Preparation method of high-strength ferromagnetism-free texture Ni-W alloy base band

A ferromagnetic, high-strength technology, applied in the field of textured metal basebands for high-temperature coated superconductors, can solve the problems of no mass production, increased mechanical properties of the baseband, and long processes, and achieves suppression of growth, magnetic properties and mechanical properties. The performance is coordinated and unified, and the effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The steps of the preparation method of the embodiment of the present invention 1 are as follows:

[0033] First, vacuum induction melting is used to obtain nickel-tungsten alloy ingots with a tungsten atomic percentage of 17%, and then the obtained nickel-tungsten alloy ingots are used as raw materials, and then the initial alloy ingots are obtained through continuous casting and rolling processes;

[0034] The initial alloy billet obtained above is subjected to solution treatment, the process is: heat the heat treatment furnace to 1480 ° C, and then quickly put the sample into the heating zone for 10 minutes and then quench; the heating zone is the heat treatment furnace;

[0035] Remove the scale from the alloy ingot obtained above, and then cold-roll it to a thickness of 150 μm, with a cold-rolling deformation of 80%, to obtain a nickel-tungsten alloy cold-rolled base strip;

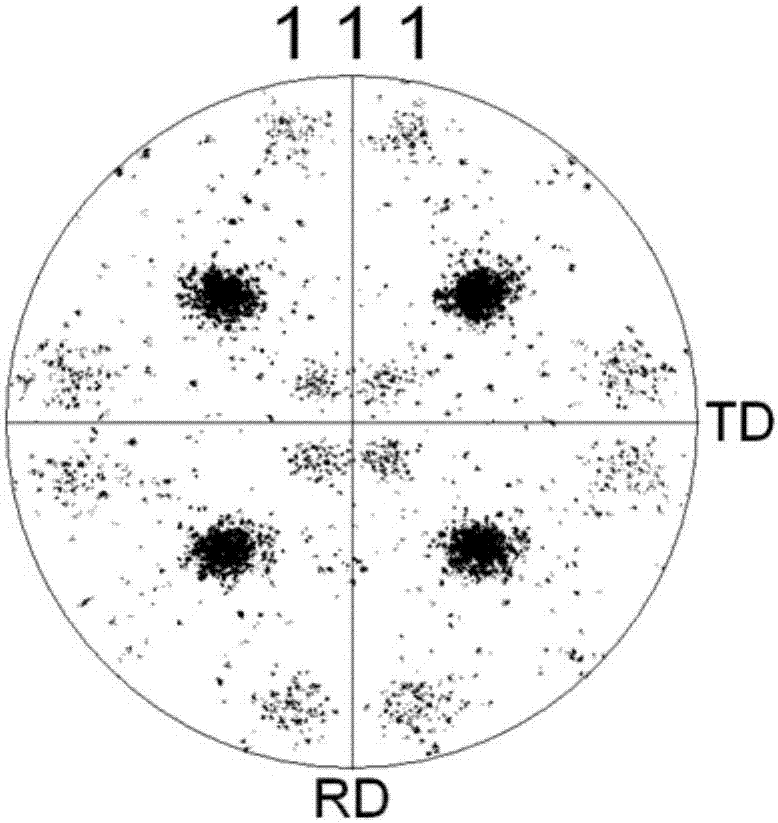

[0036] The nickel-tungsten alloy cold-rolled base strip obtained above is subjected to agin...

Embodiment 2

[0040] The steps of the preparation method of the embodiment of the present invention 2 are as follows:

[0041] First, vacuum induction melting is used to obtain nickel-tungsten alloy ingots with a tungsten atomic percentage of 19%, and then the obtained nickel-tungsten alloy ingots are used as raw materials, and then the initial alloy ingots are obtained through continuous casting and rolling processes;

[0042] The initial alloy billet obtained above is subjected to solution treatment, the process is: heat the heat treatment furnace to 1480 ° C, and then quickly put the sample into the heating zone for 10 minutes and then quench;

[0043] Remove the scale from the alloy ingot obtained above, and then cold-roll it to a thickness of 100 μm, with a cold-rolling deformation of 83%, to obtain a nickel-tungsten alloy cold-rolled base strip;

