Tire pyrolysis oil fraction fixed bed hydro-upgrading catalysis process

A tire pyrolysis oil, hydrogenation modification technology, applied in the direction of hydrogenation treatment process, petroleum industry, hydrogenation refining of aromatic hydrocarbons, etc., can solve the problems of unfavorable miniaturization operation production, complicated process flow, large investment, etc., and achieve the product The modification effect is obvious, the economic and environmental benefits are large, and the effect of content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

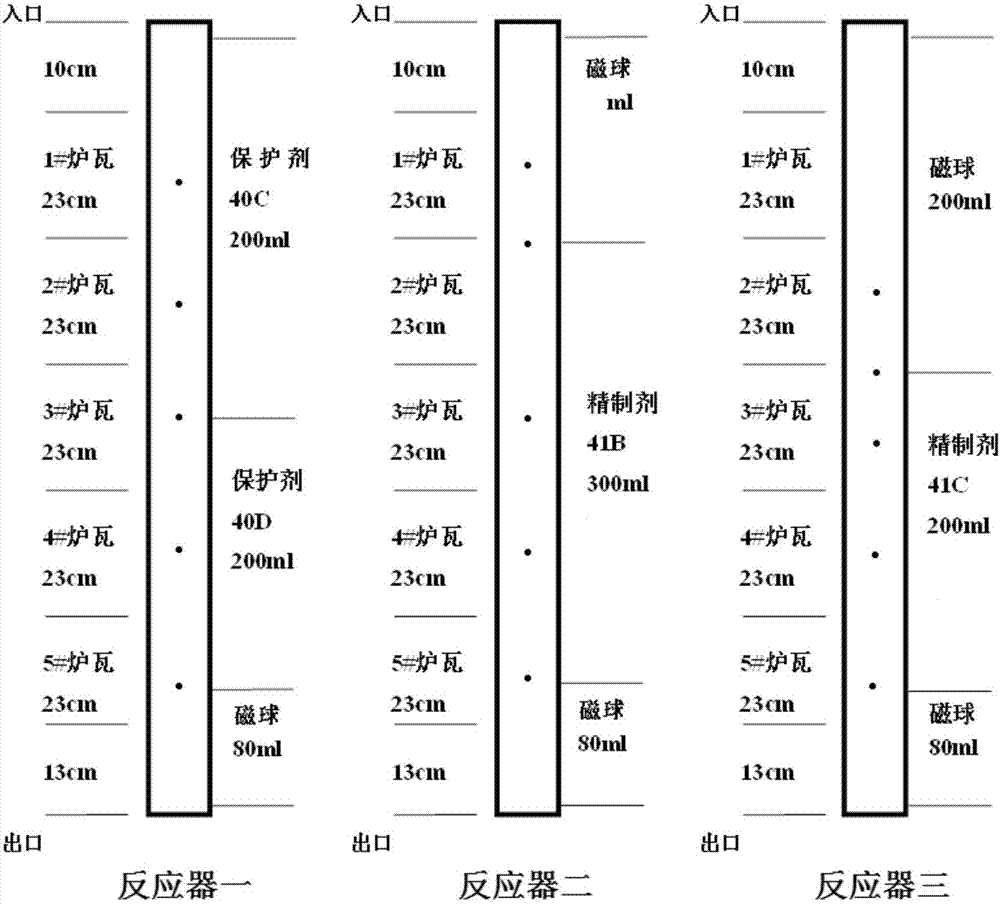

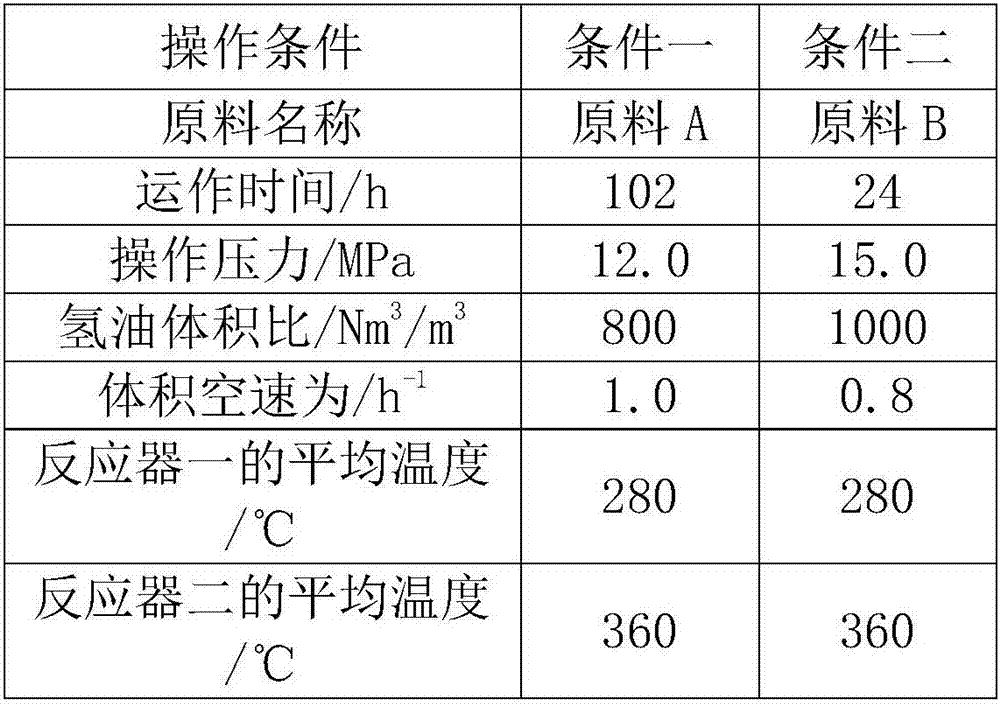

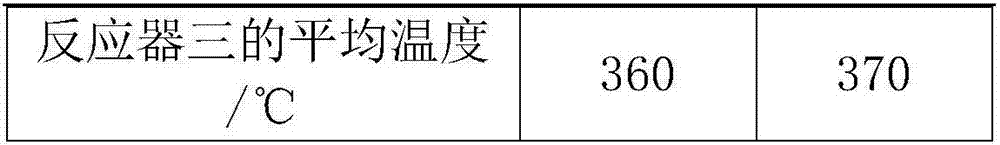

[0032] A tire cracking oil distillate fixed bed hydrogenation upgrading catalytic process, including a reaction device for upgrading raw material oil formed by connecting the first, second and third reactors in series, and the raw material oil is gasoline of tire cracking oil When with the stock oil A of the diesel fraction, the gasoline and diesel mass ratio in the stock oil A is 1:(1.5-4.5), and the gasoline and the diesel mass ratio in the stock oil A of the present invention are preferably 1:2. The inner diameter of the first, second and third reactors is 24mm, the height is 1380mm, the outer diameter of the thermocouple casing is 9.5mm, and the average cross-sectional area of the reactor is 381.5mm 2 , the first, second and third reactors are continuously heated by 5 furnace tiles installed in the heater, each furnace tile is 23cm high, and the total height is 115cm. The distance between the reactor inlet and the first furnace tile is 10cm, and the fifth furnace tile Th...

Embodiment 2

[0042] A tire cracking oil distillate fixed bed hydrogenation upgrading catalytic process, including a reaction device for upgrading raw material oil formed by connecting the first, second and third reactors in series, and the raw material oil is gasoline of tire cracking oil , diesel oil and the stock oil B of wax oil fraction, the mass ratio of the gasoline in stock oil B, diesel oil and wax oil is 1:(1.5-3.5):(1.5-3.5), in the stock oil B of the preferred present invention The mass ratio of gasoline, diesel and wax oil is 1:2:1.8. The inner diameter of the first, second and third reactors is 26mm, the height is 1380mm, the outer diameter of the thermocouple casing is 9.5mm, and the average cross-sectional area of the reactor is 381.5mm 2 , the first, second and third reactors are continuously heated by 5 furnace tiles installed in the heater, each furnace tile is 23cm high, and the total height is 115cm. The distance between the reactor inlet and the first furnace tile is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com