Purifying method for inhibiting degradation of mechanical sensing protein PDLIM3

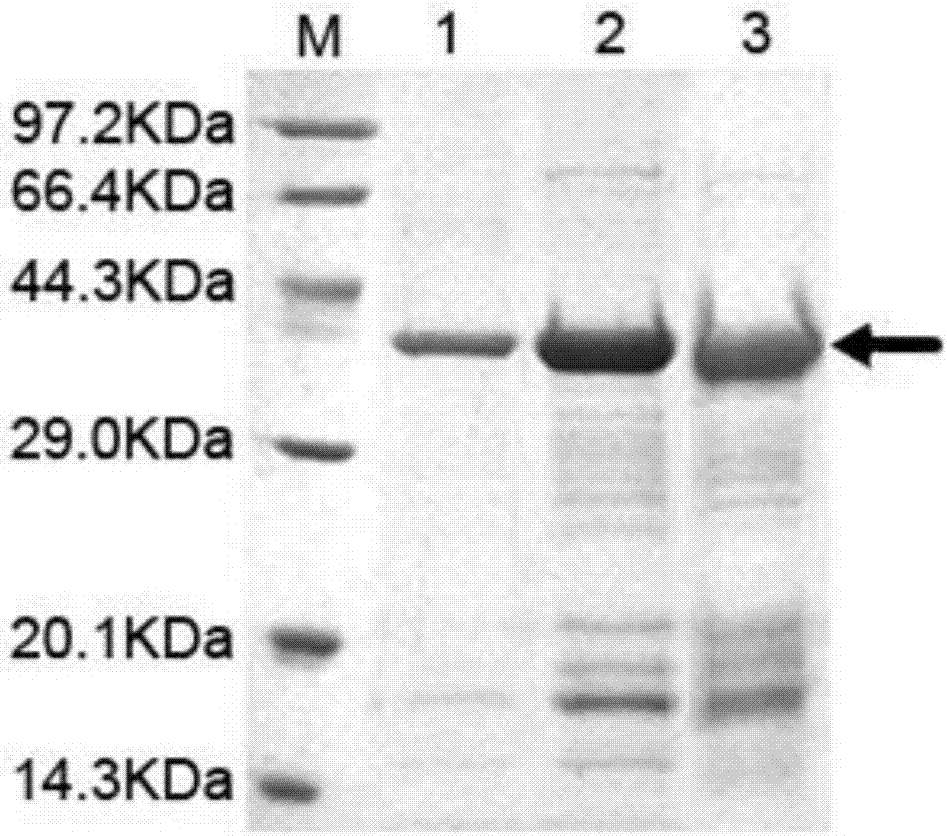

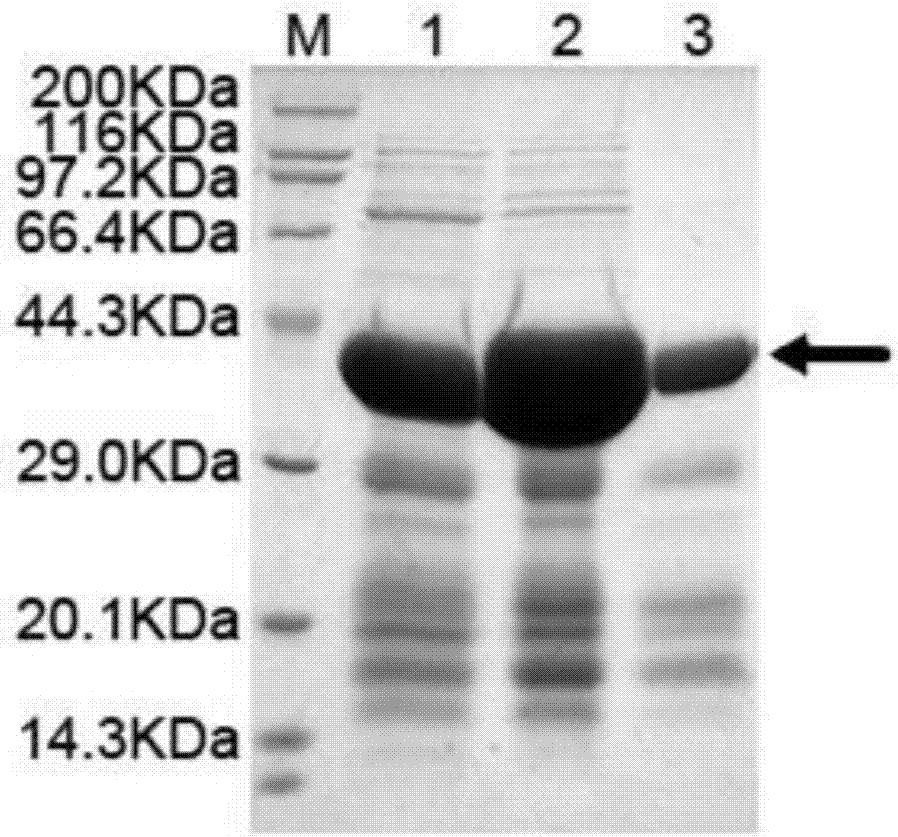

A purification method and protein technology, which is applied in the field of crystallization and protein purification, can solve the problems of serious degradation, low purity, and low activity, and achieve the effects of reducing time, improving concentration efficiency, and shortening concentration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

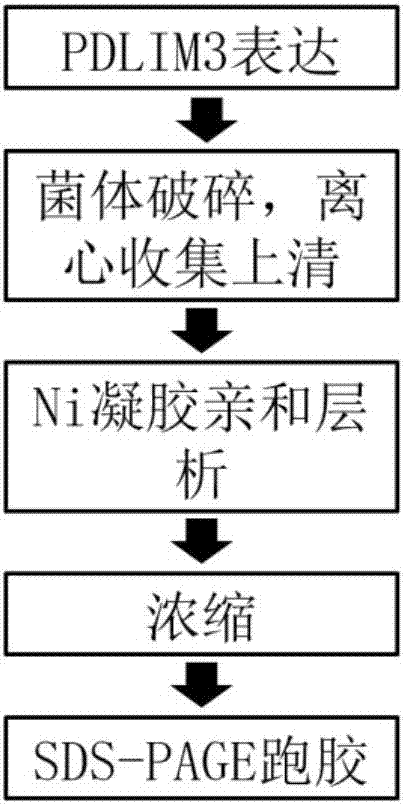

[0019] Concrete technical scheme step of the present invention is as follows:

[0020] The first step is to express the mechanosensory protein PDLIM3;

[0021] Inoculate the expression strain in 100-1000mL LB medium and cultivate to OD 600 When the value reaches 0.4-0.8, add a molar concentration of 1M IPTG mother solution to a final molar concentration of 0.2-0.8mM, and continue to cultivate for 3-8h. Centrifuge the bacterial liquid at 1000-4000 rpm for 10-30 min at a temperature of 0-4°C, discard the supernatant, and collect the bacterial cells.

[0022] In the second step, the bacteria are broken, and the supernatant is collected by centrifugation;

[0023] Prepare a lysate with a molar concentration of 50mM Tris-HCl, 50mM NaCl, and pH 8.0, and resuspend the cells wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com