Gelatin-polylactic acid grafted amphipathic copolymer nano-micelle material and preparation method thereof

A technology of amphiphilic copolymer and graft copolymer, which is applied in the field of gelatin-polylactic acid grafted amphiphilic copolymer nanomicelle material and its preparation, can solve problems such as damage to biological cells, and achieves reduction of dosage, reduction of damage, The effect of reducing the positive charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take gelatin (the number average molecular weight is 1.2×10 4 ) 2g, lactide 8g (feeding ratio is 1:4) in a three-necked flask, vacuum for one hour, add 40mL dimethyl sulfoxide to dissolve, and ensure the nitrogen environment, heat the oil bath to 85 ° C, wait for the raw materials to dissolve After completion, add 40 μL of stannous octoate, and stir and react at 85°C for 24 hours under nitrogen protection to obtain a gelatin-polylactic acid graft copolymer reaction solution; the reaction solution is precipitated with distilled water to remove reactants that do not participate in the reaction, polylactic acid homogeneous polymer, the above solution was transferred to a dialysis bag for dialysis for 3 days, and after the dialysis was completed, it was freeze-dried to obtain a solid product.

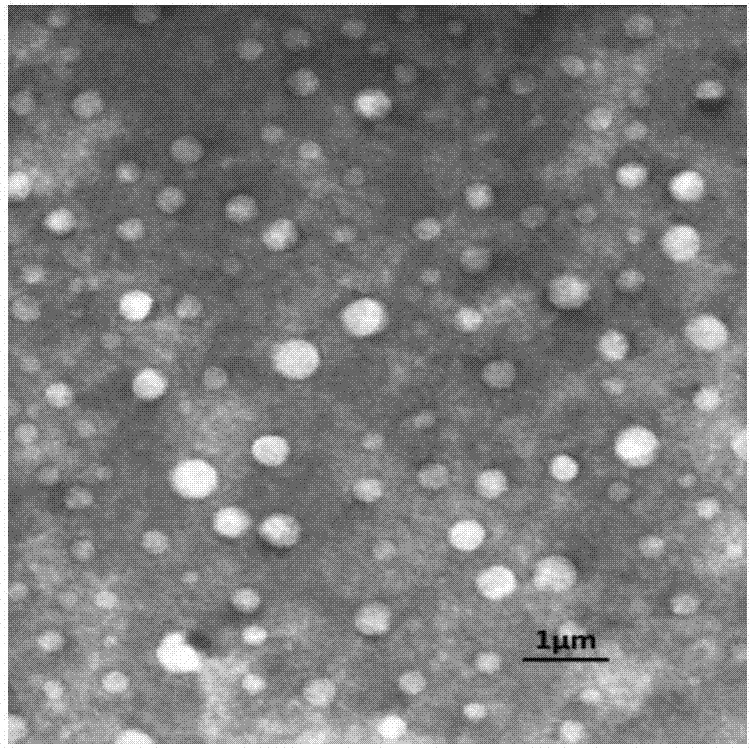

[0036] TEM image of Gel-g-PLLA nanomicelle ( figure 1 shown), showing that the nanomicelles are uniformly spherical.

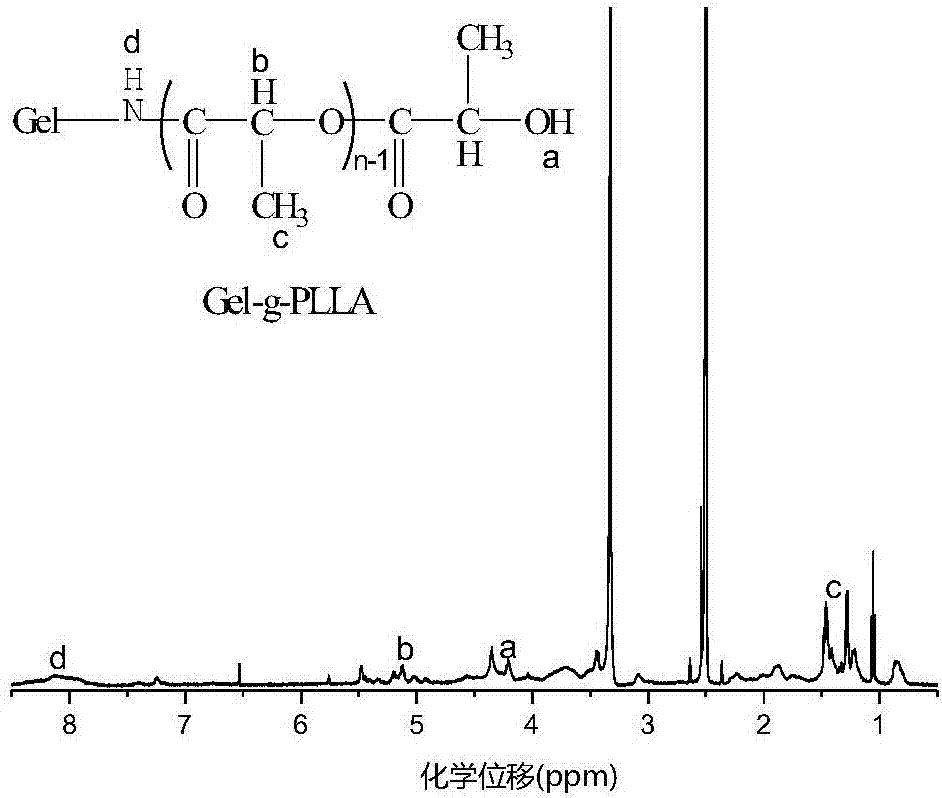

[0037] 1 HNMR spectrum ( figure 2 Shown) is a liquid nucle...

Embodiment 2

[0043] Take gelatin (the number average molecular weight is 1.2×10 4 ) 2g, lactide 16g (feeding ratio: 1:8) in a three-necked flask, vacuumize for one hour, add 40mL dimethyl sulfoxide to dissolve, and ensure the nitrogen environment, heat the oil bath to 85°C, and wait for the raw materials to dissolve After completion, add 72 μL of stannous octoate, and stir and react at 85°C for 24 hours under nitrogen protection to obtain a gelatin-polylactic acid graft copolymer reaction solution; the reaction solution is precipitated with distilled water to remove reactants that do not participate in the reaction, polylactic acid homogeneous polymer, the above solution was transferred to a dialysis bag for dialysis for 3 days, and after the dialysis was completed, it was freeze-dried to obtain a solid product.

Embodiment 3

[0045] Take gelatin (the number average molecular weight is 1.2×10 4 ) 2g, lactide 20g (feeding ratio is 1:10) in a three-necked flask, vacuumize for one hour, add 40mL dimethyl sulfoxide to dissolve, and ensure the nitrogen environment, heat the oil bath to 85°C, and wait for the raw materials to dissolve After completion, add 88 μL of stannous octoate, and stir and react at 85°C for 24 hours under nitrogen protection to obtain a gelatin-polylactic acid graft copolymer reaction solution; the reaction solution is precipitated with distilled water to remove unreacted reactants, polylactic acid, and polymer, the above solution was transferred to a dialysis bag for dialysis for 3 days, and after the dialysis was completed, it was freeze-dried to obtain a solid product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com