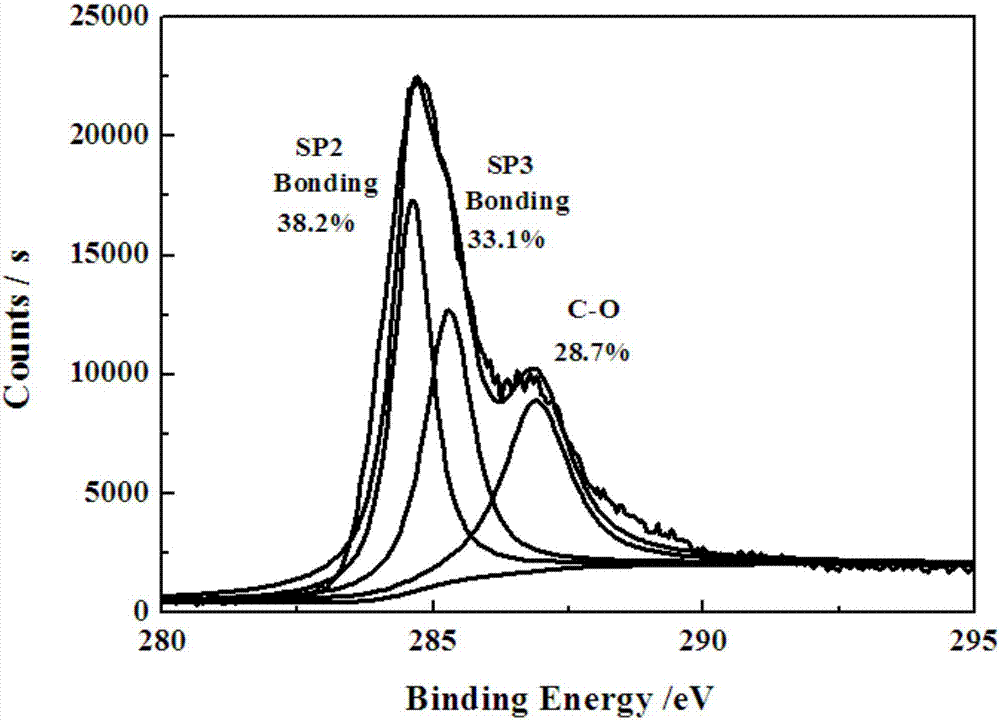

[0034] 3) Preparation of hydroxylated graphene

[0035] Introduce a mixed gas of helium and nitrogen at a volume ratio of 1:1 into the constant temperature chamber for 30 minutes. After the air is removed from the entire space, the temperature is raised to 300°C. After the temperature is constant, graphene oxide is introduced into the chamber. The heat treatment time is 60min, the obtained graphene. The infrared spectrum of hydroxylated graphene is as follows figure 2 As shown, the C1s peak spectrum is as follows image 3 As shown, the SEM image as Figu...

Embodiment 2

[0037] 1) Graphite oxide preparation, method is the same as embodiment 1.

[0038] 2) Graphene oxide preparation, the method is the same as in Example 1, the frequency of the ultrasonic stripping device is controlled at 10000 Hz, the stripping time is 2.0 h, the stripping temperature is controlled at 40 ° C, and the oxygen content of the prepared graphene oxide is 35 at%.

[0039] 3) Preparation of hydroxylated graphene

[0040] Put the mixed gas of argon and nitrogen at a volume ratio of 1:1 into the constant temperature cabin for 30 minutes. After the air is removed from the entire space, the temperature is raised to 300 ° C. After the temperature is constant, the graphene oxide is passed into the cabin, and the heat treatment time is 15 minutes respectively. , 30min, 45min, the obtained graphene is analyzed by IR, XPS, EDS.

Embodiment 3

[0042] 1) Graphite oxide preparation, method is the same as embodiment 1.

[0043] 2) Graphene oxide preparation, the method is the same as in Example 1, the frequency of the ultrasonic stripping device is controlled at 20000 Hz, the stripping time is 0.5h, the stripping temperature is controlled at 45° C., and the oxygen content of the prepared graphene oxide is 45 at%.

[0044] 3) Preparation of hydroxylated graphene

[0045] Inject a mixture of inert gas (argon, neon) and nitrogen in a volume ratio of 1:1 into the constant temperature chamber for 30 minutes. After the air is removed from the entire space, the temperature is raised to 250°C. After the temperature is constant, the graphene oxide is passed through In the cabin, the heat treatment time is 15min, 30min, 45min, and 60min respectively, and the obtained graphene is analyzed by IR, XPS, and EDS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com