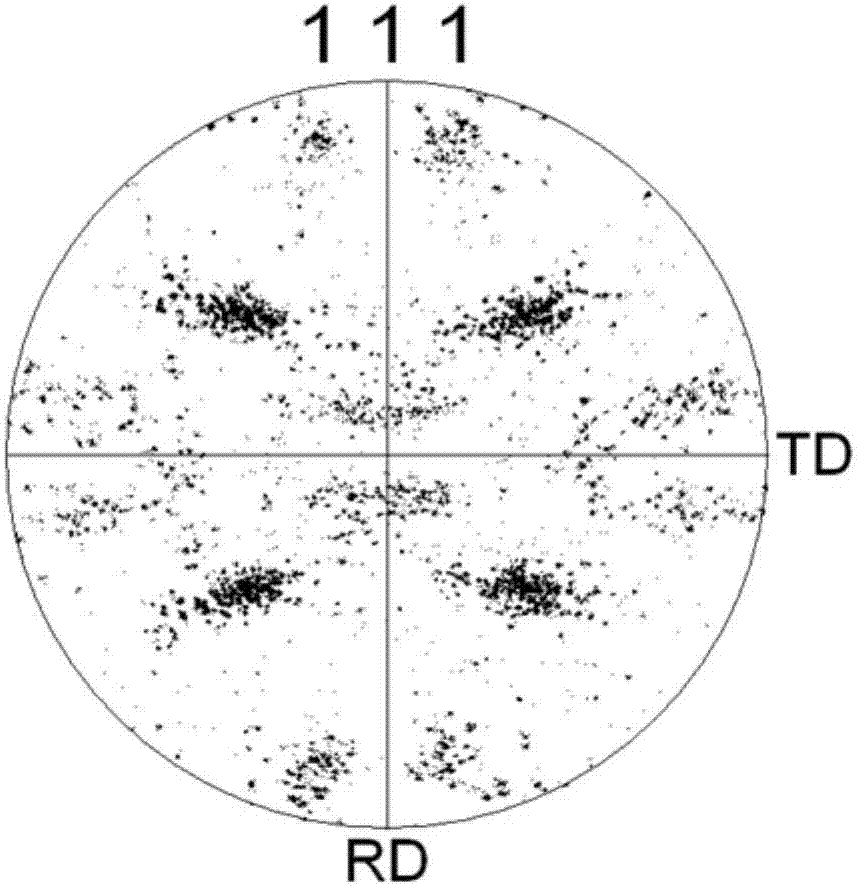

[0044] The nickel-tungsten alloy cold-rolled base strip obtained above is subjected to aging heat treatment. The process is as follows: hea...

Embodiment 3

[0048] The steps of the preparation method of the embodiment of the present invention 3 are as follows:

[0049] First, vacuum induction melting is used to obtain a nickel-tungsten alloy ingot with an atomic percentage of tungsten of 22%, and then the obtained nickel-tungsten alloy ingot is used as a raw material, and then the initial alloy billet is obtained through a continuous casting and rolling process;

[0050] The initial alloy billet obtained above is subjected to solution treatment, the process is: heat the heat treatment furnace to 1480 ° C, and then quickly put the sample into the heating zone for 10 minutes and then quench;

[0051] Remove the scale from the alloy billet obtained above, and then cold-roll it to a thickness of 150 μm, with a cold-rolling deformation of 77%, to obtain a nickel-tungsten alloy cold-rolled base strip;

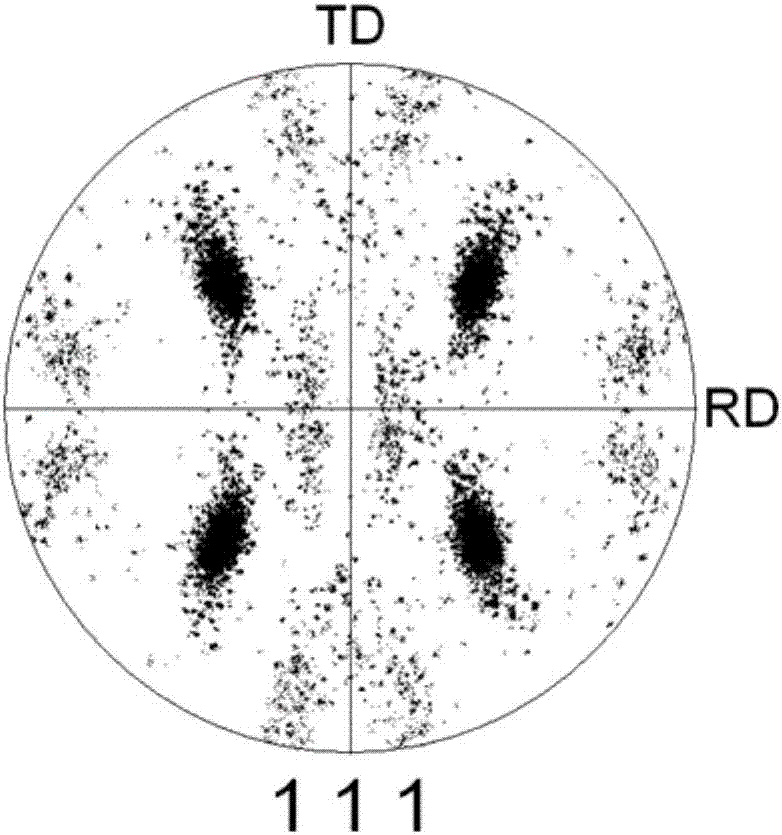

[0052]The nickel-tungsten alloy cold-rolled base strip obtained above is subjected to aging heat treatment. The process is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com