A kind of porous cross-linked polyurea microsphere, its preparation method and application

A technology of cross-linked polyurea and microspheres, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of complex preparation process, waste gas and waste liquid pollution, etc., and achieve easy raw materials Good results, good repeatability and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

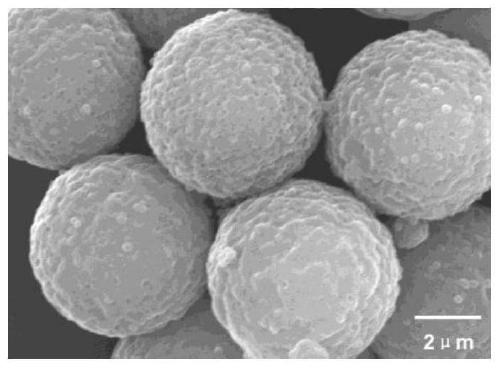

[0032] The preparation method of porous cross-linked polyurea microsphere provided by the invention comprises the following steps:

[0033] Disperse monodisperse silica particles in a mixed solvent composed of acetone and water, stir with a glass rod and disperse ultrasonically for 12-17 minutes to obtain a uniformly dispersed silica dispersion;

[0034] Add pre-polymerized monomer isophorone diisocyanate (IPDI) to the silica dispersion, shake for 0.5-1.5min to make it evenly dispersed, and then react at 25-35°C for 0.8-1.2 hours before adding to the reaction The cross-linking agent triethylenetetramine (TETA) is added dropwise in the liquid, and after the addition is completed, fully react for 0.8-1.2 hours to obtain a solution containing porous cross-linked polyurea microspheres, which is centrifuged, and the filter residue is washed with acetone / water, that is Porous cross-linked polyurea microspheres.

[0035] The mass ratio of the monodisperse silica particles, acetone, ...

Embodiment 1

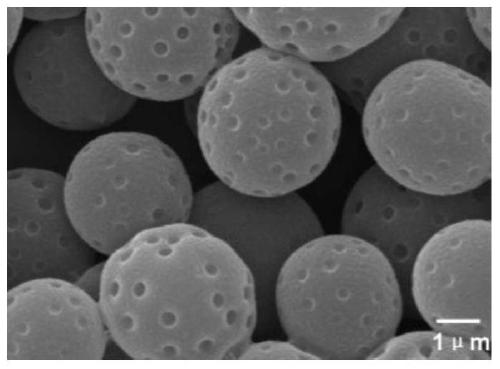

[0038] The porous cross-linked polyurea microspheres of this embodiment have a surface microporous structure, and the average pore diameter of the surface micropores is 0.3 μm.

[0039] The preparation method of above-mentioned porous cross-linked polyurea microspheres, comprises the following steps:

[0040] S1. Disperse 0.5 g of monodisperse silica particles with an average particle size of 375 nm in a mixed solvent composed of 66.5 g of acetone and 28.5 g of water, stir with a glass rod and disperse ultrasonically for 15 minutes to obtain a uniformly dispersed silica dispersion .

[0041] S2. Add 5 g of monomeric isophorone diisocyanate (IPDI) to the monodisperse silica dispersion, shake it for 1 minute to make it evenly dispersed, and then let it stand at 30° C. for 1 hour to react.

[0042] S3. Add 1.644 g of crosslinking agent triethylenetetramine TETA dropwise to the solution after 1 hour of reaction. After the dropwise addition, fully react for 1 hour to obtain a solu...

Embodiment 2

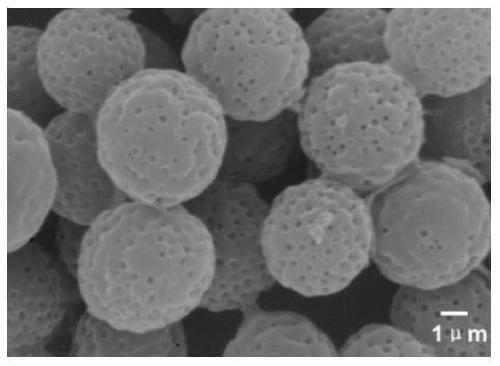

[0047] The porous cross-linked polyurea microspheres of this embodiment have a surface microporous structure, and the average pore diameter of the surface micropores is 0.3 μm.

[0048] The preparation method of the porous cross-linked polyurea microspheres of the present embodiment comprises the following steps:

[0049] S1. Disperse 1.2 g of monodisperse silica particles with an average particle size of 375 nm in a solvent composed of 66.5 g of acetone and 28.5 g of water, stir with a glass rod and disperse ultrasonically for 15 minutes to obtain a uniformly dispersed silica dispersion.

[0050] S2. Add 5 g of monomeric isophorone diisocyanate IPDI to the monodisperse silica dispersion, shake it for 1 minute to make it evenly dispersed, and then stand it at 30° C. for 1 hour to react.

[0051] S3. Add 1.644 g of crosslinking agent triethylenetetramine TETA dropwise to the solution after 1 hour of reaction. After the dropwise addition, fully react for 1 hour to obtain a solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com