Honeysuckle antibacterial composition, preparation method, and application thereof

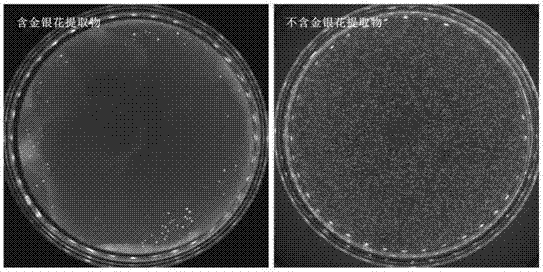

An antibacterial composition, honeysuckle extract technology, applied in the field of natural medicine preparation, can solve problems such as immature market, achieve high safety, solve skin infection, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation of honeysuckle antibacterial ointment

[0036] Honeysuckle extract 10g, stearic acid 10g, glyceryl monostearate 2.5g, glycerin 10g, potassium carbonate 0.9g, triethanolamine 0.3ml, and the balance is pure water.

[0037] The preparation method is as follows: take the matrix prepared by the emulsification method, add honeysuckle extract, mix well to obtain the honeysuckle antibacterial ointment, sterilize and seal.

Embodiment 2

[0038] Embodiment 2: the preparation of honeysuckle antibacterial gel

[0039] Honeysuckle extract 10g, glycerin 9g, carbomer 9403g, pure water 100ml, triethanolamine amount.

[0040] The preparation method is as follows: dissolve honeysuckle extract and glycerin in pure water successively to obtain a uniform solution, take Carbomer 940 and evenly disperse in the above solution, stir well, add triethanolamine to adjust the pH to 6.8-7.2, and after sterilization Encapsulation is enough.

Embodiment 3

[0041] Embodiment 3: the preparation of honeysuckle antibacterial gel ointment

[0042] Honeysuckle extract 10g, glycerin 7.7g, carbomer C-934 2.4g, PVP 6g, gelatin 0.5g, appropriate amount of triethanolamine, and the balance is pure water.

[0043] The preparation method is as follows: soak the carbomer with 3 times the amount of glycerin, add pure water to make a 3% concentration of carbomer gel, and adjust the pH value to 7.0 with triethanolamine (I); prepare glycerin gelatin in the usual way (II) Dissolve PVP in an appropriate amount of pure water to make a 50% PVP aqueous solution (Ⅲ); mix the honeysuckle extract with Ⅰ, grind it evenly, and then add it to the mixture of Ⅱ and Ⅲ that has been preheated and mixed in a 60°C water bath. Grind and mix evenly to make a uniform paste, spread the above-mentioned evenly stirred paste on the non-woven fabric backing, press properly to make a paste of 0.25g / cm 2 , dried in an oven at 45°C-50°C until the weight of the paste is 0.10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com