A method for improving the inclusion performance of pharmaceutical excipients β-cyclodextrin

An auxiliary material package and cyclodextrin technology, which is applied in the directions of pharmaceutical formulations, organic active ingredients, and non-active ingredients medical preparations, etc., can solve the problem of low inclusion rate, insufficient stability of inclusion compounds, and low inclusion rate of cyclodextrin. and other problems, to achieve the effect of improving the inclusion rate and facilitating the inclusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

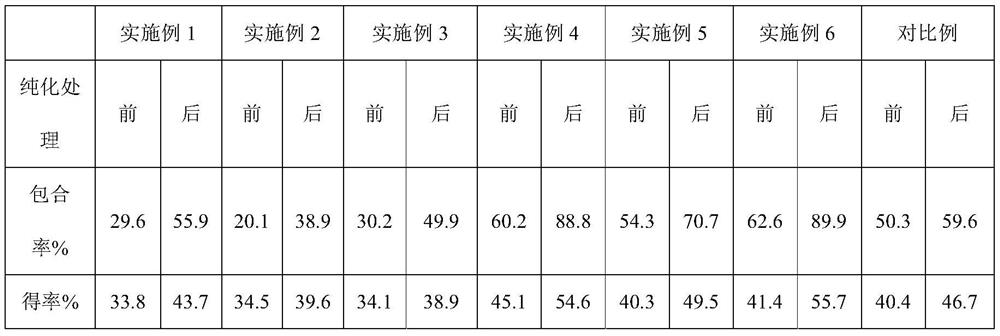

Embodiment 1

[0016] (1) Recrystallize β-cyclodextrin with purified water, dry at 60°C for 12 hours, and set aside; (2) Use saturated solution method, use mixed solvent (water:[EMIM]Cl=9.5:0.5 (weight ratio)) After preparing 27 mL of the saturated solution of purified β-cyclodextrin, add the drug naproxen, wherein the drug naproxen and the purified β-cyclodextrin are in a solid-to-solid molar ratio of 1:3, and stirred at 70°C for 2 hours (3) Measure the inclusion rate of the inclusion compound by ultraviolet spectrophotometry, and compare the inclusion effect of the inclusion compound before and after purification.

Embodiment 2

[0018] (1) Purify β-cyclodextrin with ethanol, dry it at 60°C for 12 hours, and set aside; (2) Use a saturated solution method, use 27 mL of a mixed solvent (water:[EMIM]Cl=9:1 (weight ratio)) After preparing a saturated solution of the purified β-cyclodextrin, add the drug naproxen, wherein the drug naproxen and the purified β-cyclodextrin are stirred at 70° C. for 2 hours at a solid-to-solid molar ratio of 1:3 3) Measure the inclusion rate of the inclusion compound by ultraviolet spectrophotometry, and compare the inclusion effect of the inclusion compound before and after purification.

Embodiment 3

[0020] (1) Purify β-cyclodextrin with acetone, dry it at 60°C for 12 hours, and set aside; (2) Use saturated solution method, use 27 mL of mixed solvent (water:[EMIM]Cl=8:2 (weight ratio)) After preparing a saturated solution of the purified β-cyclodextrin, add the drug naproxen, wherein the drug naproxen and the purified β-cyclodextrin are stirred at 70° C. for 2 hours at a solid-to-solid molar ratio of 1:3 (3) Measure the inclusion rate of the inclusion compound by ultraviolet spectrophotometry, and compare the inclusion effect of the inclusion compound before and after purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com