Odor remover, low-odor polyolefin plastic and method for their preparation

An odor removal and polyolefin technology, applied in the field of low odor polyolefin plastic and its preparation, can solve problems such as adverse health and environmental effects, interfere with the fragrance of daily chemical products, and affect consumers' senses, so as to reduce odor and maintain mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1-8

[0030] 1. Preparation of odor remover:

[0031] Odor remover 1#: Stir and react 5kg of β-CD and 5kg of PY88 at 120°C for 2 hours, cool to room temperature, and granulate to obtain the odor remover;

[0032] Odor remover 2#: Stir and react 3kg of β-CD and 7kg of PY88 at 80°C for 5 hours, cool to room temperature, and granulate to obtain the odor remover;

[0033] Odor remover 3#: 7 kg of β-CD and 3 kg of PY88 were stirred and reacted at 150° C. for 1 hour, cooled to room temperature, and granulated to obtain an odor remover.

[0034] 2. Preparation of polyolefin plastics

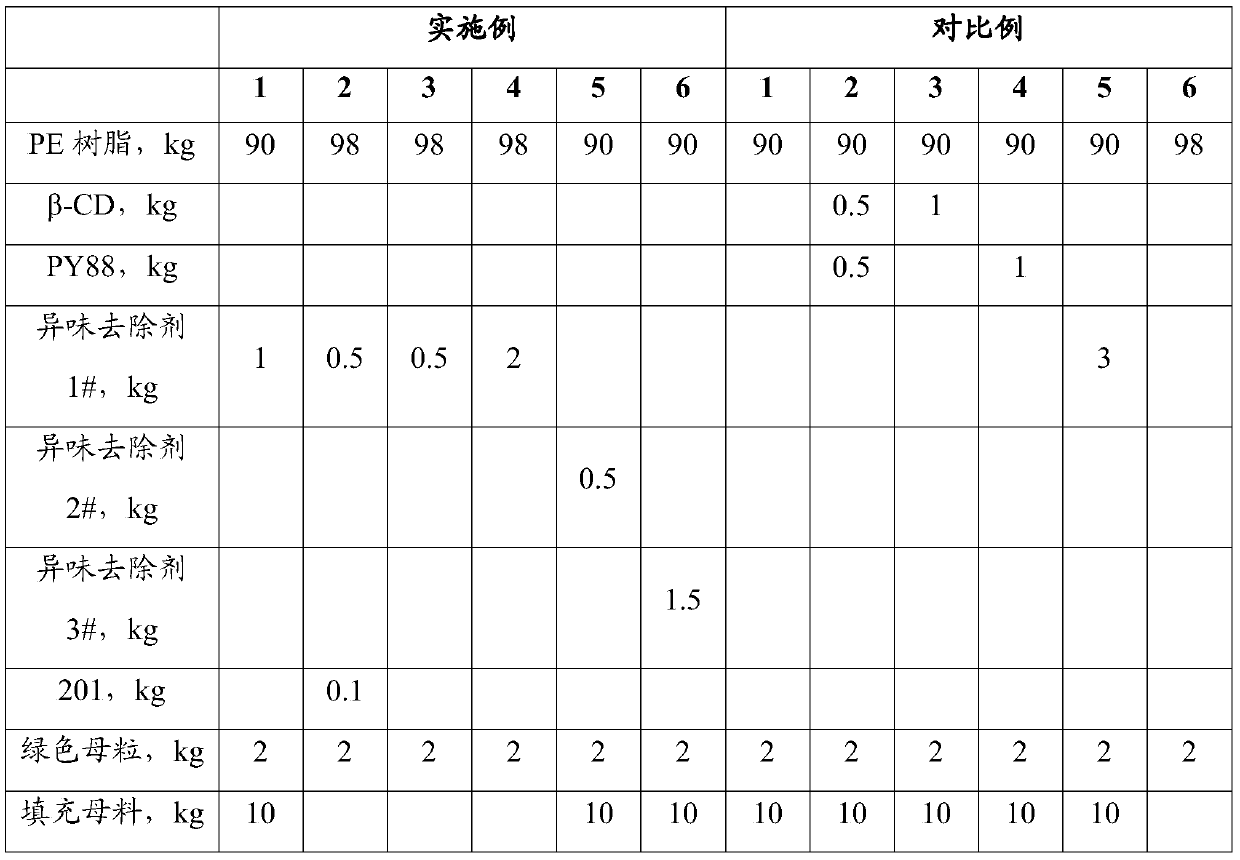

[0035] Take each raw material according to the weight of Table 1 and Table 2; Under normal temperature and pressure, the above-mentioned raw materials are mixed uniformly in a high-speed mixer; 350 revolutions per minute, the extrusion temperature is 180° C., and PE plastics and PP plastics are prepared.

[0036] Table 1 Preparation of PE plastic

[0037]

[0038] Table 2 Preparation of PP plastic

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com