Reinforced toughened melamine mold plastics and preparation method

A melamine molding compound and a technology for strengthening and toughening are applied in the field of strengthening and toughening melamine molding compound and its preparation, and can solve the problems of broken melamine tableware and shortening of service life of tableware.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A kind of preparation method of strengthening and toughening melamine molding compound as described above, described preparation method comprises the steps:

[0038] (1) In the modified melamine formaldehyde resin obtained, triethanolamine is also added in proportion, the pH value is adjusted, the reaction is terminated and cooled to 70° C.;

[0039] (2) Kneading: Add wood cellulose, lubricant, glass fiber and the above-mentioned modified melamine formaldehyde resin in proportion to kneading together in the Z-type low-speed kneader, change the stirring direction regularly, and stir until uniform;

[0040] (3) Drying: use multi-section mesh belt hot air oven, 80-85 ℃ hot air drying, drying must be uniform, control moisture below 3.5%, drying time is about 3-4 hours;

[0041] (4) Pulverizing and ball milling: After the material is pulverized, enter the ball mill for 3-8 hours, add curing agent and pigment in this process, and complete the requirements of material densific...

Embodiment 1

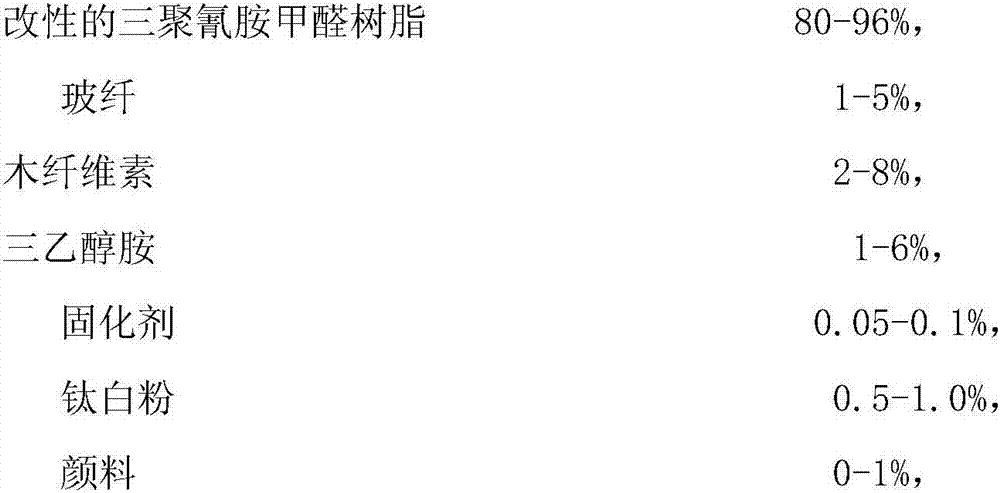

[0043] Embodiment 1: The reinforced and toughened melamine molding compound of the present invention is formed by the following raw materials in the following mass percentage proportioning:

[0044]

[0045] Described modified melamine formaldehyde resin is made by following production method:

[0046] (1) Add 100 parts by mass of formaldehyde solution into the reactor, and adjust the pH value to 8.5 by adding sodium hydroxide;

[0047] (2) Addition reaction: Add 10 parts by mass of THEIC and 10 parts by mass of PEG and start to heat up, while heating up, add 90 parts by mass of melamine and heat up to 85°C for reaction;

[0048] (3) After keeping the temperature at 85° C. for 15 minutes, add 10 parts by mass of p-toluenesulfonamide, and raise the temperature to 82° C. to react to the end.

[0049] (4) Polycondensation reaction: when the resin has white precipitation with 4°C water test, the temperature is lowered to 75°C, the pH value is adjusted to 8.2, and the reaction ...

Embodiment 2

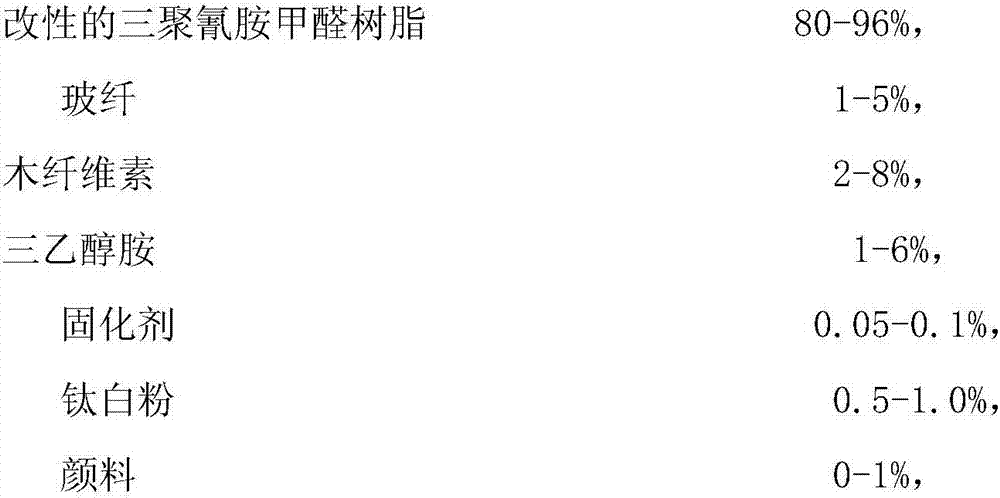

[0056] Embodiment 2: A kind of reinforced and toughened melamine molding compound according to the present invention, said melamine molding compound is made of the following raw materials through the following mass percentage ratio:

[0057]

[0058]

[0059] Described modified melamine formaldehyde resin is made by following production method:

[0060] (1) Add 100 parts by mass of formaldehyde solution into the reactor, and adjust the pH value to 8 by adding sodium hydroxide;

[0061](2) Addition reaction: add 5 parts by mass of THEIC and 5 parts by mass of PEG and start to heat up, while heating up, add 80 parts by mass of melamine and heat up to 80°C for reaction;

[0062] (3) After keeping the temperature at 80° C. for 10 minutes, add 5 parts by mass of p-toluenesulfonamide, and raise the temperature to 85° C. to react to the end point.

[0063] (4) Polycondensation reaction: When the resin has white precipitation with 4°C water test, lower the temperature to 75°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com