Artificial synthesis method for gem-quality colorless diamond

An artificial synthesis, diamond technology, applied in chemical instruments and methods, single crystal growth, polycrystalline material growth and other directions, can solve the problems of large influence of synthesis particle size, low yield, limited growth space, etc., to achieve uniform and high-quality synthesis , fully absorb, prevent the effect of ginseng

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

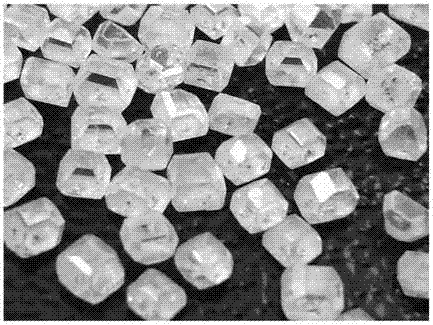

Image

Examples

Embodiment 1

[0056] A kind of synthetic method of gem grade colorless diamond, comprises the following steps:

[0057] (1) Preparation of diamond growth layer:

[0058] Take the Fe-based metal catalyst Fe with a particle size of 10-50 μm 65 Ni 30 co 5 , natural graphite with a particle size of 5-40 μm (purity ≥ 99.99%) and trace element Cu (purity ≥ 99.9%) are mixed according to a mass ratio of 50:50:0.5, and then the above-mentioned mixture is added to the three-dimensional mixer Mix under room temperature for 12 hours, carry out isostatic pressing 240Mpa, granulate (particle diameter is 4~6mm), be pressed into the cylindrical diamond growth layer that thickness is 10mm, diameter is 40mm; High vacuum reduction at 850°C for 24 hours, after the reduction is completed, the temperature is naturally cooled to room temperature, and then vacuum packaged for use;

[0059] (2) Preparation of diamond synthesis column:

[0060] ①.Using conventional methods to prepare high-purity magnesium oxide...

Embodiment 2

[0078] A kind of synthetic method of gem grade colorless diamond, comprises the following steps:

[0079] (1) Preparation of diamond growth layer:

[0080] Take the Fe-based metal catalyst Fe with a particle size of 2-40 μm 65 Ni 30 co 5 , high-purity graphite (purity ≥ 99.99%) with a particle size of 2-40 μm and trace element Cu (purity ≥ 99.9%) are mixed according to a mass ratio of 70:30:1, and then the above-mentioned mixture is added to the three-dimensional mixer Mix at medium temperature for 12 hours, carry out isostatic pressing at 240Mpa, granulate (particle size is 4-6mm), and press into a cylindrical diamond growth layer with a thickness of 8mm and a diameter of 40mm; after the pressing is completed, the prepared diamond growth layer Under the condition of a temperature of 800°C, it was reduced in a high vacuum for 24 hours. After the reduction was completed, the temperature was naturally cooled to room temperature, and then vacuum-packed for use;

[0081] (2) P...

Embodiment 3

[0100] A kind of synthetic method of gem grade colorless diamond, comprises the following steps:

[0101] (1) Preparation of diamond growth layer:

[0102] Take the Fe-based metal catalyst Fe with a particle size of 2-50 μm 70 Ni 29 co 1 , natural graphite (purity ≥ 99.99%) with a particle size of 2 to 40 μm and trace element Ti (purity ≥ 99.9%) are mixed according to a mass ratio of 50:50:0.5, and then the above-mentioned mixture is added to the three-dimensional mixer Mix under room temperature for 16 hours, carry out isostatic pressing 300Mpa, granulate (particle diameter is 4~6mm), be pressed into the cylindrical diamond growth layer that height is 25mm, diameter is 35mm; High vacuum reduction at 900°C for 30 hours, after the reduction is completed, the temperature is naturally cooled to room temperature, and then vacuum packaged for later use;

[0103] (2) Preparation of diamond synthesis column:

[0104] ①.Using conventional methods to prepare high-purity magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com